High-temperature antioxidant multi-layer composite coating on surface of carbon-based material and preparation method of coating

A high-temperature anti-oxidation, carbon-based material technology, applied in the field of surface coatings, can solve the problems of complex coating preparation methods, inconvenient preparation of uniform coatings, overheating of Ir coatings, etc., and achieve excellent oxygen diffusion resistance, good physical and chemical properties Chemical Compatibility, Fast Deposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

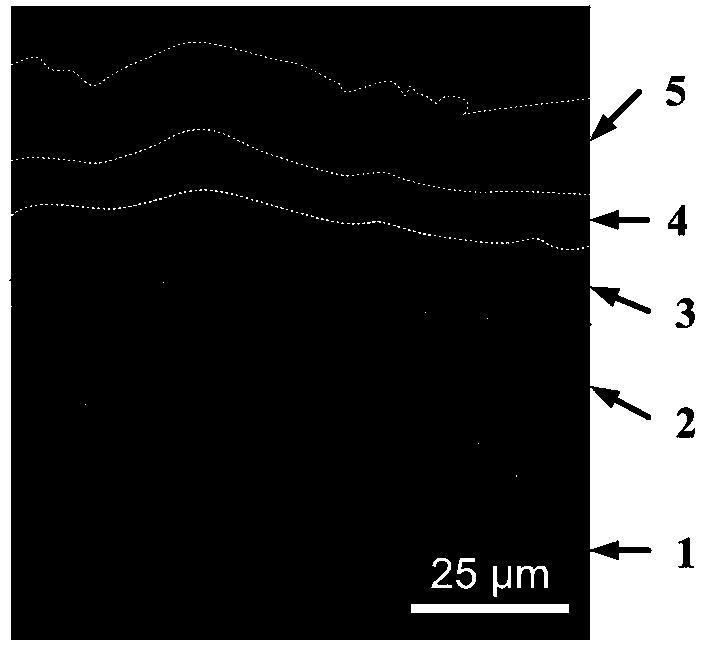

[0032] A kind of carbon base material surface high temperature anti-oxidation multi-layer composite coating of the present invention, such as figure 1 As shown, the multilayer composite coating is arranged on the surface of a carbon-based material substrate 1, and the carbon-based material substrate 1 is specifically a graphite substrate. The multilayer composite coating includes a Re transition layer 2 and an Ir coating layer 3 arranged in sequence from bottom to top. and Ir-Al coating, where the Ir-Al coating is IrAl coating 4 (bottom) and IrAl 2.7 -IrAl 3 Mixed coating 5 (top) constitutes a double-layer coating; the Re transition layer 2 has a thickness of 20 μm, the Ir coating 3 has a thickness of 13 μm, and the Ir-Al coating has a thickness of 22 μm.

[0033] A method for preparing a high-temperature oxidation-resistant multilayer composite coating on the surface of a carbon-based material according to the present embodiment, comprising the following steps:

[0034] (1)...

Embodiment 2

[0046] A high-temperature oxidation-resistant multilayer composite coating on the surface of a carbon-based material according to the present invention, the multilayer composite coating is arranged on the surface of a carbon-based material substrate 1, the carbon-based material substrate 1 is specifically a graphite substrate, and the multilayer composite coating includes The Re transition layer 2, the Ir coating 3 and the Ir-Al coating are sequentially arranged from bottom to top, wherein the Ir-Al coating is a single-layer IrAl coating 4; the thickness of the Re transition layer 2 is 200 μm, and the thickness of the Ir coating 3 The thickness is 6 μm, and the thickness of the Ir-Al coating is 5 μm.

[0047] A method for preparing a high-temperature oxidation-resistant multilayer composite coating on the surface of the above-mentioned carbon-based material, comprising the following steps:

[0048] (1) The carbon-based material is graphite. First, the graphite is polished with...

Embodiment 3

[0054] A high-temperature oxidation-resistant multilayer composite coating on the surface of a carbon-based material according to the present invention, the multilayer composite coating is arranged on the surface of a carbon-based material substrate 1, and the carbon-based material substrate 1 is specifically a carbon / carbon composite material substrate. The composite coating includes Re transition layer 2, Ir coating 3, and Ir-Al coating arranged sequentially from bottom to top, where the Ir-Al coating is IrAl coating 4 and IrAl coating 2.7 -IrAl 3 A double-layer coating composed of mixed coating 5; the thickness of the Re transition layer 2 is 60 μm, the thickness of the Ir coating 3 is 92 μm, and the thickness of the Ir-Al coating is 10 μm.

[0055] A method for preparing a high-temperature oxidation-resistant multilayer composite coating on the surface of the above-mentioned carbon-based material, comprising the following steps:

[0056] (1) The carbon-based material is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com