Method for preparing reinforced biaxially textured Ag based compound substrate

A composite baseband and texture technology, which is applied in other manufacturing equipment/tools, manufacturing tools, cable/conductor manufacturing, etc., can solve the problem of no biaxial texture on the surface of the baseband, achieve enhanced mechanical properties, reduce Ag content, The effect of strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

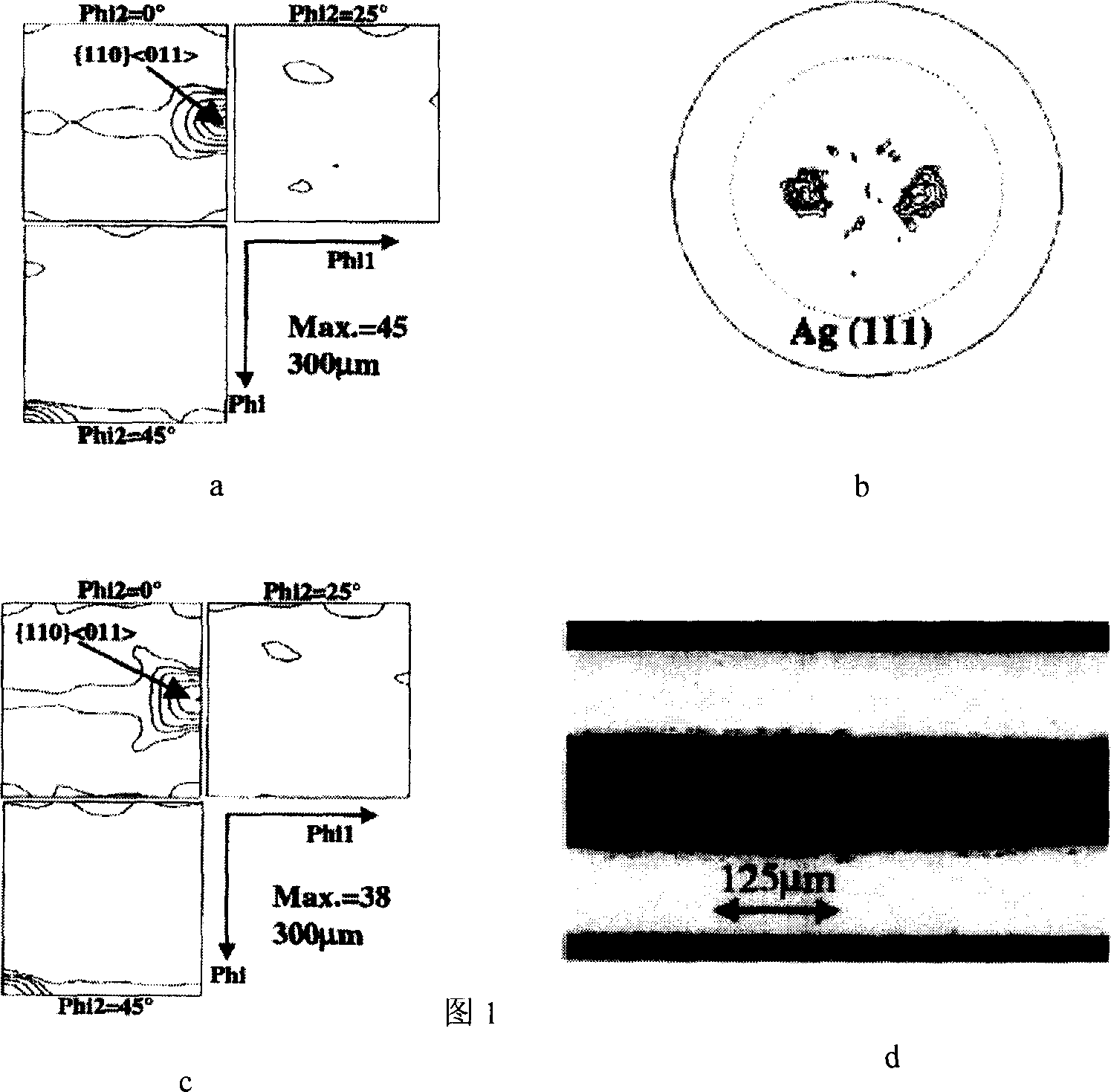

[0018] Example 1. Ni ingot with a purity of 99.99wt%, a 2.5cm thick Ag foil with a purity of 99.95wt%, a 50μm thick Cu foil with a purity of 99.99wt%, in the order of Ag-Cu-Ni-Cu-Ag Arrange and cold-press to obtain a 6mm multilayer ingot; vacuum-anneal the multilayer ingot at 750°C for 6 hours; then cold-roll, the secondary deformation is 10-15%, and the total deformation is greater than 95% to obtain a thickness of 300μm Baseband. The base tape was then vacuum annealed at 800°C for 3 hours. The surface silver texture {110} is formed, see Figure 1. In Figure 1a, 1 =90°, ф=45°, 2 The intensity distribution area of =0° indicates the {110} texture, the ODF value reaches 45, and the composition is single, and the pole figure FWHM of the (111) plane is 15° (Figure 1b). The final base tape obtained was annealed at 900°C to test the stability of the gas texture. The results show that the texture of the baseband has good stability, and the ODF value of the {110} orientation after an...

