Device and method for testing high-temperature erosion resistance, corrosion resistance and adhesion characteristics of coating material

A coating material, high temperature resistant technology, applied in the field of material performance testing devices, to achieve the effects of simple assembly, uniform temperature distribution and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

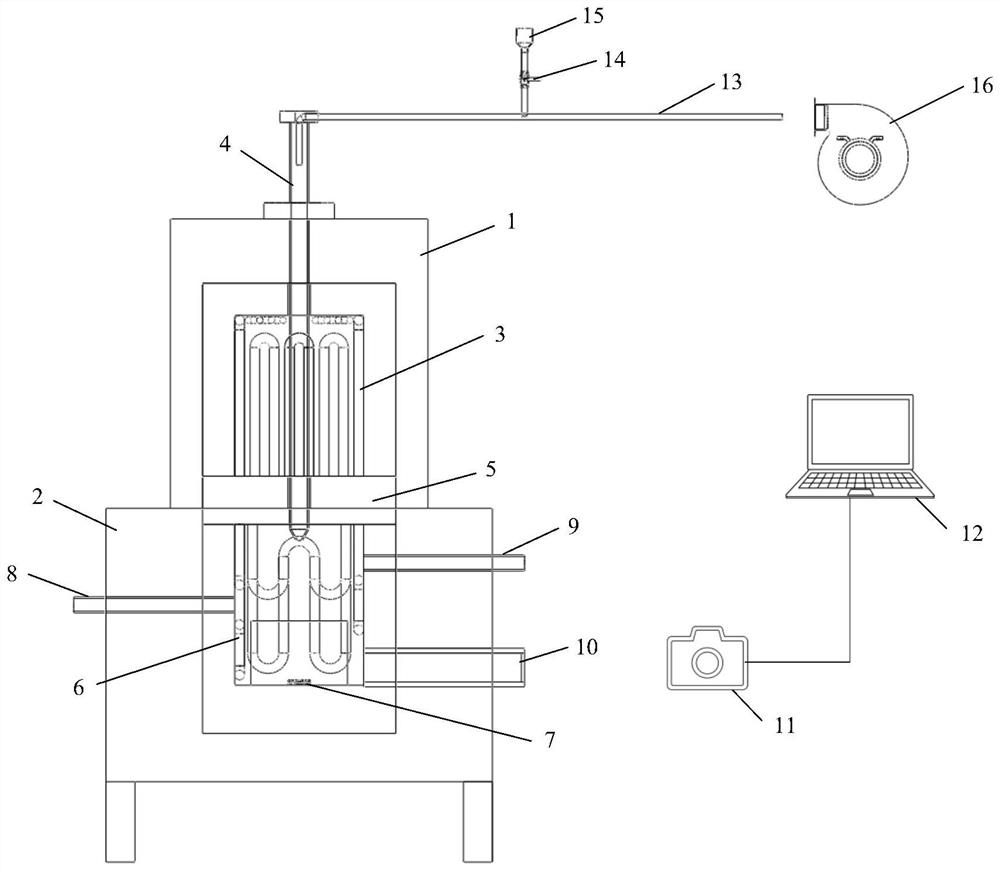

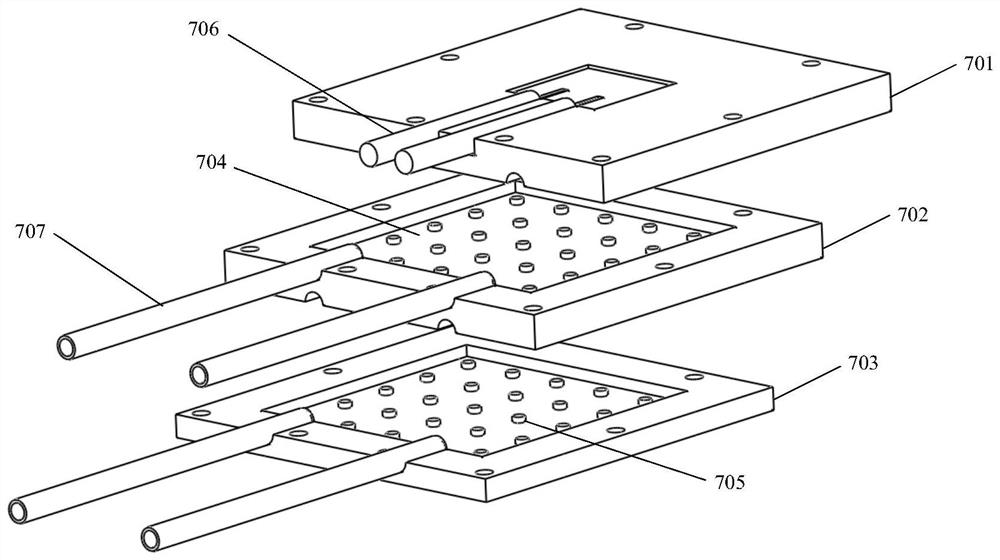

[0025] Example: refer to figure 1, a multifunctional device for testing the high-temperature erosion, corrosion and adhesion properties of coating materials, including a high-temperature frit furnace 1, a high-temperature electric furnace 2, a temperature-controllable sample holder 7, a pipeline 13, a centrifugal blower 16, and a storage tank 15 , feed valve 14, CCD camera 11 and computer 12. The high-temperature frit furnace 1 is placed on the upper part of the high-temperature electric furnace 2 , and the two are connected through a heat insulating layer 5 . The high-temperature frit furnace 1 is provided with a silicon carbide rod 3 as the first heating element, and the high-temperature frit furnace 1 is provided with a corundum tube 4 inside, and the bottom of the corundum tube 4 is provided with an outlet, and the corundum tube 4 is filled with molten material. The heat-insulating interlayer 5 is provided with an opening, and the high-temperature electric furnace 2 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com