Automotive PET (Polyethylene Terephthalate) sectional material air pipe and manufacturing method thereof

A manufacturing method and profile technology, which is applied in the field of automotive interiors, can solve problems such as difficult adjustment and adaptation, aging resistance, poor combustion resistance, and high hardness of the pipe body, so as to achieve effective installation adaptation, prolong service life, and adjustable sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

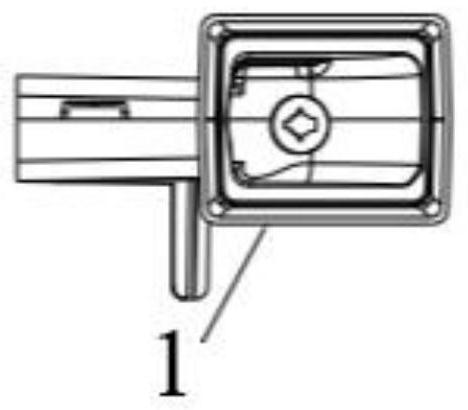

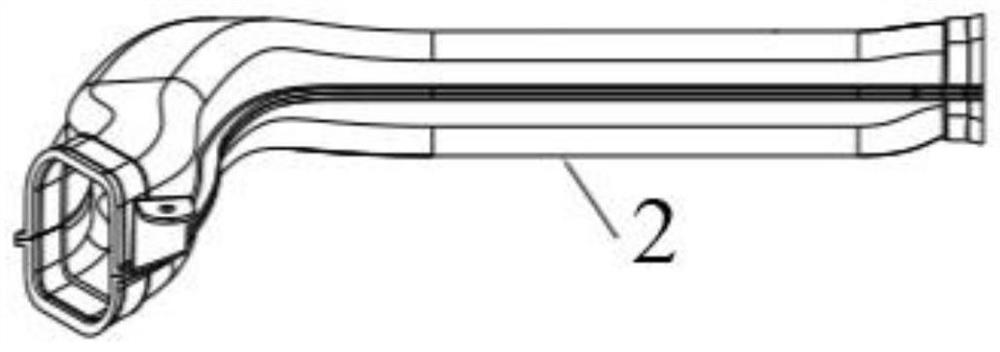

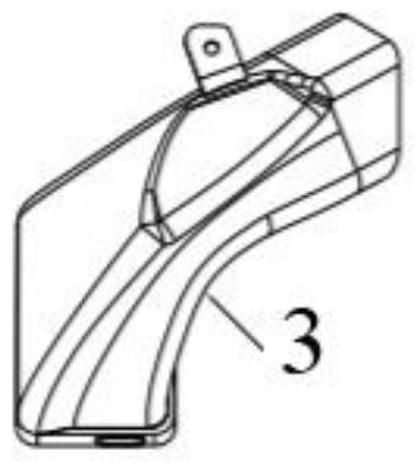

[0041] A kind of PET profile air duct for vehicle, such as Figure 1-6 As shown, it includes air outlet 1, pipe body 2 and interface 3; the air inlet port of pipe body 2 is connected to interface 3, and the air outlet port of pipe body 2 is connected to air outlet 1; air outlet 1 is made of PP material; interface 3 is made of HDPE material ;The tube body 2 is made of PET, the thickness of the tube body 2 is 12mm, and the density is 400g / cm 2 ;

[0042] The pipe body 2 is formed by butting the upper PET profile and the lower PET profile; the shapes of the upper PET profile and the lower PET profile are mirror images; the upper PET profile and the lower PET profile are hot-melt welded; Welding; pipe body 2 and interface 3 are welded by ultrasonic friction heat fusion.

[0043] The above-mentioned manufacturing method of a PET profile air duct for a vehicle comprises the following steps:

[0044] Step 1: Design the shape parameters of the air outlet 1, use the injection moldin...

Embodiment 2

[0053] A kind of PET profile air duct for vehicle, such as Figure 1-6 As shown, it includes air outlet 1, pipe body 2 and interface 3; the air inlet port of pipe body 2 is connected to interface 3, and the air outlet port of pipe body 2 is connected to air outlet 1; air outlet 1 is made of PP material; interface 3 is made of HDPE material ;The tube body 2 is made of PET, the thickness of the tube body 2 is 10mm, and the density is 410g / cm 2 ;

[0054] The pipe body 2 is formed by butting the upper PET profile and the lower PET profile; the shapes of the upper PET profile and the lower PET profile are mirror images; the upper PET profile and the lower PET profile are hot-melt welded; Welding; pipe body 2 and interface 3 are welded by ultrasonic friction heat fusion.

[0055] The above-mentioned manufacturing method of a PET profile air duct for a vehicle comprises the following steps:

[0056] Step 1: Design the shape parameters of the air outlet 1, use the injection moldin...

Embodiment 3

[0065] A kind of PET profile air duct for vehicle, such as Figure 1-6 As shown, it includes air outlet 1, pipe body 2 and interface 3; the air inlet port of pipe body 2 is connected to interface 3, and the air outlet port of pipe body 2 is connected to air outlet 1; air outlet 1 is made of PP material; interface 3 is made of HDPE material ;The tube body 2 is made of PET, the thickness of the tube body 2 is 13mm, and the density is 395g / cm 2 ;

[0066] The pipe body 2 is formed by butting the upper PET profile and the lower PET profile; the shapes of the upper PET profile and the lower PET profile are mirror images; the upper PET profile and the lower PET profile are hot-melt welded; Welding; pipe body 2 and interface 3 are welded by ultrasonic friction heat fusion.

[0067] The above-mentioned manufacturing method of a PET profile air duct for a vehicle comprises the following steps:

[0068] Step 1: Design the shape parameters of the air outlet 1, use the injection moldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com