Electroplating wastewater reclaimed water recycling process and system

A technology for electroplating wastewater and reclaimed water, applied in water/sewage treatment, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc. Achieve the effect of reducing conductivity, strong precipitation ability and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

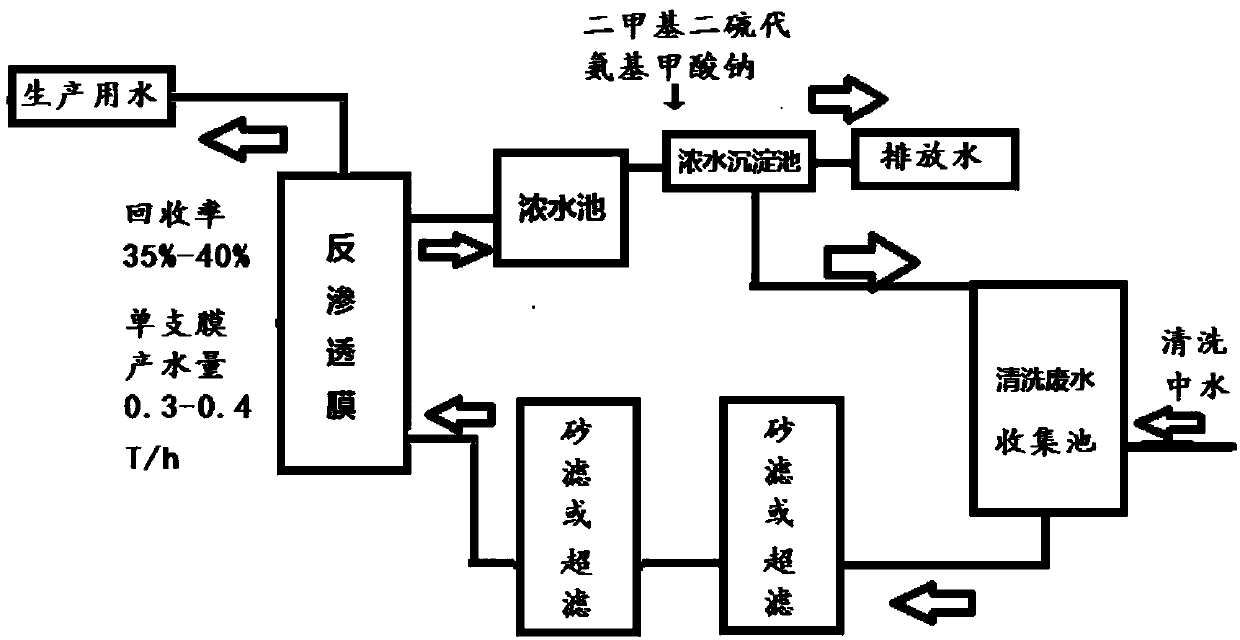

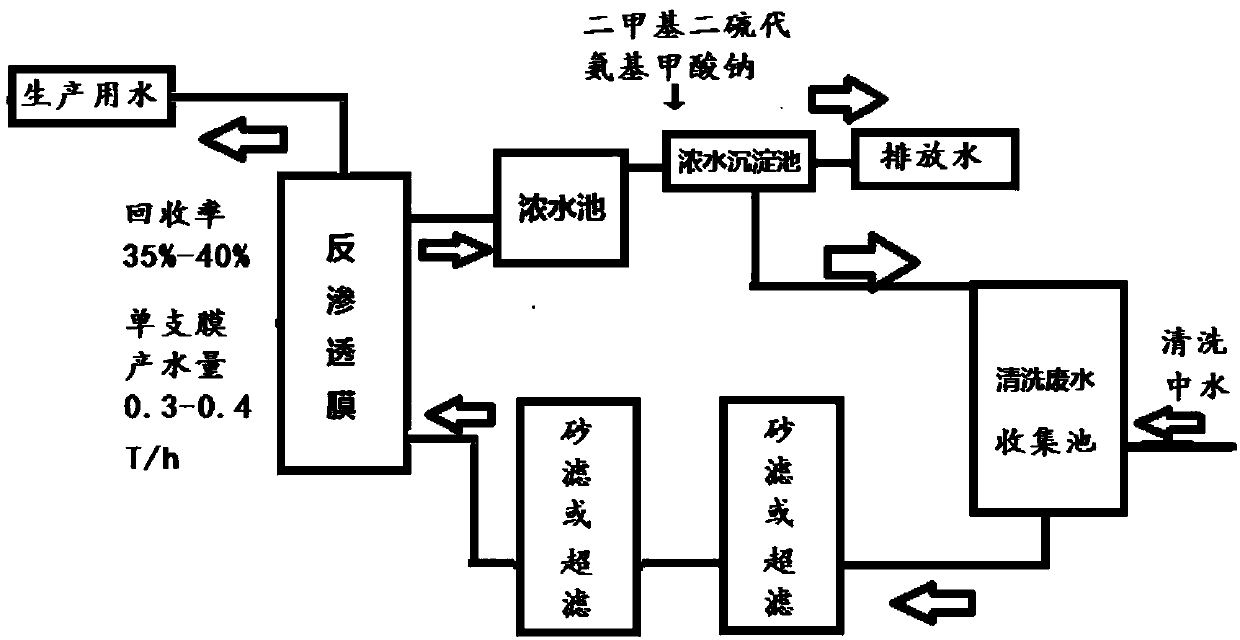

[0039] like figure 1 As shown, a water reuse system for electroplating wastewater provided in this embodiment includes a cleaning wastewater collection tank, a filtration system one, a filtration system two, a reverse osmosis system, a concentrated water collection tank, and a concentrated water collection tank arranged in sequence along the direction of water flow. water sedimentation tank;

[0040] The cleaning wastewater collection pool is used to collect the reclaimed water to be treated; the first filter system is a sand filter or ultrafiltration system, which is used to filter the reclaimed water to be treated for the first time;

[0041] The second filtration system is a sand filtration or ultrafiltration system, which is used for the second filtration of the reclaimed water to be treated;

[0042] The reverse osmosis system treats the wastewater after the second filtration; the standardized water production of a single membrane is designed according to 0.3-0.4T / h, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com