Lateral injection device for strengthening water jet at space-limited part

A spraying device and water jet technology, which is applied in the field of surface strengthening, can solve the problems of surface cutting of workpieces, failure to ensure that the straight nozzle is perpendicular to the processed surface, and inability to realize water jet strengthening in space-limited parts, so as to increase particle jet flow speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

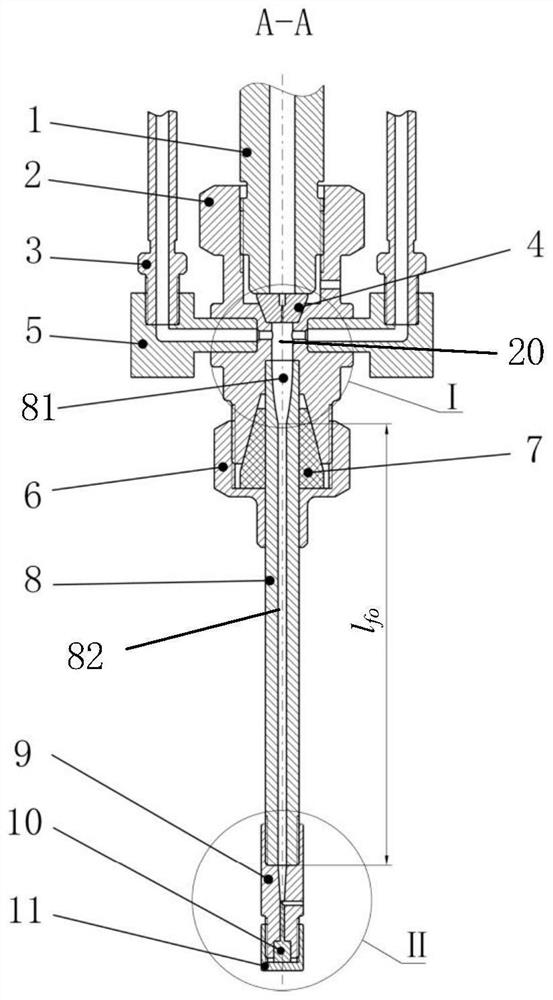

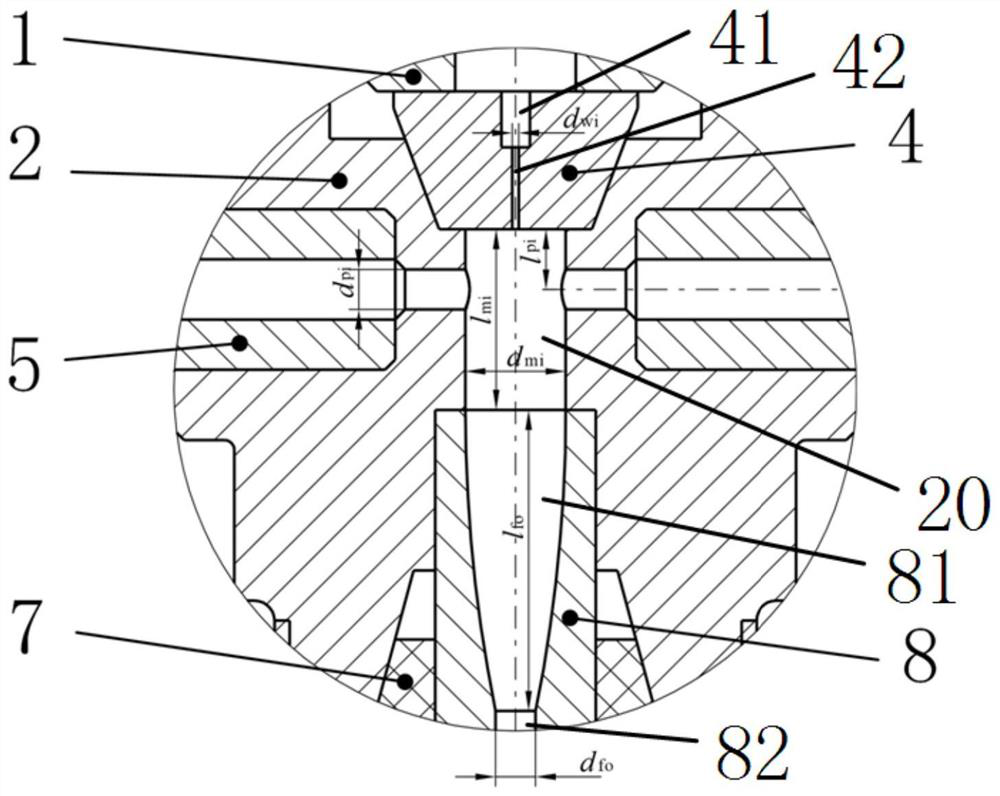

[0031] Below in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail.

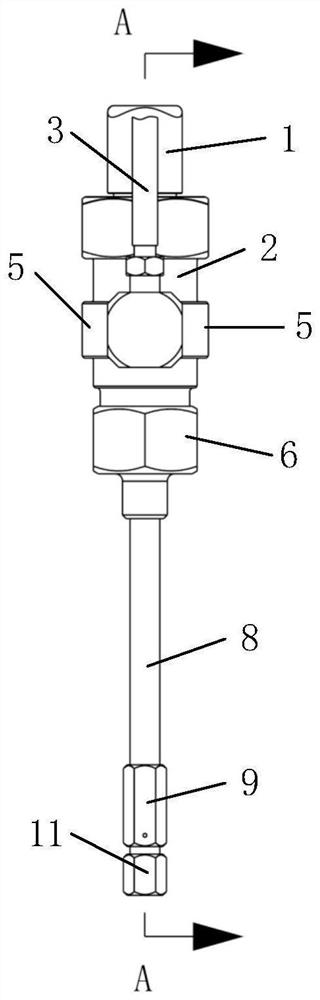

[0032] like figure 1 and 2 As shown, the embodiment of the present invention provides a lateral injection device for water jet enhancement in space-restricted areas, including a communication valve 2, in which an inlet pipe 1, a nozzle 4 and a focus pipe are arranged in sequence along the axial direction. 8. The inlet pipe 1 is threadedly connected to the upper end of the communication valve 2 and the nozzle 4 is pressed into the communication valve 2. The focusing tube 8 is connected to the lower end of the communication valve 2, wherein a lock is provided between the focusing tube 8 and the communication valve 2. Tighten the sleeve 7, and then set it on the outside of the focusing tube 8 and the communication valve 2 through the upper threaded pressure cap 6, so that the two are fastened; a mixing chamber 20 is formed between the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com