Shutdown purging method for fuel cell system

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, electrolyte treatment of solid electrolyte batteries, etc., can solve the problem of affecting the purging effect, increasing the energy consumption of air compressors, increasing the use and maintenance costs, etc. problems, to achieve the effect of shortening the purging time, reducing the water production volume, and avoiding additional water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

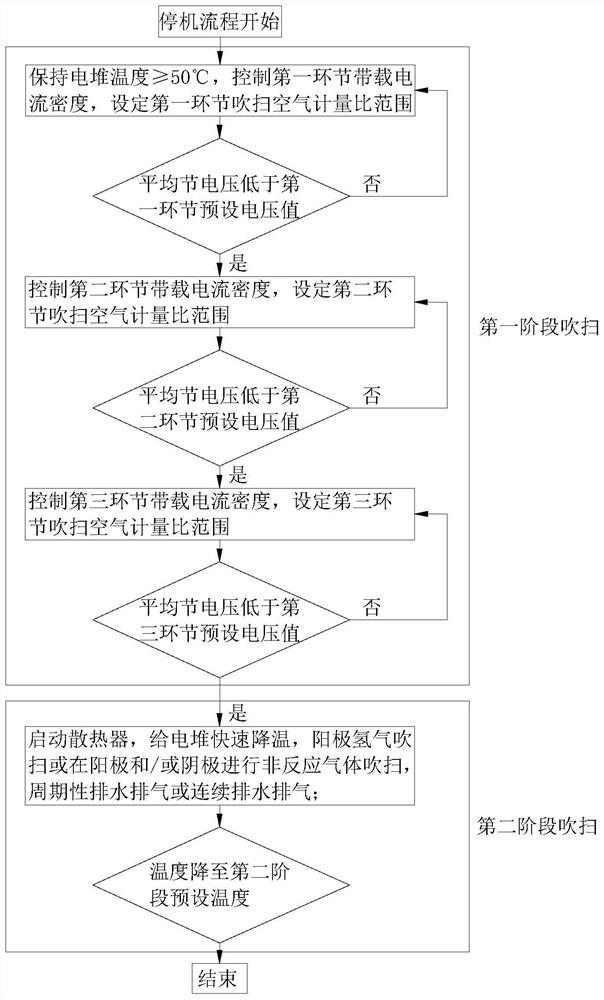

[0035] Such as figure 1 As shown, the fuel cell system shutdown purging method in this embodiment includes the following steps:

[0036] The first stage of purging: set the preset temperature of the first stage to 50°C, control the thermostat to maintain the temperature of the cooling medium at the inlet or outlet of the fuel cell at ≥ 50°C, and classify the loading current in descending order, at least A link:

[0037] For example, in the first link, the loading current density is 0.4A / cm 2 current, carry out on-load purge. When the average junction voltage drops to 0.8V, enter the second stage, and the loading current density is 0.3A / cm 2 At this time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com