Antibacterial nano-silver/lignin polyurethane dressing and one-step method for preparing dressing

A technology of lignin and nano-silver, applied in the field of biomedical materials, can solve the problems of complexity and large amount of antibacterial agent added, and achieve the effect of improving antibacterial effect, reducing toxic damage and reducing Ag content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the parts by weight, weigh 30 parts of enzymatic lignin, 80 parts by weight of polyethylene glycol 400, 20 parts by weight of glycerin, and 4.5 parts of 98% sulfuric acid in a three-necked flask, mechanically stir and heat at 140°C under nitrogen protection After reacting for 1 hour, the lignin polyol was obtained by removing water, which was set aside.

[0033] According to parts by weight, take 20 parts of lignin polyols prepared above, 0.2 parts of dibutyltin dilaurate, 0.06 parts of silver nitrate aqueous solution with a concentration of 0.1mol / L as foaming agent, after stirring and mixing at 800r / min for 7min, Add 13.5 parts of hexamethylene diisocyanate and stir and mix at 12000r / min for 60s, and pour it into the mold quickly, leave it to foam at room temperature, ripen and release the mold, and obtain the antibacterial nano silver / lignin polyurethane dressing (marked as dressing 1).

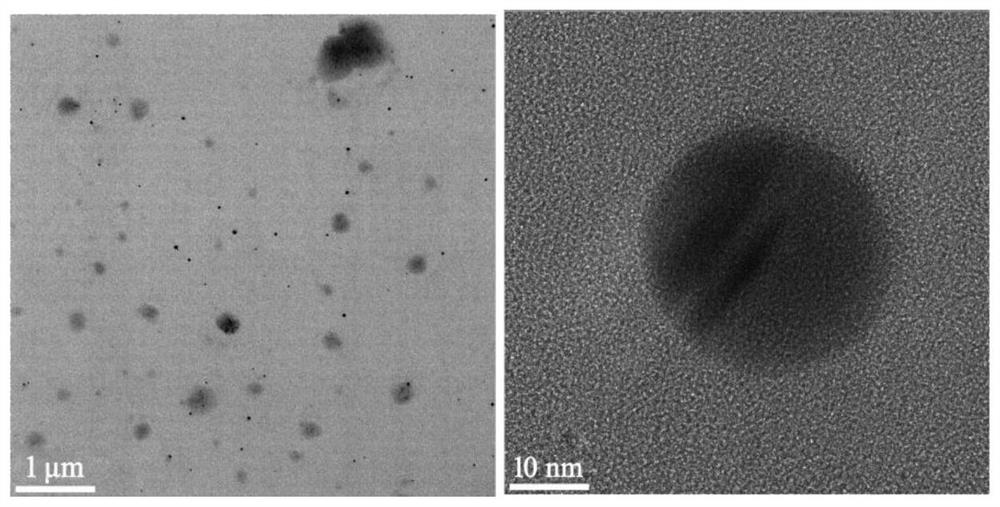

[0034] The transmission electron microscope figure of the nanomet...

