Preparation method and application of supported iron-based catalyst

An iron-based catalyst, supported technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of deactivation, poor dispersion of active metals, easy growth and sintering reaction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

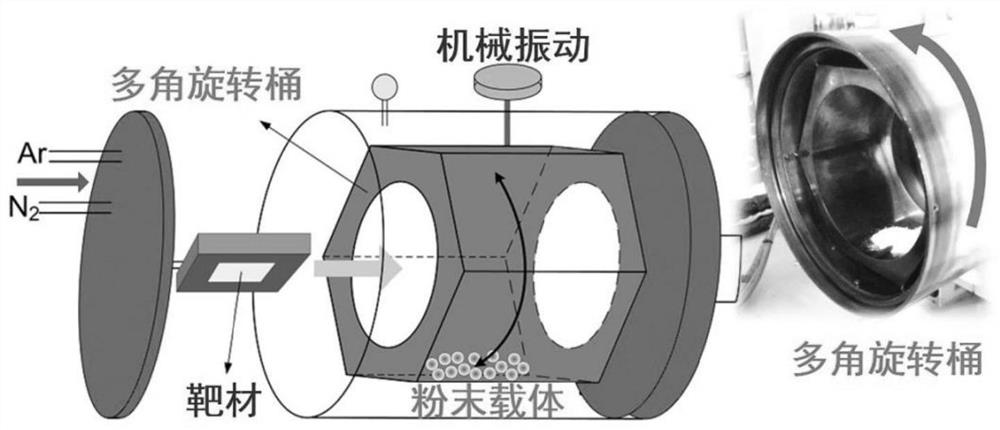

[0071] The preparation process of sp-Fe / HZSM-5 catalyst is as follows:

[0072] The catalyst was prepared by a multi-angle drum sputtering device, and the surface of the target was cleaned before preparation, and the iron target (mass purity above 99.9%) was bombarded with Ar ions generated by a plasma generator for 30 minutes;

[0073] Put the carrier powder HZSM-5 molecular sieve (silicon to aluminum ratio 50) in the polygonal rotating barrel, and vacuum the barrel until the pressure reaches 9.9x10 -4 Below Pa;

[0074] Ar gas (volume purity above 99.9%) is introduced into the barrel, the flow rate is 15ml / min, and the pressure in the barrel is maintained at 2.0Pa;

[0075] The rotating speed of the polygonal drum is increased to 10 rpm, and the vibration rate outside the barrel is kept at 20 times / min, so that the nano-metal iron particles produced by the bombardment of the copper target by Ar ions are evenly deposited on the surface of the carrier;

[0076] After the spu...

Embodiment 2

[0084] sp-Fe / SiO 2 The catalyst preparation process is as follows:

[0085] The catalyst was prepared by a multi-angle drum sputtering device. Before preparation, the surface of the target was cleaned and treated, and the iron target (mass purity above 99.9%) was bombarded with Ar ions generated by a plasma generator for 20 minutes;

[0086] The carrier powder silica (specific surface area about 200m 2 / g) As for the multi-angle rotating barrel, vacuum the barrel until the pressure reaches 9.9x10 -4 Below Pa;

[0087] Ar gas (volume purity above 99.9%) is introduced into the barrel, the flow rate is 30ml / min, and the pressure in the barrel is maintained at 1.0Pa;

[0088] The rotating speed of the polygonal drum is increased to 20 rpm, and the vibration rate outside the barrel is kept at 30 times / min, so that the nano-metal iron particles produced by the bombardment of the copper target by Ar ions are evenly deposited on the surface of the carrier;

[0089] After the sputt...

Embodiment 3

[0094] The silica carrier (specific surface area of about 200m 2 / g) is replaced with carbon nanotubes (CNT, multi-walled, with a specific surface area of about 400m 2 / g), the rest of the preparation process is the same as above, and the catalyst is denoted as sp-Fe / CNT.

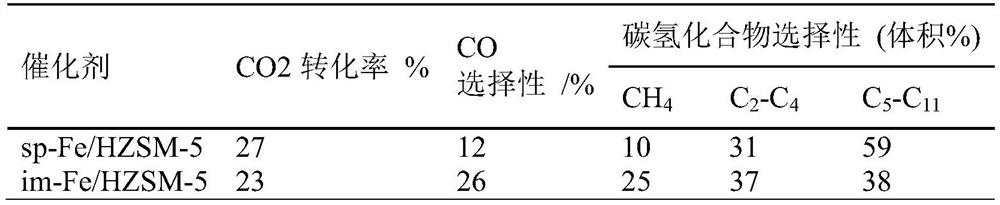

[0095] The carbon dioxide reaction results of the iron catalyst prepared in Table 3 compared with the traditional catalyst

[0096]

[0097]The evaluation experiment of carbon dioxide hydrogenation reaction shows that, compared with the im-Fe / CNT catalyst prepared by the traditional impregnation method, the sp-Fe / CNT iron catalyst prepared by the magnetron sputtering method has a higher carbon dioxide reaction rate in the carbon dioxide reaction. 2 -C 4 The selectivity of olefins and alkanes in the distillation section is significantly improved, and the proportion of olefins can be increased to 75% in C2-C4. The conversion of carbon dioxide is also increased, while the selectivity to the by-produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com