Embodiment 2

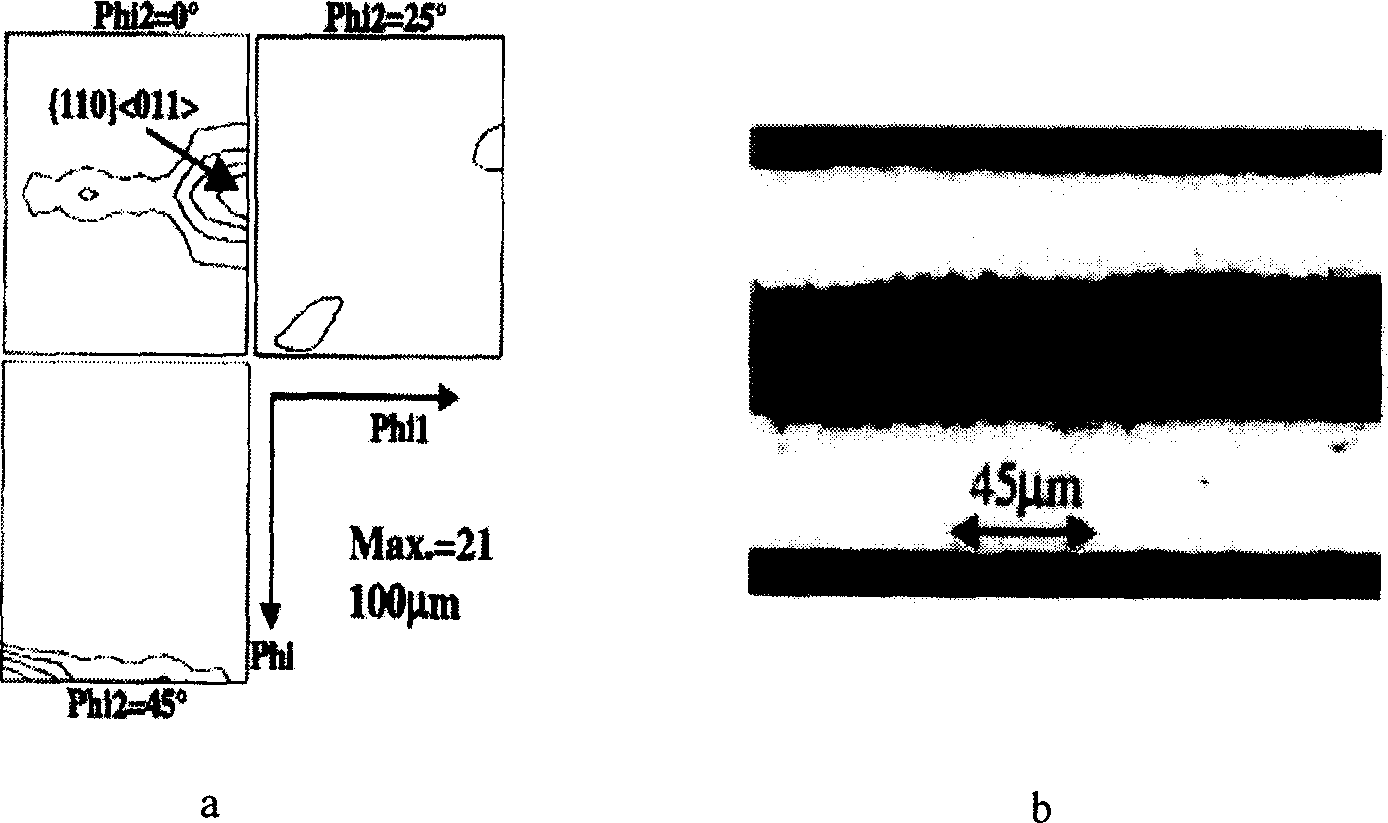

[0019] Example 2. Ni ingot with 99.99wt% purity, 1cm thick Ag foil with 99.95wt% purity, 40μm thick Cu foil with 99.99wt% purity, arranged in the order of Ag-Cu-Ni-Cu-Ag After cold pressing, a 3mm multi-layer ingot is obtained; the multi-layer ingot is vacuum annealed at 800°C for 5 hours; and then cold-rolled, the secondary deformation is 10-15%, and the total deformation is greater than 95% to obtain a thickness of 100μm Baseband. The base tape was then vacuum annealed at 800°C for 4 hours. Formed surface silver texture {110}, see figure 2 , And the composition is single; the composite baseband has a good combination.

