Manufacturing method of high-quality quartz crucible

A technology for a quartz crucible and a manufacturing method, which is applied to chemical instruments and methods, manufacturing tools, glass molding, etc., can solve the problems of high cost, limited quality of quartz crucibles, limited current size, etc., so as to improve production quality and reduce collapse. rate, the effect of reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

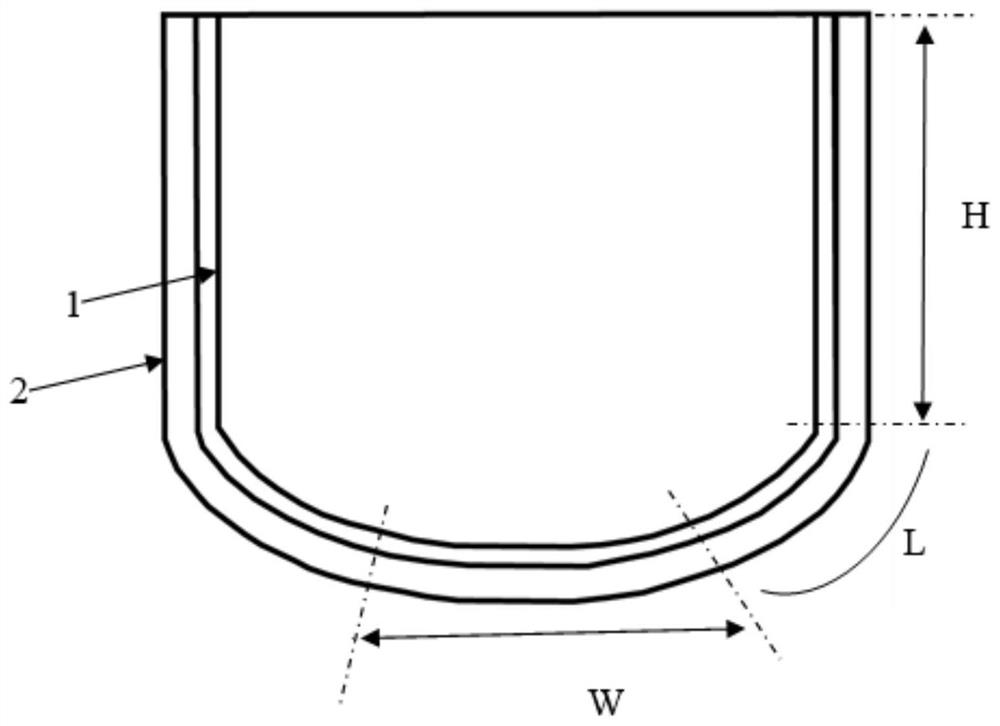

[0060] The present embodiment provides a high-quality quartz crucible production method for making an outer diameter of 26 inches of quartz crucible, using a vacuum arc method, the steps are as follows:

[0061] (1) Uniformly distribute high-purity quartz sand powder in the crucible mold and form;

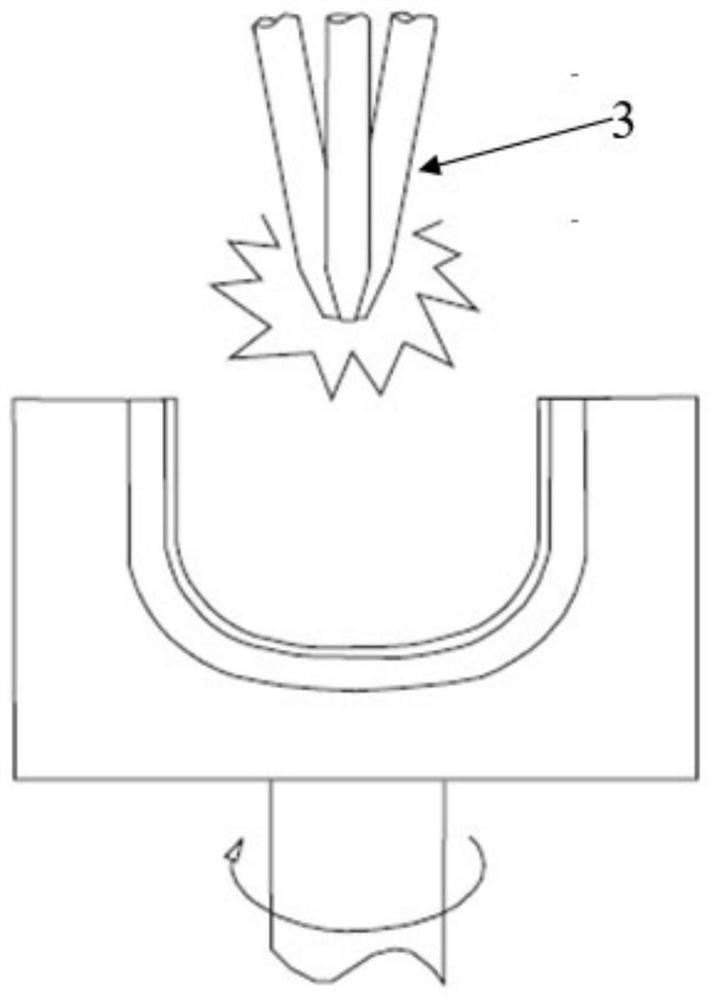

[0062] (2) The mold after molding is moved into the arc melting furnace;

