Lithium battery processing device and processing method thereof

A technology of processing device and processing method, which is applied in the direction of lithium battery, device for coating liquid on the surface, battery pack parts, etc. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

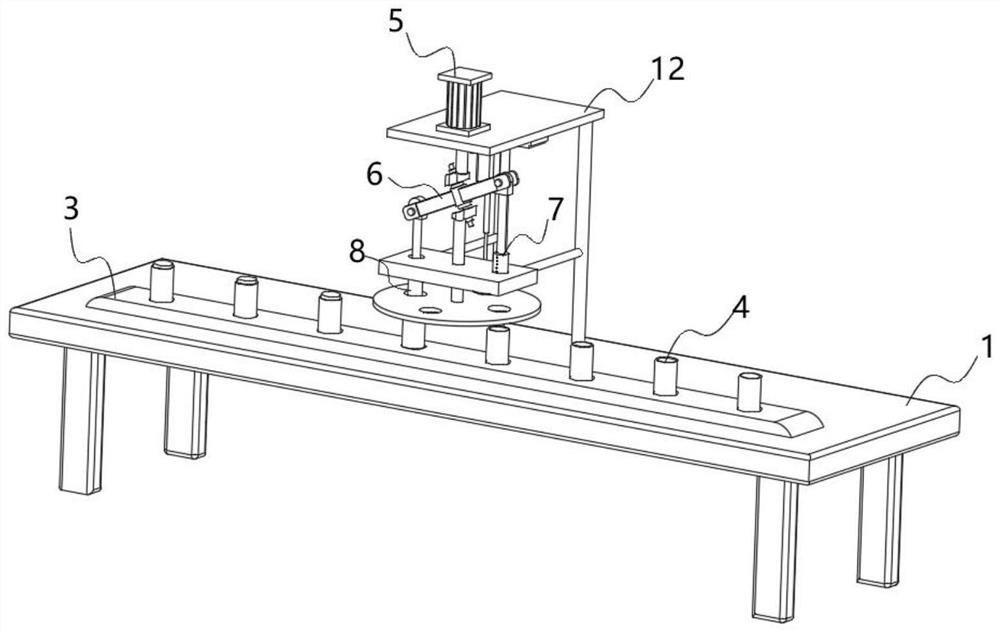

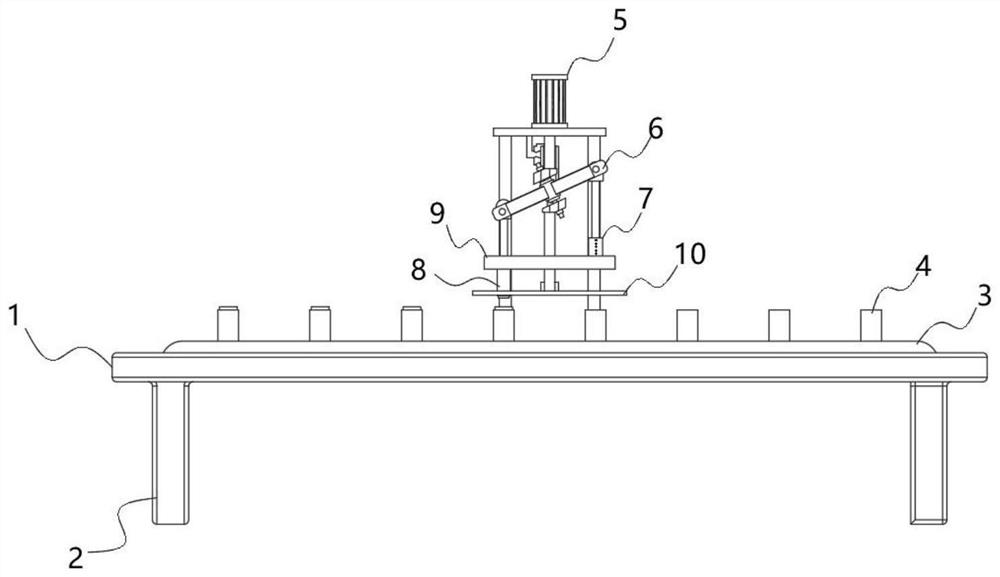

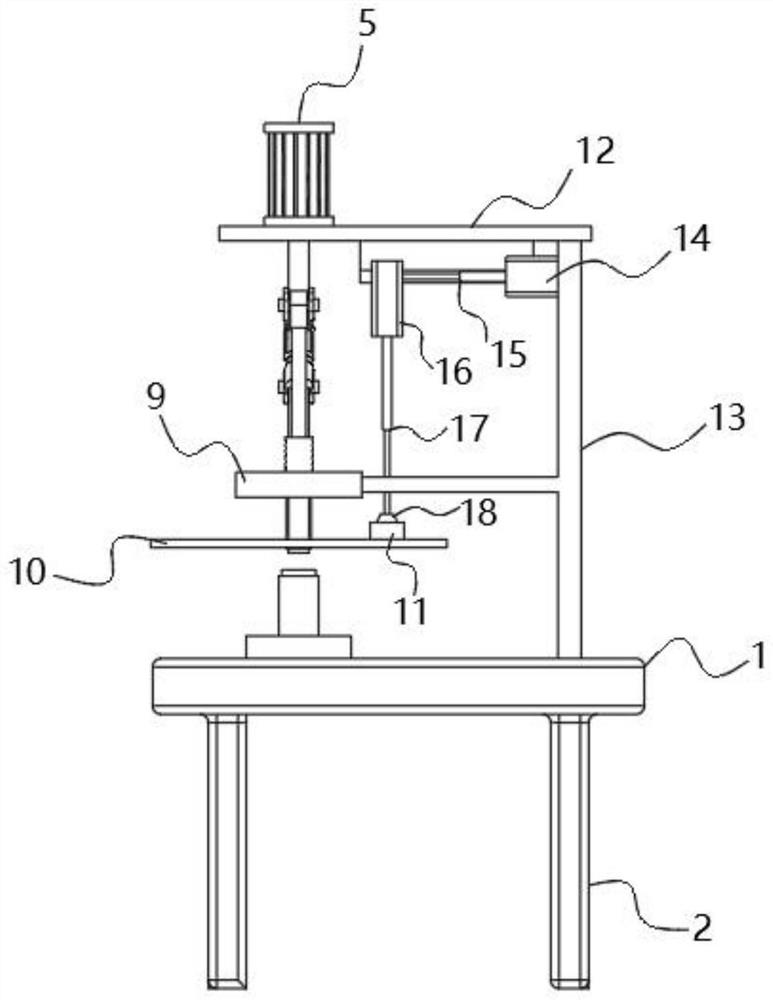

[0041] Attached below Figure 1-7 The present invention is further described with embodiment:

[0042] A lithium battery processing device, comprising: a conveying mechanism 3, the conveying mechanism 3 is at least used to convey the battery case 4;

[0043] The first driving member 5 is connected with the swing arm 6, and the swing arm 6 is respectively used to drive the gluing mechanism 7 and the pressing mechanism 8, and the gluing mechanism 7 can at least push toward the battery case The inner wall of the body 4 is coated with glue, and a conveying mechanism 10 is arranged between the conveying mechanism 3 and the first driving member 5. The conveying mechanism 10 is at least used to convey the cover 11. When the cover 11 is in the pressing position When the mechanism 8 presses the working area, the pressing mechanism 8 presses the cover body 11 to make the cover body 11 cooperate with the battery case 4 .

[0044] In this embodiment, the first driving member 5 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com