Light aluminum alloy wheel box

An aluminum alloy, light-weight technology, which is applied in the direction of wheels, wheel axle combinations, and wheels characterized by track running parts, can solve the problems of scrap replacement, easy wear of threaded holes, and non-adjustable positions, so as to save costs and time , The effect of preventing the bolt from rotating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

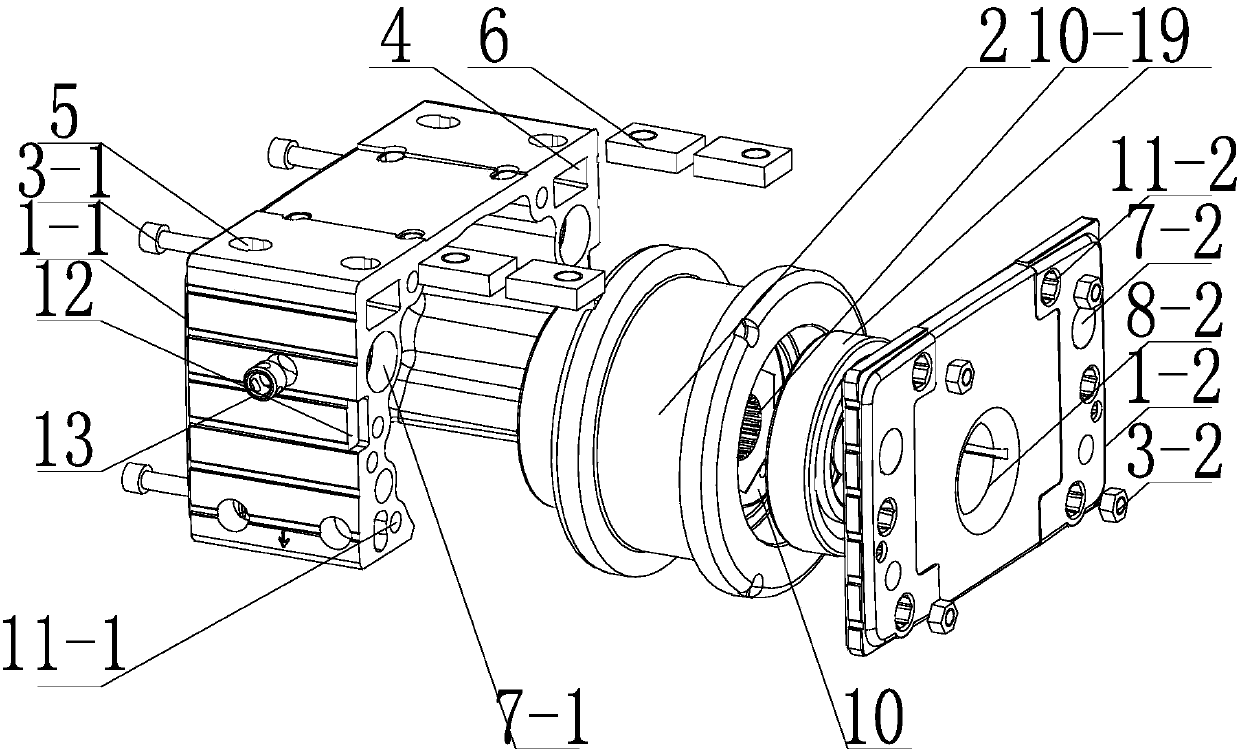

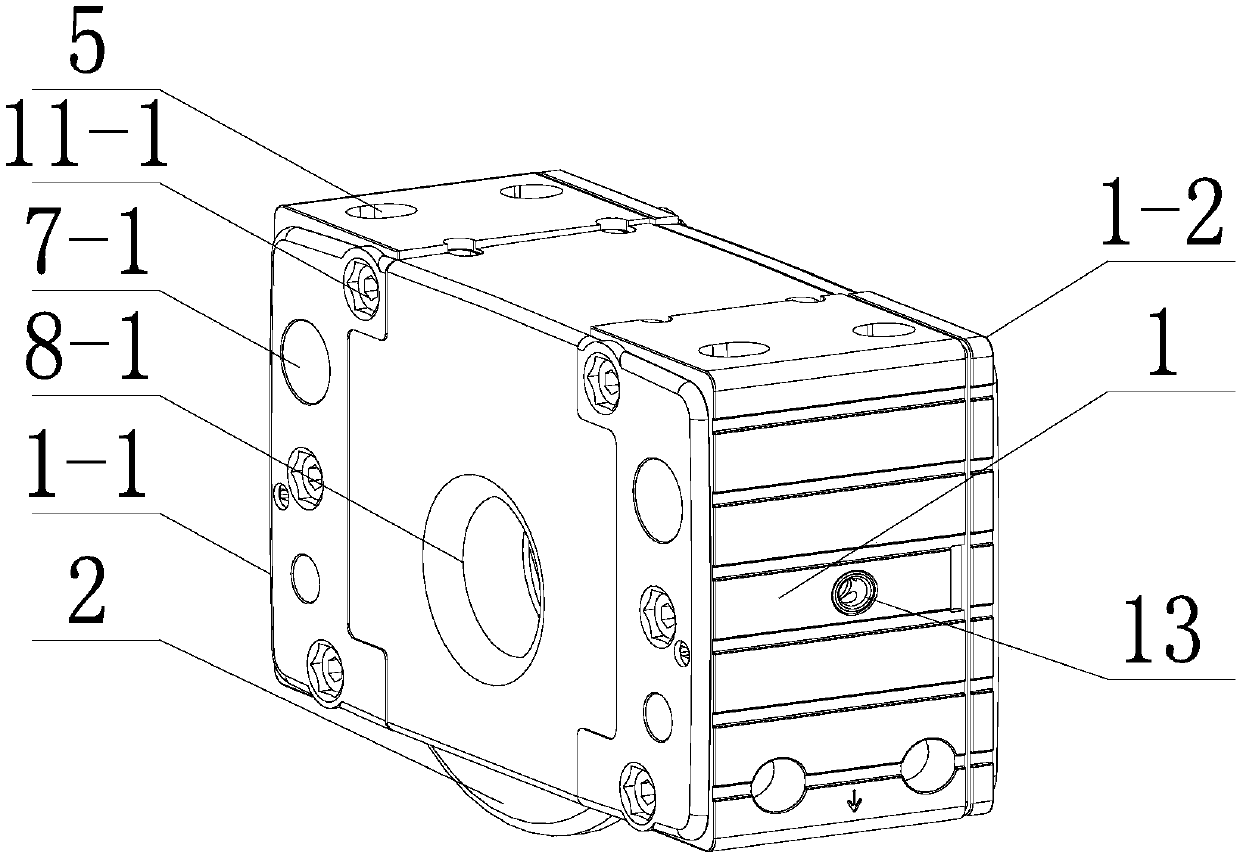

[0032] The present invention will be further described in detail below through specific embodiments.

[0033] Reference attached figure 1 and attached figure 2 , in this embodiment, a light-duty aluminum alloy wheel box is provided, which includes a box body 1 and a wheel 2 rotatably connected to the box body 1. The box body 1 is covered by a box cover 1-2 and closed on the side of the box shell 1-1. The box cover 1-2 and the box shell 1-1 are inserted through the round head screw 3-1 and fastened together with the nut 3-2 screwed on the round head screw 3-1. A slider square hole 4 is opened on the left and right sides of the upper end of the contact surface with the box cover 1-2, and two elliptical through holes 5 are opened above each slider square hole 4, and each slider square hole 4 is in the middle. Both are placed with two square slides 6 tapped with threaded holes.

[0034] In this embodiment, the number of round head screws 3-1 is preferably six, the number of nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com