Intelligent cutter handle auxiliary milling cutter life prediction method based on GRU neural network

A neural network and milling tool technology, applied in the field of intelligent tool holder-assisted milling tool life prediction, can solve problems such as inability to track tool wear and service life, complex relationship between tool wear, etc. The effect of good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings.

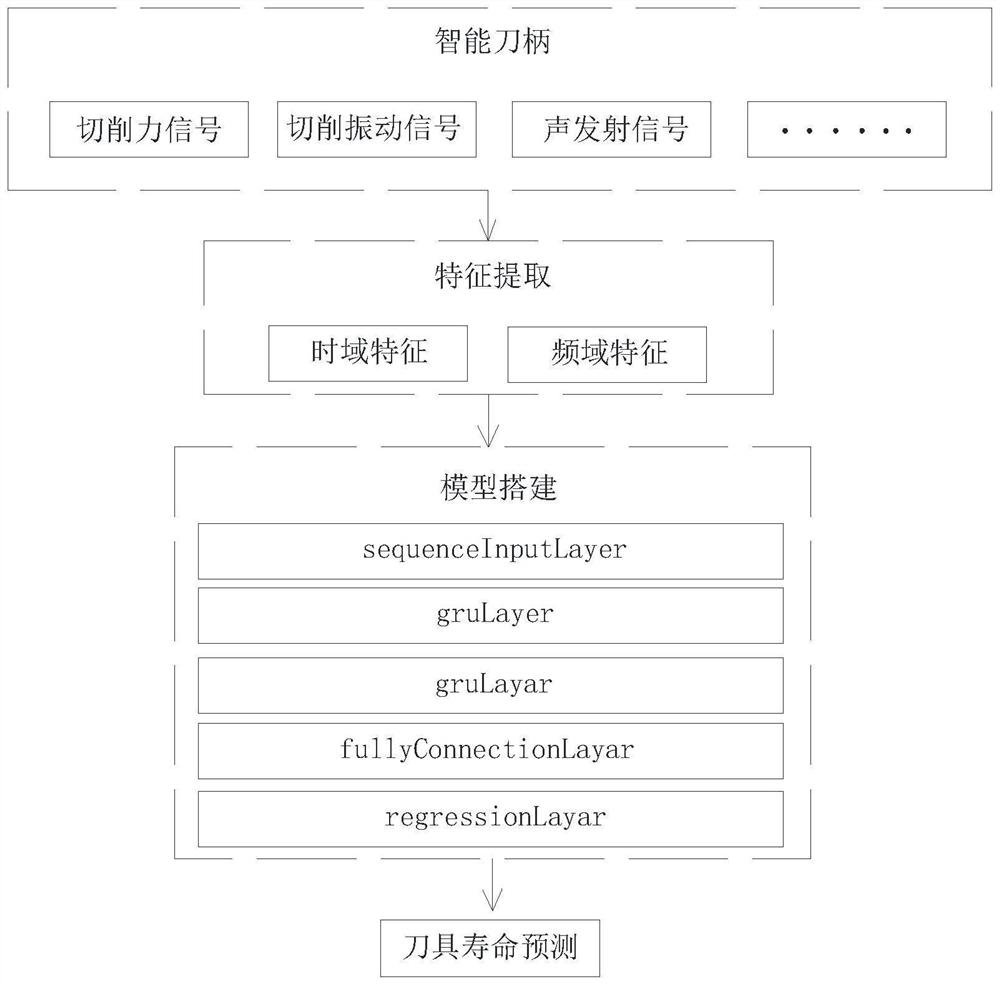

[0047] For specific implementation: see figure 1 ,

[0048] The intelligent tool holder-assisted milling tool life prediction method based on GRU neural network includes the following steps,

[0049] 1) Obtain the state monitoring signal of the tool, and perform data preprocessing on the state monitoring signal to obtain the data sample set of the tool.

[0050] The acquisition of the data sample set of the cutting tool includes the following steps,

[0051] 1) Obtain several state monitoring signals of the tool X, Y, and Z axes through the intelligent tool handle;

[0052] 2) Carry out data preprocessing to the state monitoring signal, and extract the time domain feature and frequency domain feature of the state monitoring signal;

[0053]3) The life cycle of the tool is continuously and evenly divided into T samples, wherein one pass of the tool is take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com