High-temperature water vapor corrosion resistant coating for surface of zirconium alloy cladding tube of nuclear power plant and preparation method of high-temperature water vapor corrosion resistant coating

A technology for corrosion coating and cladding tube, which is applied in the field of high temperature water vapor corrosion resistant coating for the surface of zirconium alloy cladding tube in nuclear power plants and its preparation, which can solve the problems of inability to achieve and achieve the effect of good protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

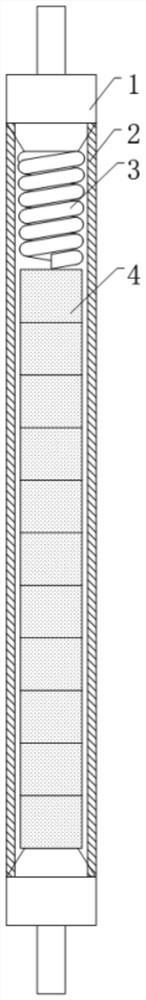

[0031] The present invention also provides a method for preparing a high-temperature water vapor corrosion-resistant coating on the surface of a zirconium alloy cladding tube of a nuclear power plant, comprising the following steps:

[0032] S1. Pretreatment: Use alcohol, acetone and other cleaning agents to clean the zirconium alloy cladding tube to remove surface dirt, perform sandblasting treatment, and seal the cladding tube after drying;

[0033] S2. Coating the bonding layer 2: setting the bonding layer 2 on the surface of the zirconium alloy cladding tube substrate 1 by magnetron sputtering, multi-arc ion plating, thermal spraying, cold spraying, and 3D laser coating;

[0034] S3. Coating the overlapping composite film layer 3: coating the overlapping composite film layer 3 on the surface of the zirconium alloy cladding tube substrate 1 located on the bonding layer 2 by using magnetron sputtering, multi-arc ion plating, and atomic layer deposition.

[0035] Through the ...

Embodiment 1

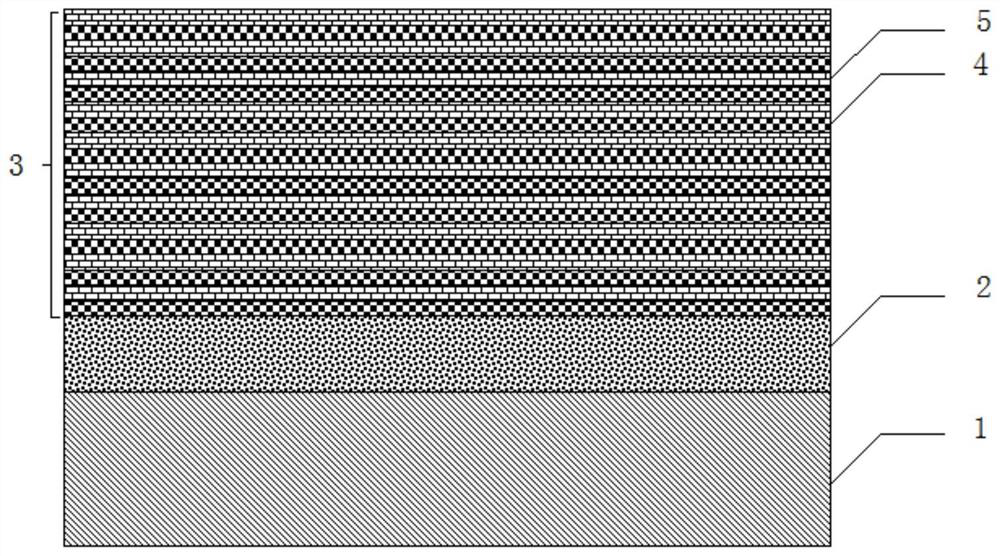

[0037] Prepare metal Cr on the surface of the zirconium alloy cladding tube as the bonding layer 2, and the thickness of this layer is 2 μm; prepare Cr / Cr 3 C 2 Overlapping layers, the layer thickness is 20μm, in which the Cr phase layer is equiaxed crystal morphology, each layer thickness is 60nm, Cr 3 C 2 The thickness of each phase layer is 40nm.

[0038] The characteristics in the embodiment of the present invention are: 1, adopt Cr as bonding layer 2, this layer can buffer zirconium alloy and Cr 3 C 2 The difference in thermal expansion coefficient between them can enhance the bonding performance of the coating and reduce the risk of coating cracking and peeling; 2. Cr / Cr 3 C 2 The overlapping layer is 20μm, in which the Cr phase is 60nm per layer, and the Cr phase 3 C 2 Each layer is 40nm, and this embodiment can form 200 layers of dense Cr equiaxed crystal film layers. This structure can greatly reduce the formation of oxygen channels and enhance the ability to r...

Embodiment 2

[0041] Metal Nb is prepared on the surface of the zirconium alloy cladding tube as the bonding layer 2, and the thickness of the layer is 1 μm; the Cr / Si overlapping composite film layer 3 is prepared, and the thickness of the layer is 20 μm, wherein each layer of the Cr phase layer is 60 nm, and the Si phase layer 40nm per layer.

[0042] The characteristics in the embodiment of the present invention are: 1. Utilize the similar thermal expansion coefficients of Cr, Zr, and Nb, and adopt Nb as the bonding layer 2 to slow down the difference in thermal expansion coefficient between the zirconium alloy and the metal Cr, and enhance the coating bonding performance. Reduce the risk of coating cracking and peeling; 2. In the Cr / Si overlapping layer, Cr maintains equiaxed crystal morphology, which hinders the formation of oxygen channels. In this embodiment, the thickness of a group of Cr phase layer and Si phase layer is 100nm. Therefore, 200 layers of high-density Cr films can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com