Domestic garbage treatment method and its realization device

A technology of domestic waste and treatment method, which is applied in the field of domestic waste regeneration and treatment, can solve the problems of secondary pollution, complicated treatment process, high investment cost, etc., and achieve the effect of not easy to raise dust, complete combustion and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The domestic waste treatment method is to divide the domestic waste into organic waste and inorganic waste, and the organic waste is reserved; 100kg of organic waste is squeezed and crushed repeatedly, so that the diameter of the organic waste is 10mm; and then divided into waste water and water content of 40% by pressing The solid waste, solid waste and waste water are all for use; the solid waste is dried to make the water content 8%; the solid organic matter is crushed into debris with a diameter of 0.5mm; the debris is made into a diameter of 6mm and a length of 10mm. Combustible wood pellets; pressurized and atomized waste water can be used as fuel for drying solid waste, and can also be used for other equipment that requires fuel.

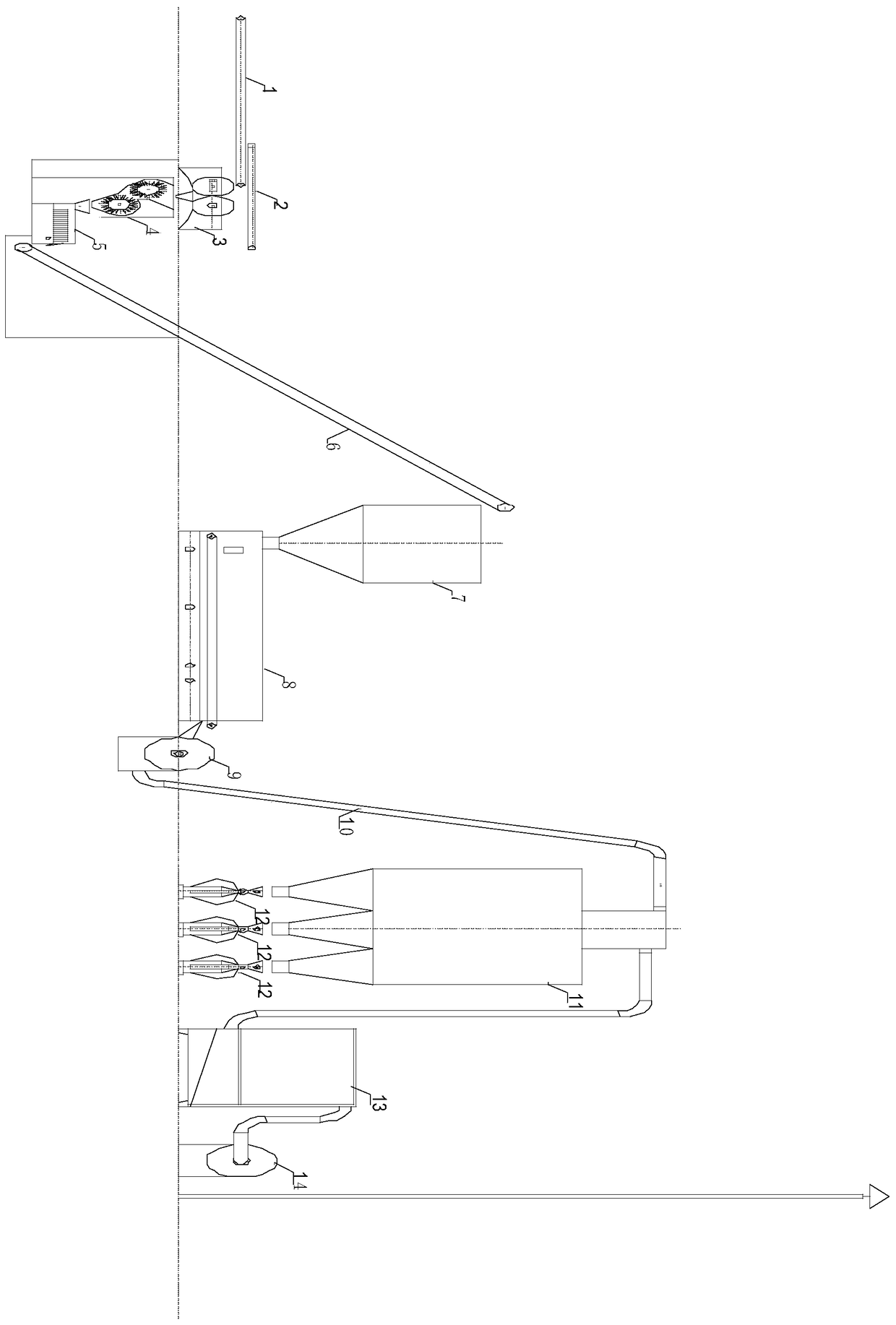

[0037] like figure 1 As shown, the implementation device of the domestic waste treatment method includes a sorting conveyor 1, a sorting machine 2, a rolling mill 3, a shredder 4, a squeezer 5, a belt conveyor 6, a storage warehouse 7,...

Embodiment 2

[0041] 100kg of organic waste is squeezed and crushed repeatedly to make the diameter of the organic waste 13mm; then it is divided into waste water and solid waste with a water content of 43% by pressing, and both the solid waste and waste water are used for later use; 10%; crush the solid organic matter into debris with a diameter of 1mm; make the debris into combustible wood pellets with a diameter of 8mm and a length of 18mm.

Embodiment 3

[0043] 100kg of organic waste is repeatedly squeezed and crushed so that the diameter of the organic waste is 15mm; then it is divided into waste water and solid waste with a water content of 45% by pressing, and both the solid waste and waste water are used for later use; 15%; crush the solid organic matter into chips with a diameter of 1.5 mm; make the chips into combustible wood pellets with a diameter of 10 mm and a length of 25 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com