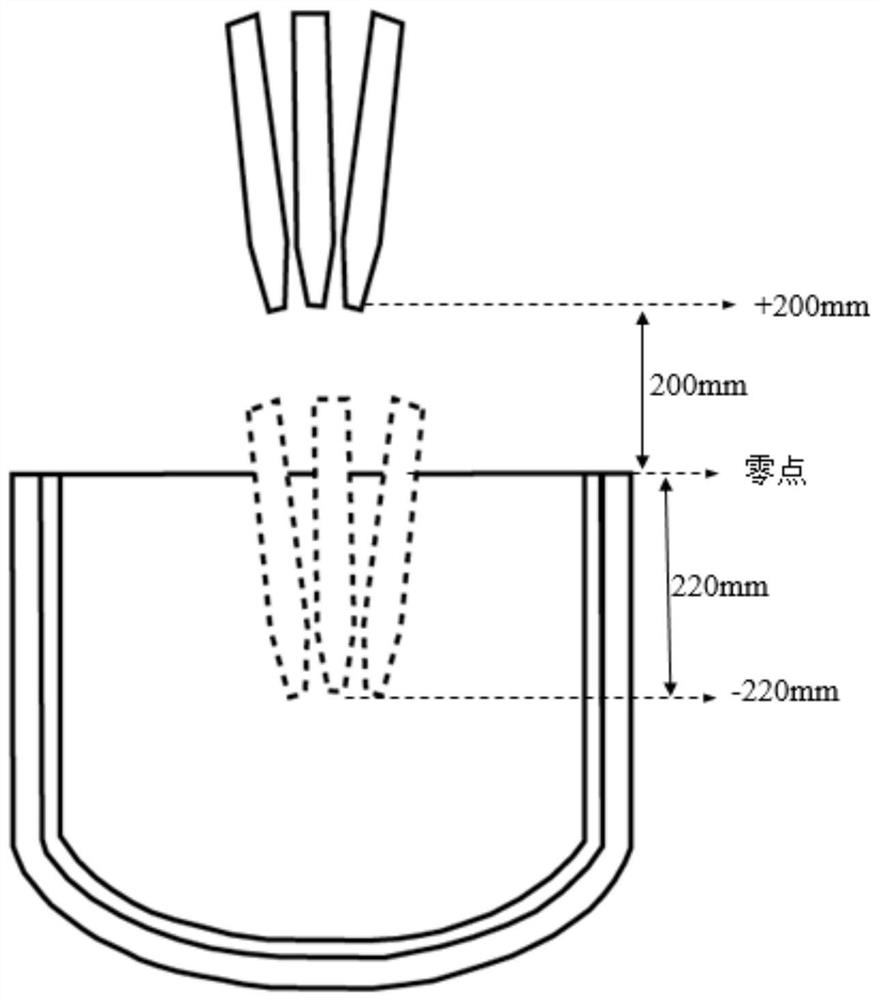

[0063] (3) Set the position of the upper end face of the mold to zero, and the PLC program controls the position of the graphite electrode Figure 4 As shown, the quartz crucible is melted. In the figure, the graphite electrode works in a total of 7 positions, the starting position stays for 3min, the second position stays for 3min, the third position stays for 3min, the fourth position stays for 1.8min, the fifth position stays for 1.8min, the bottom polishing position stays for 3.6min (310mm from the bottom of the crucible), and the tail sweeping station stays for 1.8min.

[0064] In the melting process, the po...

Embodiment 2

[0068] The present embodiment is based on Example 1, the PLC programmatically controls the positioning of the graphite electrode, such as Figure 5 As shown, the quartz crucible is melted. In the figure, the graphite electrode works in a total of 7 positions, the starting position stays for 3min, the second position stays for 2min, the third position stays for 3.1min, the fourth position stays for 2.7min, the fifth position stays for 1.8min, the bottom polishing position stays for 3.6min (300mm from the bottom of the crucible), and the tail sweeping station stays for 1.8min.

Embodiment 3

[0070] The present embodiment is based on Example 1, the PLC programmatically controls the positioning of the graphite electrode, such as Figure 6 As shown, the quartz crucible is melted. In the figure, the graphite electrode works in a total of 7 positions, the starting position stays for 3min, the second position stays for 2min, the third position stays for 2.2min, the fourth position stays for 3.6min, the fifth position stays for 1.8min, the bottom polishing position stays for 3.6min (350mm from the bottom of the crucible), and the tail sweeping station stays for 1.8min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com