Embodiment 2

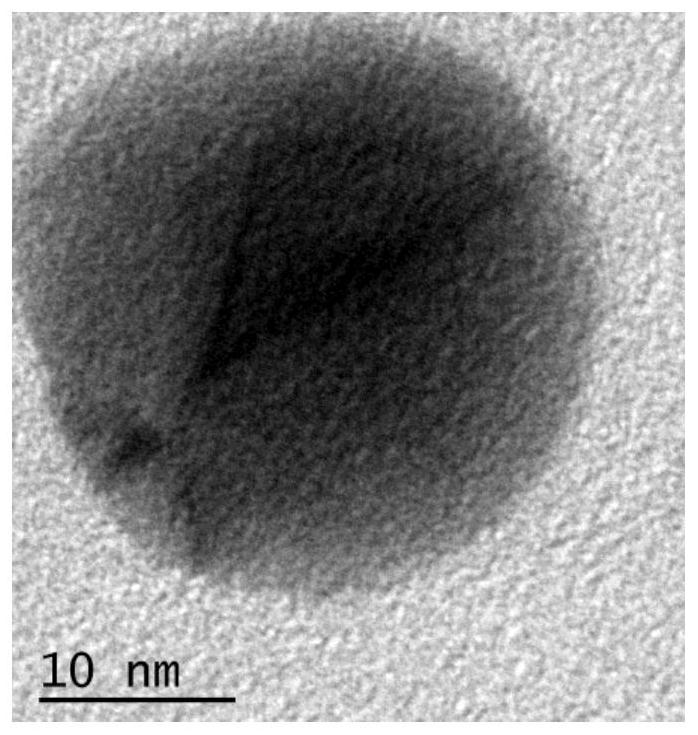

[0038] The difference with Example 1 is only that, this embodiment replaces 0.1mol / L silver nitrate aqueous solution with 1mol / L silver nitrate aqueous solution, obtains antibacterial nano-silver / lignin polyurethane dressing (marked as dressing 2), and this embodiment makes The transmission electron microscope image of the nano silver / lignin polyurethane dressing is shown in figure 2 As shown, the loading of nano-silver accounted for 0.01% of polyurethane.

[0039] The antibacterial nano-silver / lignin polyurethane dressing (marked as dressing 2) made in this embodiment is found through the same method test antibacterial performance as in Example 1, the bacteriostatic effect to Escherichia coli is as follows figure 2 As shown in Dressing 2, the bacteriostatic rate of Escherichia coli in Dressing 2 reached 98.6%, 99.7%, 100%, 100% in 1 hour, 2 hours, 4 hours and 8 hours; the bacteriostatic effect on Staphylococcus aureus Such as image 3 As shown in Dressing 2, the bacterios...

Embodiment 3

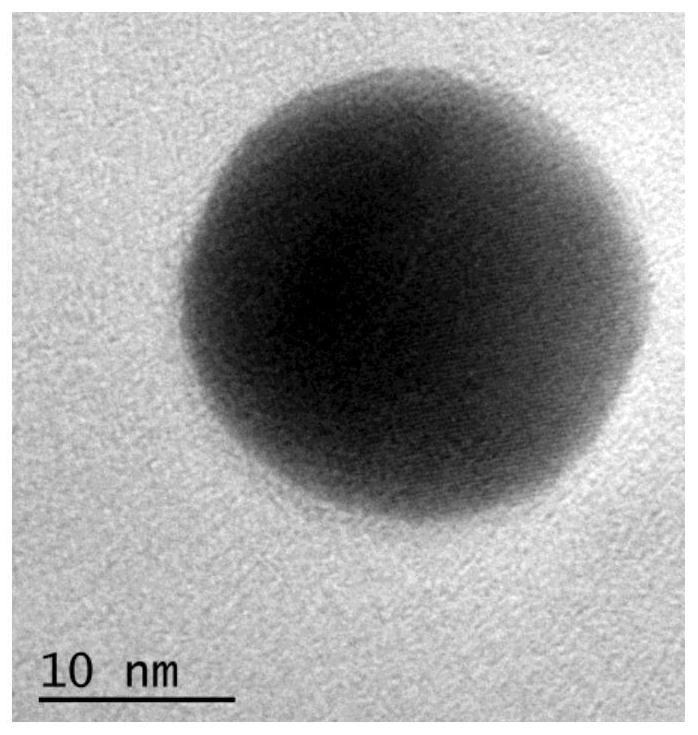

[0041] The difference with Example 1 is only that, this embodiment replaces 0.1mol / L silver nitrate aqueous solution with 7.5mol / L silver nitrate aqueous solution, obtains antibacterial nano-silver / lignin polyurethane dressing (marked as dressing 3), this embodiment makes The transmission electron microscope picture of the obtained nanometer silver / lignin polyurethane dressing is as follows image 3 As shown, the loading of nano-silver accounted for 0.09% of polyurethane.

[0042] The antibacterial nano-silver / lignin polyurethane dressing (marked as dressing 3) made in this embodiment is found through the same method test antibacterial performance as in Example 1, and the bacteriostatic effect of this auxiliary material 3 to Escherichia coli is as follows: figure 2 As shown in dressing 3, the antibacterial rate of auxiliary material 3 to Escherichia coli reached 99.8%, 100%, 100%, and 100% in 1 hour, 2 hours, 4 hours and 8 hours; the antibacterial effect on Staphylococcus aur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com