Thick double-grain-line rubber plate production process based on physical repair method

A production process and physical technology, applied in the field of coarse double-textured rubber sheet production technology, can solve the problems of high labor intensity, blind areas of foaming, and the surface of the rubber sheet is not flat enough, and achieves the effect of reasonable structural design and improved flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

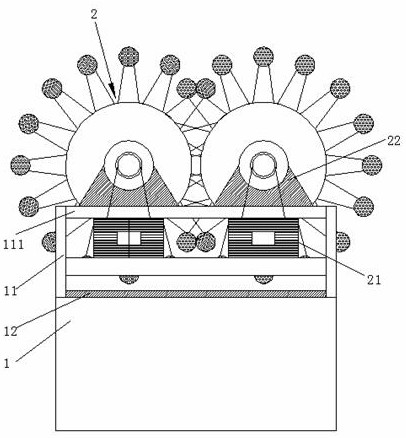

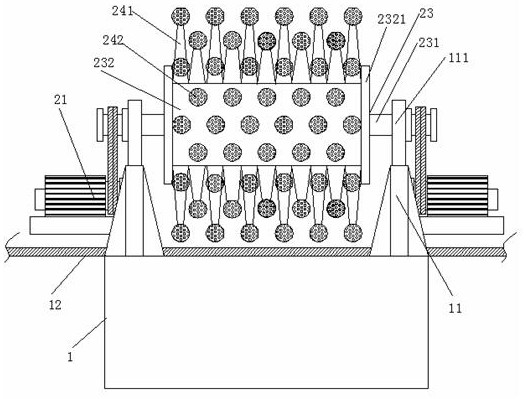

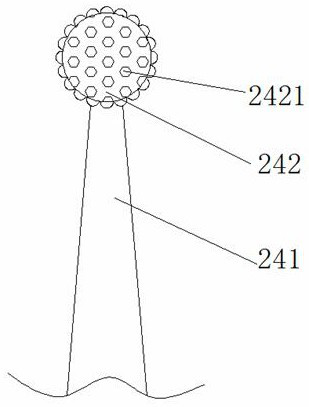

Image

Examples

Embodiment

[0035] Embodiment: the production process of coarse double-cloth rubber sheet based on the physical repair method, the production process of the coarse double-cloth rubber sheet based on the physical repair method, comprises the following steps:

[0036] 1) Raw material pretreatment

[0037] Check the working condition of the special mixer, and after confirming that the working condition is good, clean the mixer and the receiving tray below;

[0038] a. Sulfur pre-dispersion: prepare 160Kg of sulfur and 80Kg of mica powder, put the weighed sulfur and mica powder into the mixer and stir for 30 minutes, and discharge the materials for later use; repeat the above steps until the task is completed, turn off the power of the special mixer, and clean up On-site; the purpose is to improve the dispersion of sulfur and avoid appearance defects caused by sulfur spots on the surface of the product;

[0039] b. Refining and filtering of latex reclaimed rubber:

[0040] Step 1: Check the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com