End point judgment device and method for distillation process for preparing sponge titanium by magnesiothermy

A technology of end point judgment and titanium sponge, which is applied in measuring devices, furnace monitoring devices, lighting and heating equipment, etc., can solve problems such as abnormal pressure changes, waste of resources, theoretical inaccuracy, etc., and achieve reliable values and accurate end point judgments , the effect of clear principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

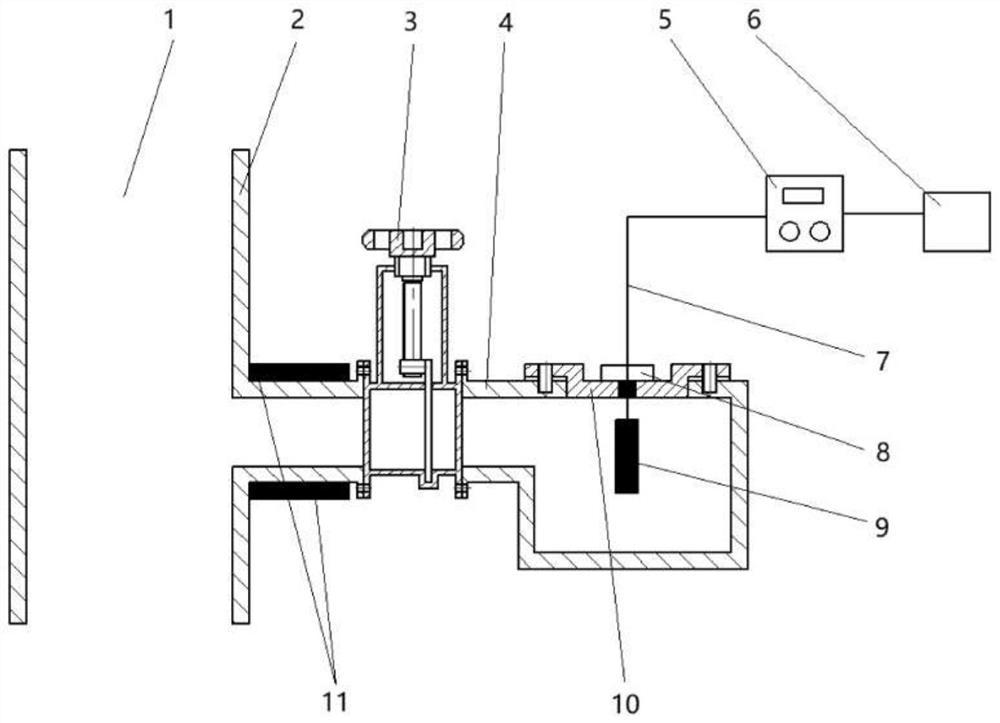

[0045] Such as figure 1 As shown, a terminal judging device for the distillation process of sponge titanium by magnesia method: it includes a casing 4, and the casing is installed on the steam pipe between the distillation furnace and the condensation furnace of the sponge titanium equipment by magnesia method through the connecting flange 2 On the pipe wall of road 1, a valve 3 is provided between the connecting flange and the casing, and the valve is used to control the connection or isolation between the inner cavity of the casing and the steam pipeline, and a measuring probe 9 is arranged in the inner cavity of the casing. The measuring probe is equipped with a quartz crystal oscillator, and the casing is provided with a loam cake 10, the measuring probe is fixed on the loam cake, and the measuring probe is connected to the measuring instrument 5 through the connecting wire 7 passing through the loam cake, The contact between the upper cover and the connection line is also...

Embodiment 2

[0062] This embodiment adopts the device described in Embodiment 1. The difference from Embodiment 1 is that the measuring instrument used in this embodiment is a resonance frequency measuring instrument / resonance frequency time change rate measuring instrument. After step S1 and before S2, it needs to be turned on Measuring instrument, measure the resonant frequency of the quartz crystal oscillator in the probe, record it as the initial frequency f 0 ;

[0063] All the other steps are identical with embodiment 1;

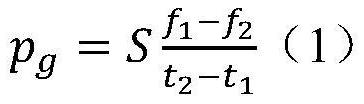

[0064] When the measuring instrument adopts a resonant frequency measuring instrument to measure the resonant frequency value f of the quartz crystal oscillator, record the time t respectively 1 The resonant frequency f at 1 and time t 2 The resonant frequency f at 2 , and use the following formula (1) to calculate the space partial pressure p of the impurity vapor g :

[0065]

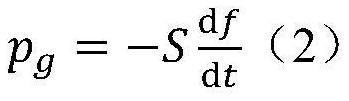

[0066] When the measuring instrument adopts the time rate of change of resona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com