Embodiment 3

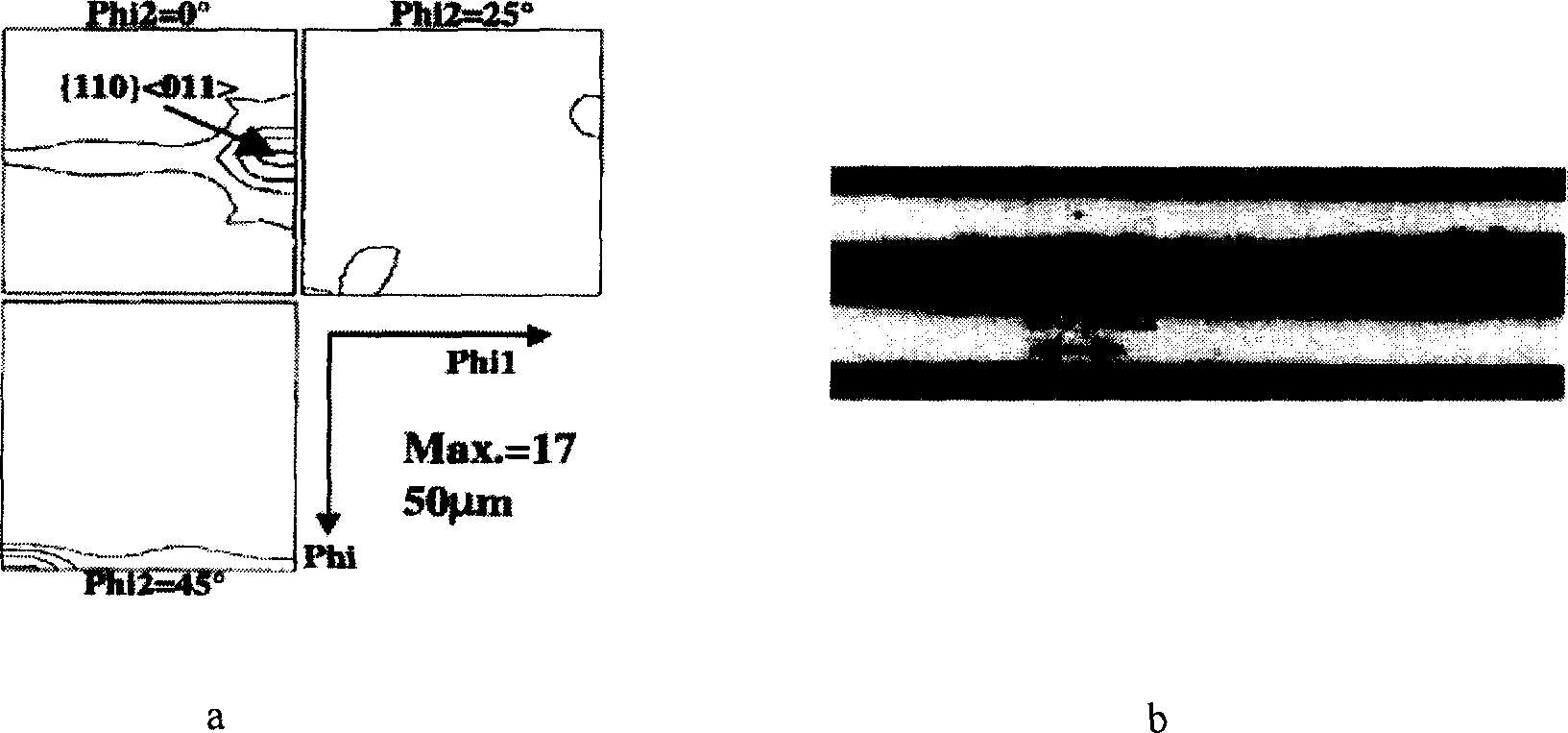

[0020] Example 3. Ni ingots with a purity of 99.99wt%, Ag foils with a thickness of 3.5cm 99.95wt%, and Cu foils with a thickness of 100μm with a purity of 99.99wt% were arranged in the order of Ag-Cu-Ni-Cu-Ag, A 8mm multilayer ingot is obtained by cold pressing; the multilayer ingot is vacuum-annealed at 800℃ for 6 hours; and then cold rolled, the secondary deformation is 10-15%, and the total deformation is greater than 95% to obtain a base tape with a thickness of 50μm . Then the base tape was vacuum annealed at 900°C for 6 hours. Formed surface silver texture {110}, see image 3 , And the composition is single; the composite baseband has a good combination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com