Hydrogen sulfide corrosion resistant rubber composition for oil and gas fields

A rubber composition and hydrogen sulfide-resistant technology, which is applied in the field of rubber products, can solve problems such as the huge impact of hydrogen sulfide resistance, achieve excellent hydrogen sulfide corrosion resistance, excellent comprehensive performance, and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

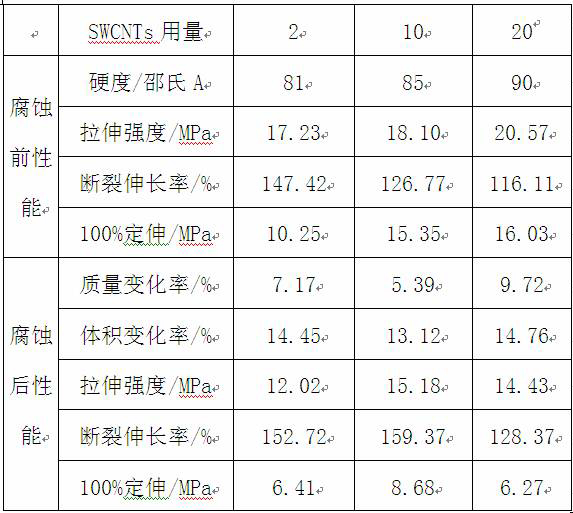

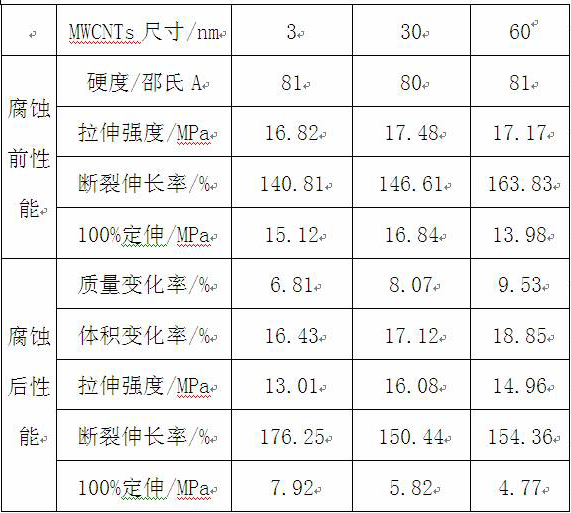

[0030] This example describes the comparative experimental situation of the hydrogen sulfide resistance performance of rubber compositions with different types of carbon nanotubes. The rubber composition is composed of the following components and parts by mass: 100 parts of tetrapropylene fluororubber, 1 part of sodium stearate, 2 parts of dicumyl peroxide, 2,2,4-trimethyl 1,2-dihydrogenated 1.5 parts of quinoline polymer, 35 parts of N550 carbon black, 10 parts of carbon nanotubes, 8 parts of triallyl cyanurate, and 2 parts of coumarone. The carbon nanotubes are single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs), both of which are 3nm in size, and armchair-shaped nanotubes are used. At a temperature of 100°C, the gas phase composition of 15MPa is 20%H 2 S, 5% CO 2 and 75%CH 4 , the results after 4 days of corrosion are shown in Table 1. It can be seen from Table 1 that the change rate of tensile strength and elongation at break of the rubb...

Embodiment 2

[0034] This example describes the comparative experimental situation of the hydrogen sulfide resistance performance of rubber compositions made of different types of single-walled carbon nanotubes. The rubber composition is composed of the following components and parts by mass: 100 parts of tetrapropylene fluororubber, 1.5 parts of sodium stearate, 4 parts of dicumyl peroxide, 2,2,4-trimethyl 1,2-dihydrogenated 2 parts of quinoline polymer, 35 parts of N550 carbon black, 10 parts of single-walled carbon nanotubes, 2 parts of triallyl cyanurate, 3.5 parts of coumarone. The single-walled carbon nanotubes are respectively armchair nanotubes, zigzag nanotubes and chiral nanotubes. At a temperature of 100°C, the gas phase composition of 15MPa is 20%H 2 S, 5% CO 2 and 75%CH 4 , the results after 4 days of corrosion are shown in Table 2. It can be seen from Table 2 that the tensile strength, elongation at break, and 100% modulus of the rubber composition added with armchair nano...

Embodiment 3

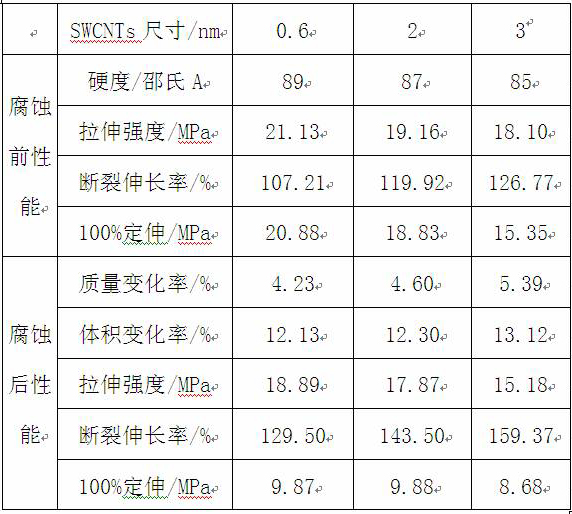

[0038] This example describes the comparative experimental situation of the hydrogen sulfide resistance performance of the rubber composition of armchair-shaped single-walled carbon nanotubes with different sizes. The rubber composition is composed of the following components and parts by mass: 100 parts of tetrapropylene fluororubber, 1.5 parts of sodium stearate, 6 parts of dicumyl peroxide, 2,2,4-trimethyl 1,2-dihydrogenated 3 parts of quinoline polymer, 35 parts of N550 carbon black, 10 parts of single-walled carbon nanotubes, 5 parts of triallyl cyanurate, and 5 parts of coumarone. Single-walled carbon nanotubes (SWCNTs) are all armchair-shaped carbon nanotubes with diameters of 0.6nm, 2nm, and 3nm. At a temperature of 100°C, the gas phase composition of 15MPa is 20%H 2 S, 5% CO 2 and 75%CH 4 , the results after 4 days of corrosion are shown in Table 3. It can be seen from Table 3 that the rubber composition with smaller armchair nanotubes has a better reinforcing eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com