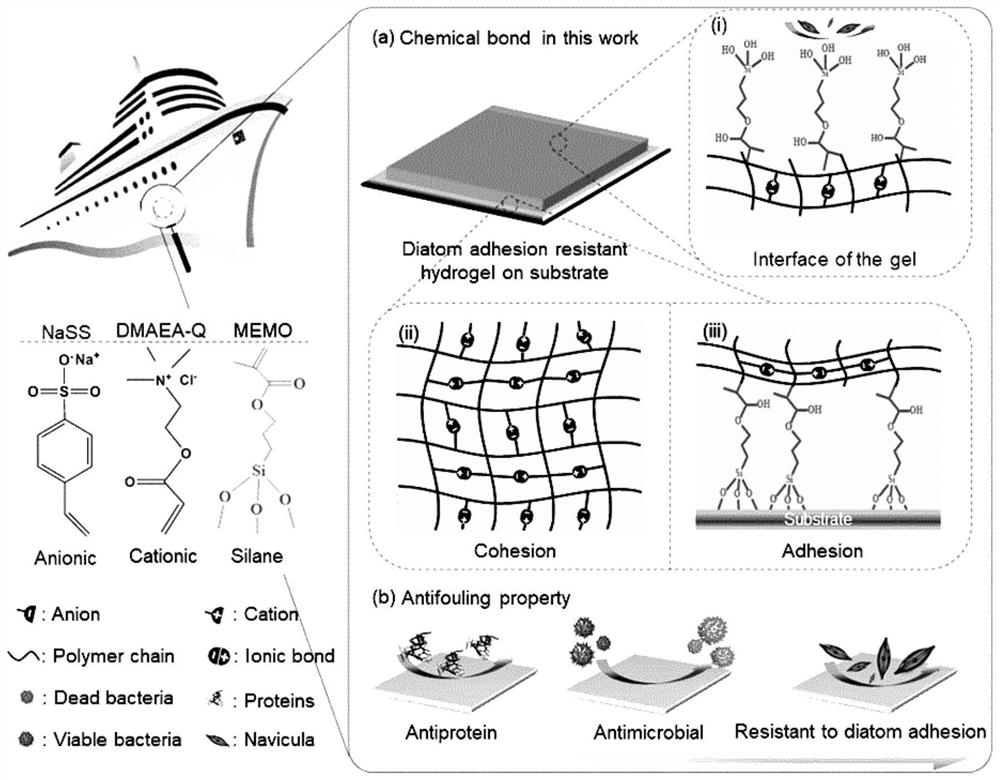

Bacteriostatic and seaweed adhesion-resistant silane modified polyampholyte hydrogel high-adhesion coating and preparation method thereof

A polyampholyte, silane modification technology, applied in coatings, antifouling/underwater coatings, paints containing biocides, etc., can solve the problem of weak adhesion between silane and substrate, non-electrolyte hydrophilic polymers Weak hydration and other problems, to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1): Plasma cleaning the glass substrate washed with deionized water and dried for 10 minutes to obtain a hydroxylated substrate surface.

[0033] Step 2): Measure 80ml of ethanol, 20ml of deionized water, and 0.2ml of acetic acid in a square container, add 2wt% MEMO relative to the mass of the solvent, and mix well.

[0034] Step 3): Put the glass substrate in step 1) into the mixed solution in step 2), dip-coat at room temperature for 2 hours, and then dry at 60° C. for 30 minutes.

[0035] Step 4): The glass substrate obtained in step 3) is combined with untreated glass and a silicone gasket to form a mold, and preheated in an oven at 90° C. for 30 minutes.

[0036] Step 5): Weigh 3.1122g DAC (55mol%), 2.4093g NaSS (45mol%), 0.0039g MBAA (0.1mol%) and 0.0037g KA (0.1mol%) respectively in the beaker, add 10ml deionized water after 70 °C and stirred in a water bath for 15 minutes to obtain a uniform prepolymer solution.

[0037] Step 6): Add 15 μl MEMO to the pre...

Embodiment 2

[0040] Step 1): Plasma cleaning the glass substrate washed with deionized water and dried for 10 minutes to obtain a hydroxylated substrate surface.

[0041] Step 2): Measure 80ml of ethanol, 20ml of deionized water, and 0.2ml of acetic acid in a square container, add 2wt% MEMO and mix well.

[0042] Step 3): Put the glass substrate in step 1) into the mixed solution in step 2), dip-coat at room temperature for 2 hours, and then dry at 60° C. for 30 minutes.

[0043] Step 4): The glass substrate obtained in step 3) is combined with untreated glass and a silicone gasket to form a mold, and preheated in an oven at 90° C. for 30 minutes.

[0044] Step 5): Weigh 2.9055g DAC (51.33mol%), 2.6062g NaSS (48.66mol%), 0.0039g MBAA (0.1mol%) and 0.0037g KA (0.1mol%) in a beaker, add 10ml deionized After water, stir in a water bath at 70°C for 15 minutes to obtain a uniform prepolymer solution.

[0045] Step 6): Add 19 μl MEMO to the prepolymer solution obtained in step 5), mix it unifo...

Embodiment 3

[0048] Step 1): Plasma cleaning the glass substrate washed with deionized water and dried for 10 minutes to obtain a hydroxylated substrate surface.

[0049] Step 2): Measure 80ml of ethanol, 20ml of deionized water, and 0.2ml of acetic acid in a square container, add 2wt% MEMO and mix well.

[0050] Step 3): Put the glass substrate in step 1) into the mixed solution in step 2), dip-coat at room temperature for 2 hours, and then dry at 60° C. for 30 minutes.

[0051] Step 4): The glass substrate obtained in step 3) is combined with untreated glass and a silicone gasket to form a mold, and preheated in an oven at 90° C. for 30 minutes.

[0052] Step 5): Weigh 2.8292g DAC (50mol%), 2.677g NaSS (50mol%), 0.0039g MBAA (0.1mol%) and 0.0037g KA (0.1mol%) respectively in a beaker, add 10ml of deionized water Stir in a water bath at 70°C for 15 minutes to obtain a uniform prepolymer solution.

[0053] Step 6): Add 20 μl MEMO to the prepolymer solution obtained in step 5), mix it eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com