Synthesis method for gamma-polyglutamic acid flocculant modified through Mannich reaction and application of gamma-polyglutamic acid flocculant

A Mannich reaction, polyglutamic acid technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc., can solve secondary pollution, difficult to treat waste residue, human health and environment hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

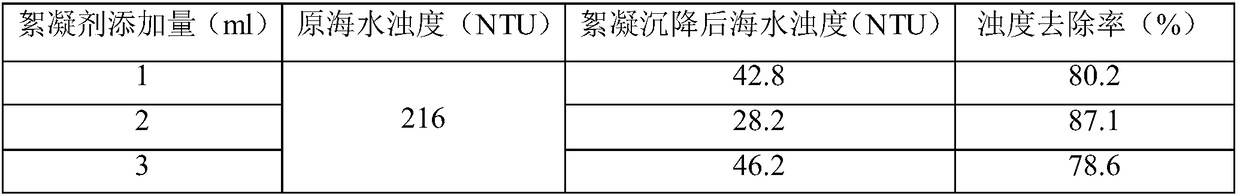

Embodiment 1

[0026] Mannich reaction occurs with gamma-polyglutamic acid, diethanolamine and formaldehyde, and reacts in water phase.

[0027] Synthesis of modified γ-polyglutamic acid flocculant by Mannich reaction

[0028] Weigh 2g of γ-polyglutamic acid (molecular weight is about 300,000)

[0029] Add 20ml of deionized water into a 150ml round bottom flask and stir evenly.

[0030] Weigh 0.08 mol (8.41 g) of diethanolamine (mass fraction ≥ 99%) and place it in a test tube for use.

[0031] Weigh 0.1 mol of formaldehyde solution (37% aqueous solution) (8.11 g) and place it in a test tube for use.

[0032] Place the round-bottomed flask containing the γ-polyglutamic acid solution in a heat-collecting constant temperature heating magnetic stirrer, add the diethanolamine to be used, heat and stir until the temperature rises to 70°C, add formaldehyde solution dropwise, and react 4 hours, a mixture was obtained. After the reaction, the mixed solution was placed in a 250ml beaker and natur...

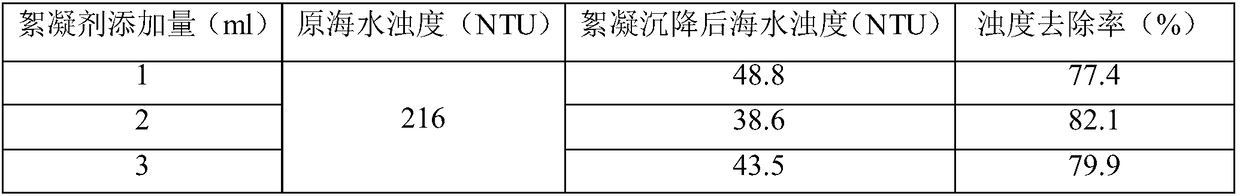

Embodiment 2

[0038] Mannich reaction occurs with gamma-polyglutamic acid, diethanolamine and formaldehyde, and reacts in water phase.

[0039] Synthesis of modified γ-polyglutamic acid flocculant by Mannich reaction

[0040] Weigh 2g of γ-polyglutamic acid and add 20ml of deionized water into a 150ml round bottom flask, and stir evenly.

[0041] Weigh 0.08 mol (8.41 g) of diethanolamine (mass fraction ≥ 99%) and place it in a test tube for use.

[0042] Weigh 0.1 mol (8.11 g) of formaldehyde solution (37% aqueous solution) and place it in a test tube for use.

[0043] Place the round-bottomed flask containing the γ-polyglutamic acid solution in a heat-collecting constant temperature heating magnetic stirrer, add the diethanolamine to be used, heat and stir until the temperature rises to 60°C, add formaldehyde solution dropwise, and react 3 hours, a mixture was obtained. After the reaction, the mixed solution was placed in a 250ml beaker and naturally cooled to room temperature, and 5 ti...

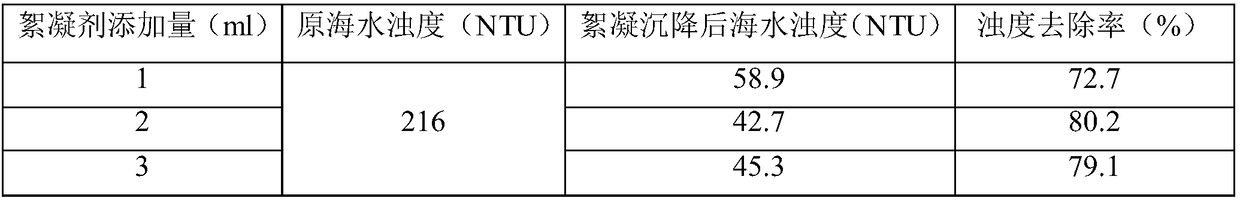

Embodiment 3

[0049] Mannich reaction occurs with gamma-polyglutamic acid, diethanolamine and formaldehyde, and reacts in water phase.

[0050] Synthesis of modified γ-polyglutamic acid flocculant by Mannich reaction

[0051] Weigh 2g of γ-polyglutamic acid and add 20ml of deionized water into a 150ml round bottom flask, and stir evenly.

[0052] Weigh 0.08 mol (8.41 g) of diethanolamine (mass fraction ≥ 99%) and place it in a test tube for use.

[0053] Weigh 0.04mol (3.28g) of formaldehyde solution (37% aqueous solution) and place it in a test tube for use.

[0054] Place the round-bottomed flask containing the γ-polyglutamic acid solution in a heat-collecting constant temperature heating magnetic stirrer, add the diethanolamine to be used, heat and stir until the temperature rises to 60°C, add formaldehyde solution dropwise, and react 3 hours, a mixture was obtained. After the reaction, the mixed solution was placed in a 250ml beaker and naturally cooled to room temperature, and 5 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com