Benzene refining desulfurization adsorbent and preparation method thereof

A technology of adsorbent and reducing agent, applied in the field of benzene refining desulfurization adsorbent and its preparation, can solve the problems of high cost and unsuitable for large-scale use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

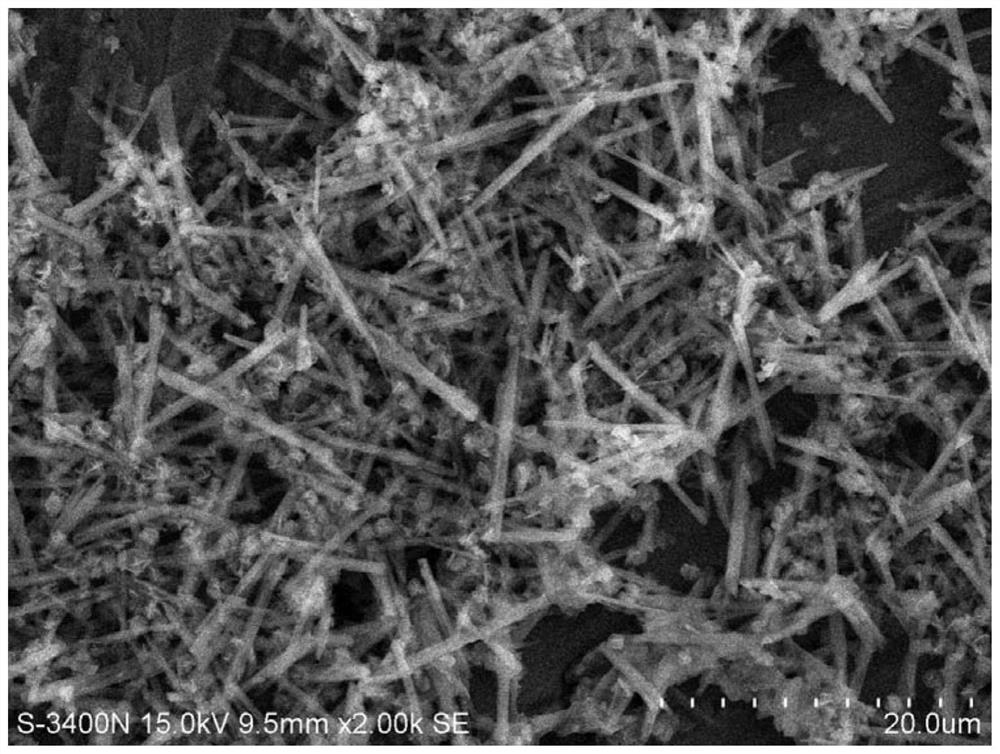

[0042] Preparation of needle-like alumina carrier with mesoporous structure and preparation of adsorbent

[0043] 1. Preparation of needle-shaped alumina carrier with mesoporous structure

[0044] Place 5 mol octadecanthaneal aluminum sulfate Al 2 (SO 4 ) 3 .18H 2 O dissolved in 1000mL deionized water and then transferred to a 5000mL PTFE container. Then add 3750 mL of aqueous ammonia solution with a concentration of 8 mol / L to the above solution, in an airtight container. At 140 °C at 340 rpm, pellet for 6 h. Finally, the filtration product was washed with deionized water to pH = 7, the resulting filter cake was dried in a vacuum at 70 °C for 10 h, the dried product was crushed and molded into about 2 mm particles, dried at 150 °C for 4 hours, and calcined at 570 °C for 6 h to obtain an alumina carrier. The ammonia precipitant with Al 3+ The molar ratio is 6:1, and the length of the needle-shaped alumina carrier is about 18um.

[0045] 2. Preparation of adsorbent

[0046] The pre...

Embodiment 2

[0049] Preparation of needle-like alumina carrier with mesoporous structure and preparation of adsorbent

[0050] 1. Preparation of needle-shaped alumina carrier with mesoporous structure

[0051] 5 mol aluminum nitrate (Al(NO 3 ) 3 ·9H 2 O) Dissolve in 1000mL deionized water and then transfer to a 5000mL PTFE container. Then add 6000 mL of urea solution at a concentration of 5 mol / L to the above solution in an airtight container. At 150 °C at 300 rpm, pellet for 7 h. Finally, the filter product was washed with deionized water to pH = 7, the resulting filter cake was dried in vacuo at 80 °C for 12 h, the dried product was crushed and molded into about 2mm particles, dried at 160 °C for 3 hours, and roasted at 550 °C for 4h to obtain an alumina carrier. The urea precipitant with Al 3+ The molar ratio is 6:1, and the needle-shaped alumina carrier length is about 20um.

[0052] 2. Preparation of adsorbent

[0053] The precursor chloroplatinic acid (H. 20.1) with a platinum mass conte...

Embodiment 3

[0056]Preparation of needle-like alumina carrier with mesoporous structure and preparation of adsorbent

[0057] 1. Preparation of needle-shaped alumina carrier with mesoporous structure

[0058] 4mol aluminum hexahydrate (AlCl 3 ·6H 2 O) Dissolve in 1000mL deionized water and then transfer to a 5000mL PTFE container. Then add 3000 mL sodium hydroxide solution at a concentration of 6 mol / L to the above solution in an airtight container. At 160 °C at 320 rpm, pellet for 7 h. Finally, the filter product was washed with deionized water to pH = 7, the resulting filter cake was dried in vacuo at 80 °C for 12 h, the dried product was crushed and molded into about 2 mm particles, dried at 130 °C for 5 hours, and roasted at 530 °C for 7 h to obtain an alumina carrier. The sodium hydroxide precipitant with Al 3+ The molar ratio is 4.5:1, and the needle-like alumina carrier length is about 22um.

[0059] 2. Preparation of adsorbent

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com