System and method for increasing yield of low-carbon olefins

A technology for low-carbon olefins and carbon tetra-olefins, which is applied in chemical instruments and methods, hydrocarbon purification/separation, processing of hydrocarbon oils, etc. Improve comprehensive competitiveness and economic benefits, and promote the effect of application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

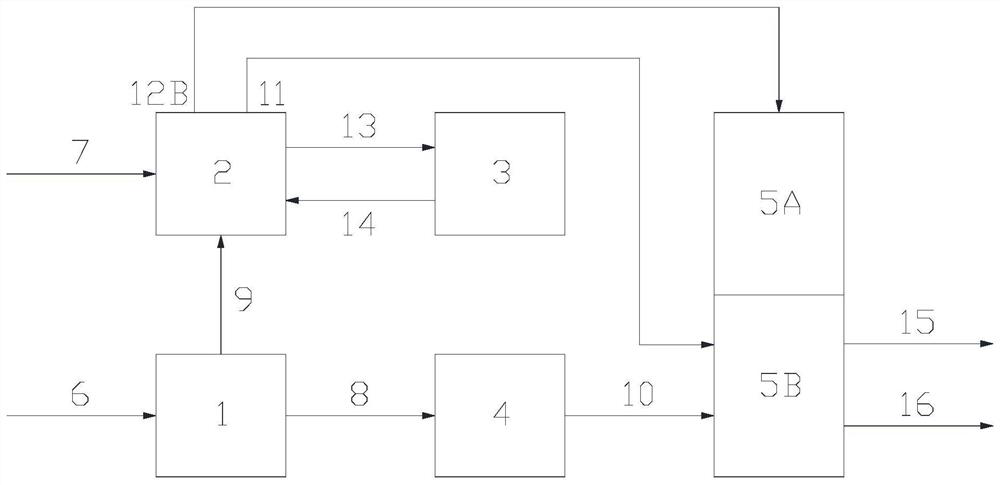

[0063] This example is used to illustrate the system and method for increasing the production of light olefins of the present invention.

[0064] like figure 1 As shown, the system includes: extraction unit 1, hydrogenation separation unit 2, normalization unit 3, olefin catalytic cracking unit 4, ethylene plant cracking unit 5A and ethylene plant separation unit 5B; unsaturated C4 raw material feed The pipeline is connected with the extraction unit 1; the saturated carbon four raw material feed line is connected with the hydrogenation separation unit 2; the extraction unit 1 is connected with the hydrogenation separation unit through the extraction unit C4 alkane discharge pipeline 2 are connected; the extraction unit 1 is connected with the olefin catalytic cracking unit 4 through the extraction unit carbon tetraolefin discharge pipeline; the hydrogenation separation unit 2 is connected with the normalization unit through the isobutane-rich discharge pipeline Unit 3 is con...

comparative approach 1-2

[0075] Since the rich olefin C4 cannot directly enter into ethylene cracking (causing coking), it can only be burned as fuel. Therefore, comparison scheme 1 is used as fuel gas, and comparison scheme 2 is for the production of high-octane alkylate oil. The comparison of income per ton is shown in Table 1 below.

[0076] Table 1 C4 income per ton of different processing schemes

[0077]

[0078] Note: Triene yield is the sum of the yields of ethylene, propylene, and butadiene.

Embodiment 2

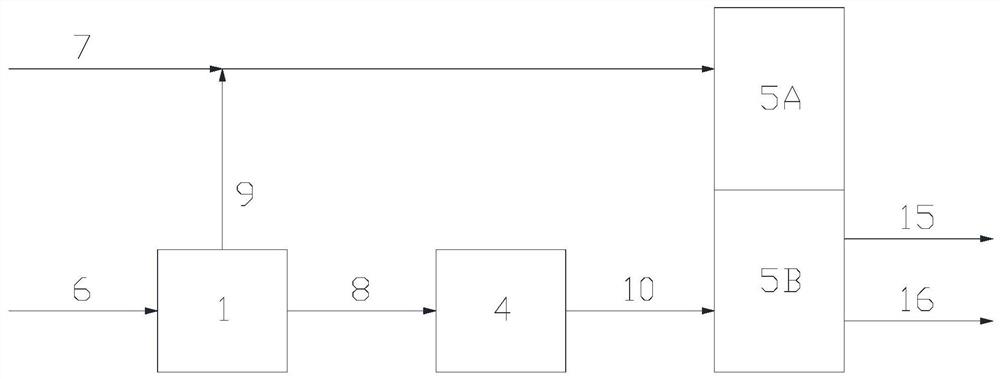

[0080] This example is used to illustrate the system and method for increasing the production of light olefins of the present invention.

[0081] like figure 2 As shown, the system includes: extraction unit 1, hydrogenation separation unit 2, olefin catalytic cracking unit 4, ethylene plant cracking unit 5A and ethylene plant separation unit 5B; Unit 1 is connected; the saturated carbon four raw material feed line is connected with the hydrogenation separation unit 2; the extraction unit 1 is connected with the hydrogenation separation unit 2 through the extraction unit carbon four alkane discharge pipeline; the extraction The extraction unit 1 is connected to the olefin catalytic cracking unit 4 through the C4 olefin discharge pipeline of the extraction unit; the hydrogenation separation unit 2 is connected to the ethylene unit through the hydrogenation tail gas discharge pipeline and the butane-rich discharge pipeline respectively. The separation unit 5B is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com