Preparation method of carboxymethyl cellulose fiber

A technology of carboxymethyl cellulose and cellulose fibers, applied in the field of preparation of carboxymethyl cellulose fibers, can solve problems such as insoluble carboxymethyl cellulose, increase wettability and adsorption, and reduce the growth of bacteria , good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 A kind of preparation method of carboxymethyl cellulose fiber, comprises the following steps:

[0048] A method for preparing carboxymethyl cellulose fibers, comprising the steps of alkalization, etherification and post-treatment.

[0049] S1, alkalization

[0050] The viscose fiber is basified with sodium hydroxide in anhydrous ethanol and water to form alkali cellulose fiber.

[0051] The ratio of the absolute ethanol to water is 58:1.5; the ratio of the viscose fiber to the solvent is 12.5:59.5; the addition of the sodium hydroxide is 16% of the viscose fiber.

[0052] The fineness of the viscose fiber is 3dtex, and the cut length is 38mm.

[0053] Preferably, the temperature of the alkalization reaction is 45° C., and the reaction time is 60 minutes.

[0054] S2, etherification

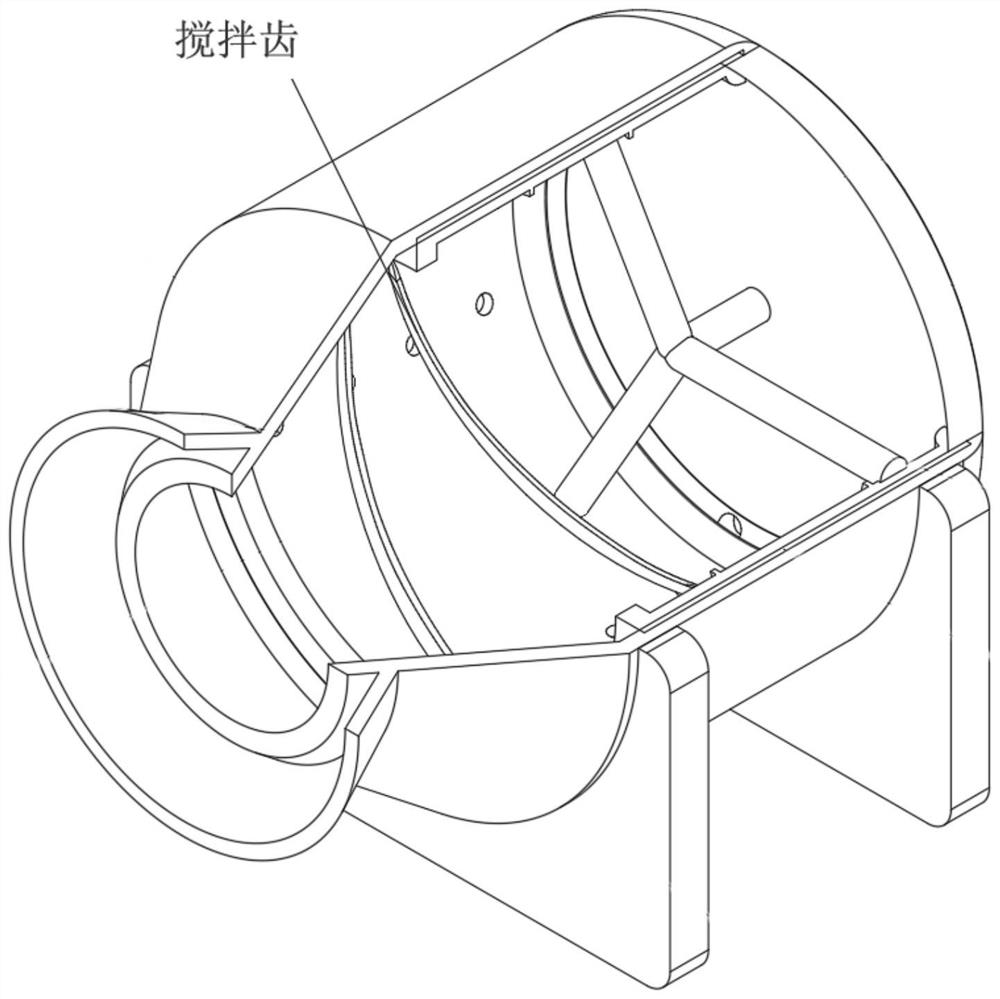

[0055] Put the alkali cellulose fibers in a stirring reaction pot, add monochloroacetic acid and absolute ethanol, then add cetyltrimethylammonium bromide, start the stirri...

Embodiment 2

[0068] Embodiment 2 A kind of preparation method of carboxymethyl cellulose fiber, comprises the following steps:

[0069] A method for preparing carboxymethyl cellulose fibers, comprising the steps of alkalization, etherification and post-treatment.

[0070] S1, alkalization

[0071] The viscose fiber is basified with sodium hydroxide in anhydrous ethanol and water to form alkali cellulose fiber.

[0072] The ratio of the absolute ethanol to water is 55:1.2; the ratio of the viscose fiber to the solvent is 12:59; the added amount of the sodium hydroxide is 15% of the viscose fiber.

[0073] The fineness of the viscose fiber is 1.1 dtex, and the cut length is 16 mm.

[0074] Preferably, the temperature of the alkalization reaction is 40° C., and the reaction time is 70 minutes.

[0075] S2, etherification

[0076] Put the alkali cellulose fibers in a stirring reaction pot, add monochloroacetic acid and absolute ethanol, then add cetyltrimethylammonium bromide, start the st...

Embodiment 3

[0089] Embodiment 3 A kind of preparation method of carboxymethyl cellulose fiber, comprises the following steps:

[0090] A method for preparing carboxymethyl cellulose fibers, comprising the steps of alkalization, etherification and post-treatment.

[0091] S1, alkalization

[0092] The viscose fiber is basified with sodium hydroxide in anhydrous ethanol and water to form alkali cellulose fiber.

[0093] The ratio of the absolute ethanol to water is 60:1.7; the ratio of the viscose fiber to the solvent is 13:60; the added amount of the sodium hydroxide is 18% of the viscose fiber.

[0094] The fineness of the viscose fiber is 6.6dtex, and the cut length is 76mm.

[0095] Preferably, the temperature of the alkalization reaction is 50° C., and the reaction time is 50 minutes.

[0096] S2, etherification

[0097] Put the alkali cellulose fibers in a stirring reaction pot, add monochloroacetic acid and absolute ethanol, then add cetyltrimethylammonium bromide, start the stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com