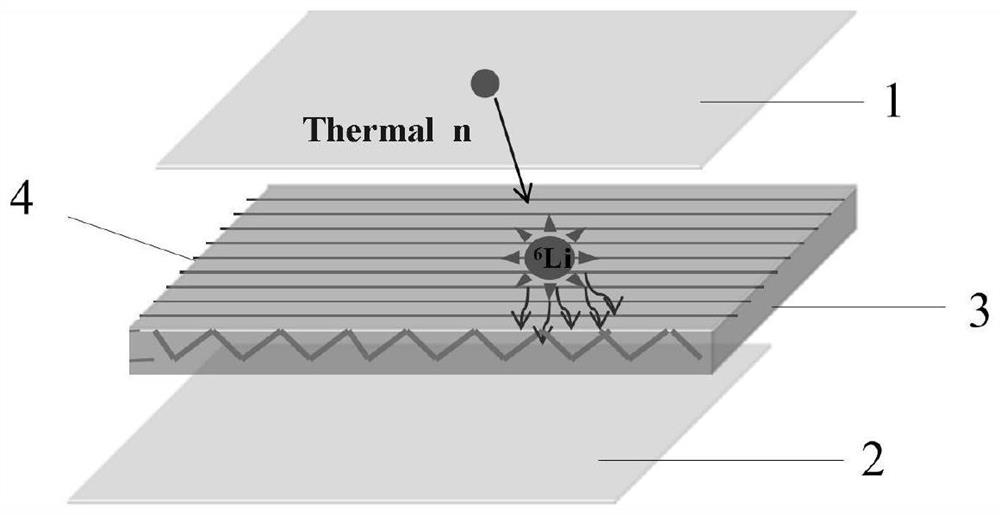

Novel large-area thermal neutron detector

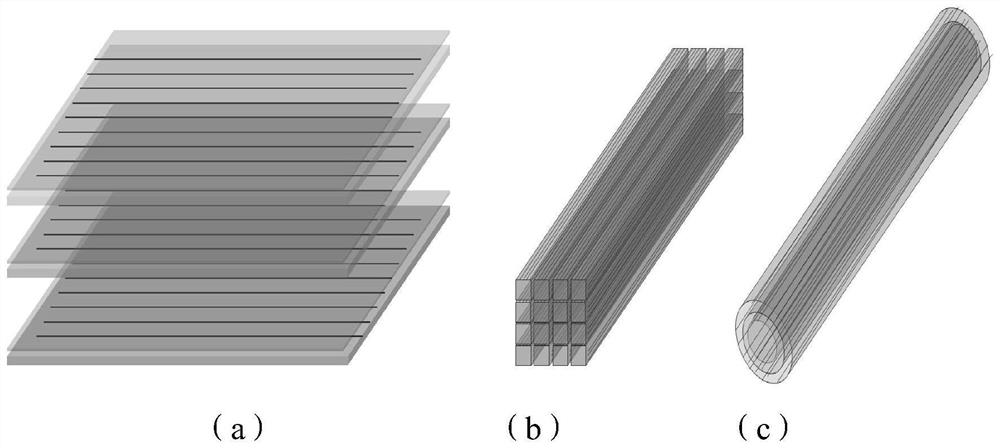

A thermal neutron and detector technology, applied in the field of new large-area thermal neutron detectors, can solve the problems of low fluorescence output, high sensitivity of high-energy gamma, and difficult process technology, and achieve the effect of increasing the sensitive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

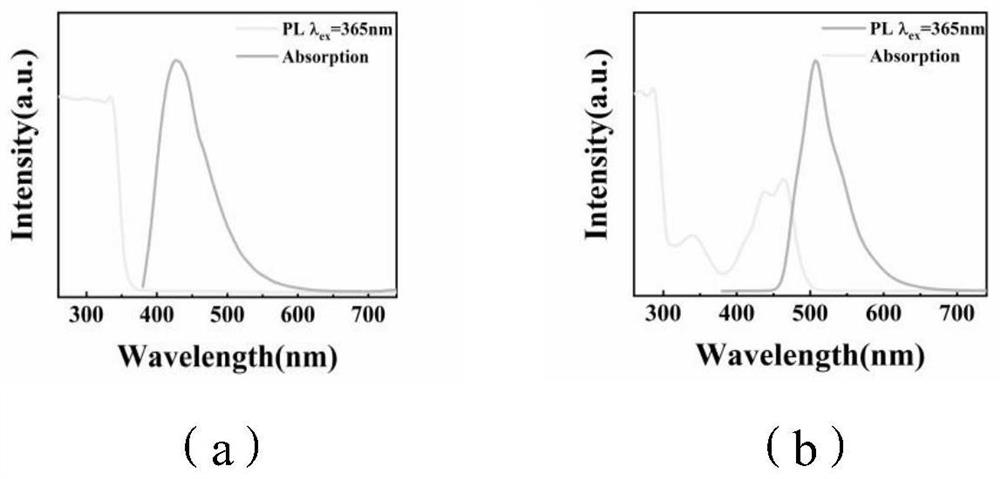

[0023] About the development of high performance and large size lithium glass in China 3 The research of He tube instead of detector started late, and at present, they all focus on the preparation of lithium glass material and the development of lithium glass detector with small sensitive area. Some studies have published that 20 ~ 50μ m lithium glass fiber (bare wire) is prepared by crucible drawing method, and the detector is made by integrally pouring multiple layers of lithium glass fiber (2 ~ 5mm) with glass light guide. However, due to the rapid attenuation of lithium glass fiber (bare wire) in the light guide, the length of the detector is not more than 10cm, and the fiber arrangement is relatively large. Foreign research has successfully developed two kinds of lithium glass-based 3 He tube replaces large-area neutron detector: one is φ 120μ m developed by Nucsafe Company in the United States. 6 Li glass fiber, with high transparency and good toughness, can exceed 2m in len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com