Method for reducing pollutant discharge in phenol-acetone production

A technology for pollutant discharge and phenol acetone, which is applied in the fields of water pollutants, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of many waste water discharge nodes, high treatment costs, and difficult water treatment, and achieve significant resource recovery. and pollutant emission reduction effect, reducing difficulty, improving raw material utilization rate and product yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

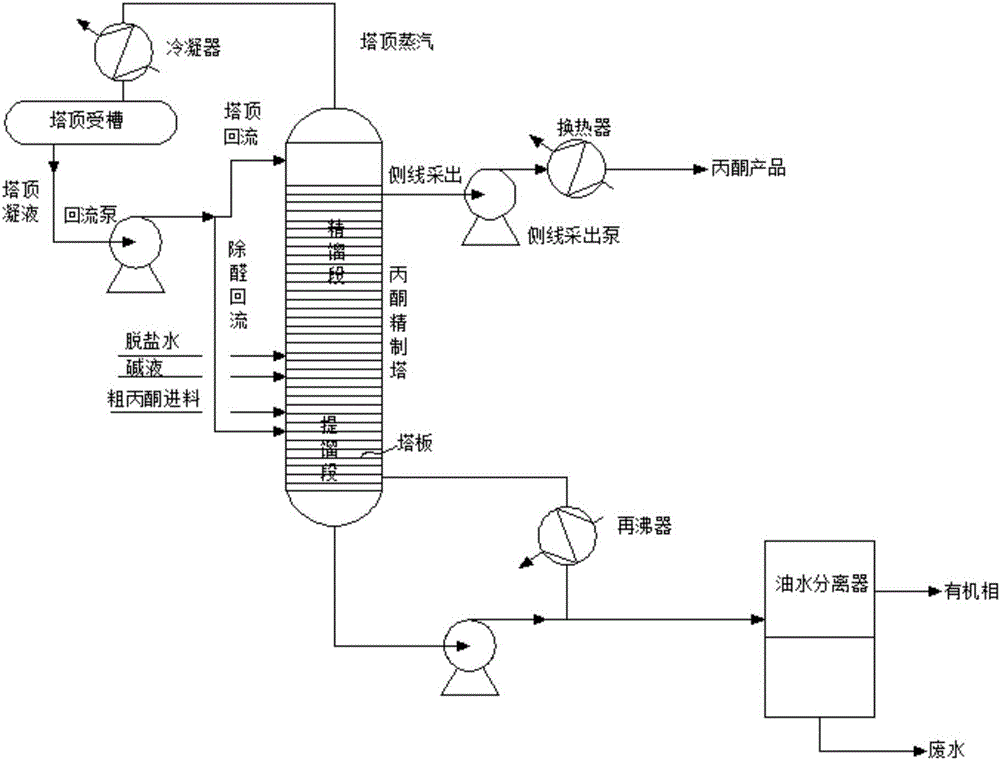

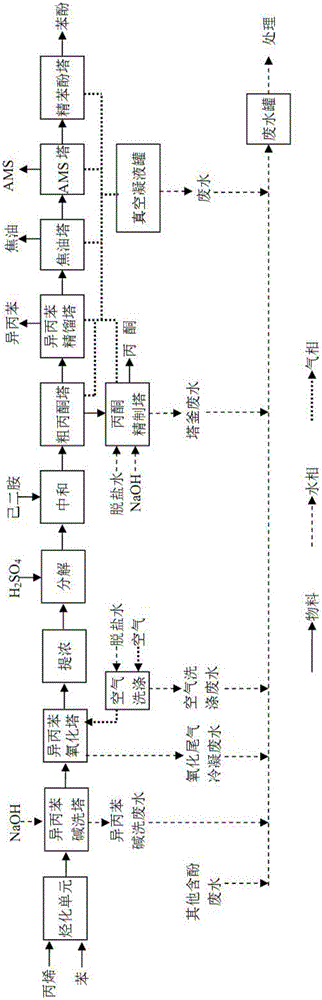

[0048] Adopt traditional cumene method to prepare phenol acetone (see figure 1 ), and its total drainage COD reaches 4000-8000mg / L.

[0049] The method of the present application carries out at least one of following transformations to traditional cumene method and device:

[0050] (1) An independent vacuum system is established in the acetone refining tower, and the pressure at the top of the tower is reduced by 15kPa, and a thin-layer structured packing is installed in the thickness of the liquid layer of the tray below the lye feed inlet (see image 3 , Figure 5 ), the reflux rate at the top of the tower and the reflux rate for removing aldehydes are reduced by 25%. Under the condition of ensuring the product quality of the side line, the steam consumption of the acetone refining tower tower is reduced by 20%, and the acetone content in the tower reactor is reduced from 2200mg / L to 520mg / L L.

[0051] (2) After the phenolic waste water is collected by the phenolic waste...

Embodiment 2

[0056] The method of the application carries out following transformation to traditional cumene method and device:

[0057] (1)~(4) item transformation is the same as embodiment 1.

[0058] (5) The total drainage of the device is treated with oil separation. After the treatment, the COD of the wastewater is 1800mg / L, and then it is treated with an aerobic biological fluidized bed, and the COD is removed by 87%. Use PAC and PAM as coagulants and coagulants for coagulation and sedimentation treatment, and then use H 2 o 2 Enhanced degradation treatment for oxidant, the dosage is 250mg / L, ferrous ion is used as the catalyst, the dosage is 50mg / L, the COD of the treated effluent is below 50mg / L, and phenol and acetone are not detected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of recovery | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com