Diamond composite material and valve made of diamond composite material

A composite material and diamond technology, which is applied in the field of diamond composite materials and valves made of diamond composite materials, can solve problems such as mis-opening of electric valves, corrosion of valve body and valve core, etc., and achieve good corrosion resistance and wear resistance, Effect of improving corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

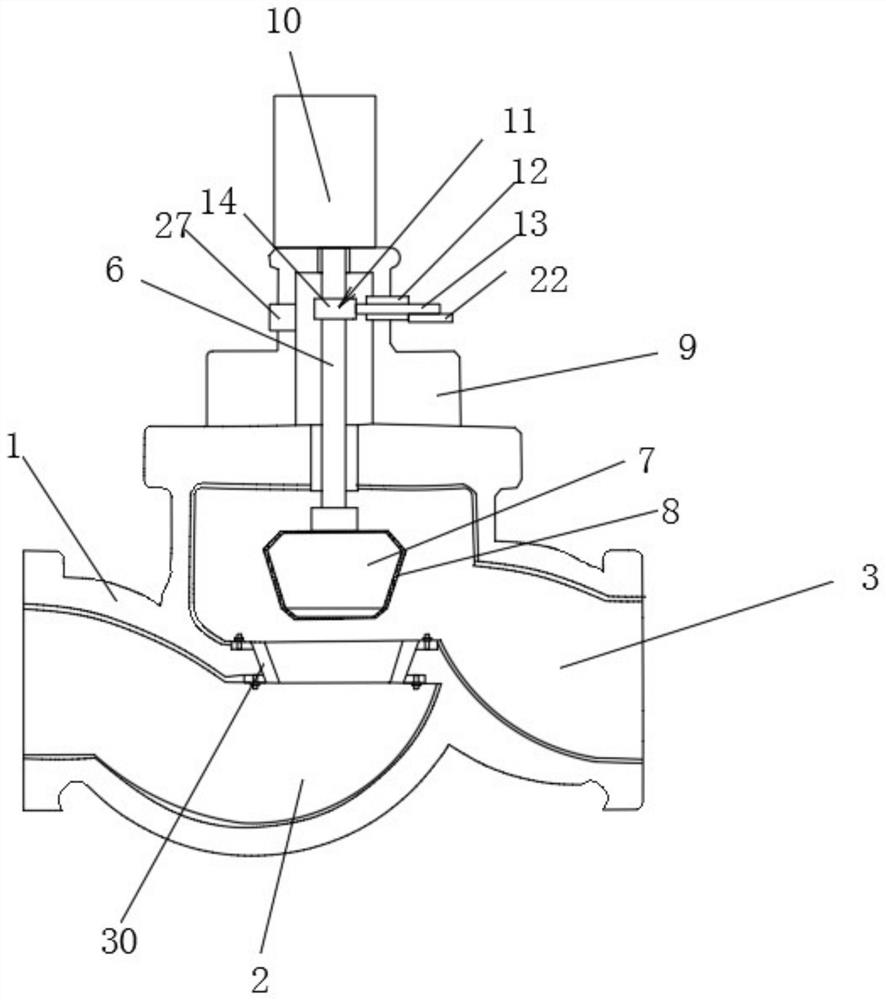

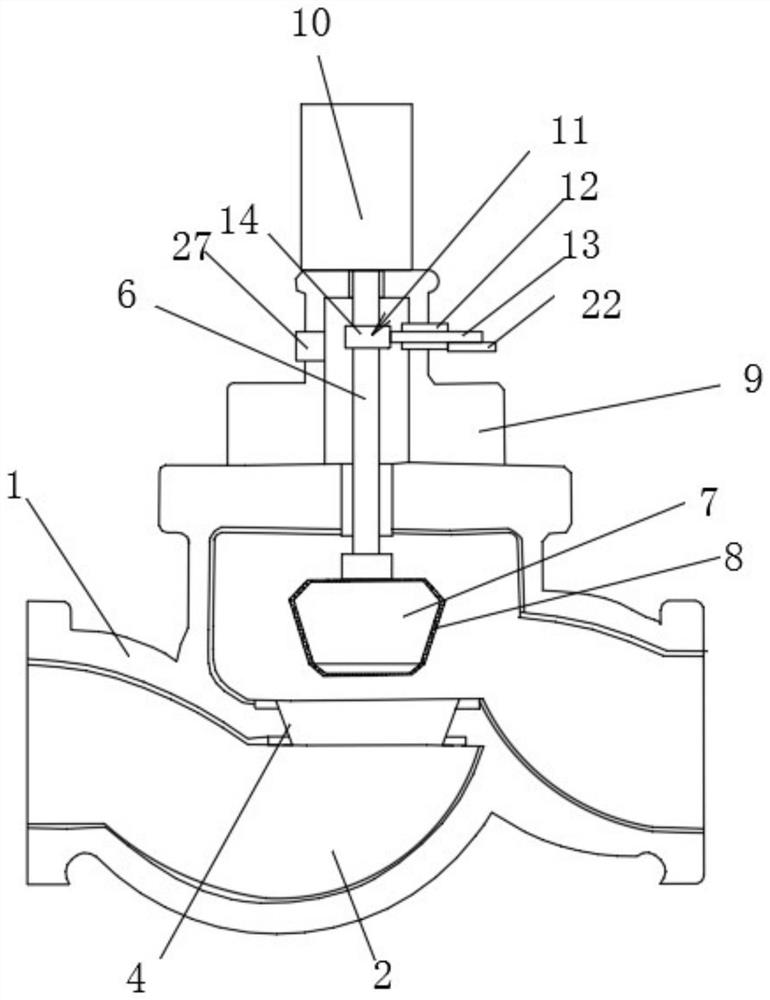

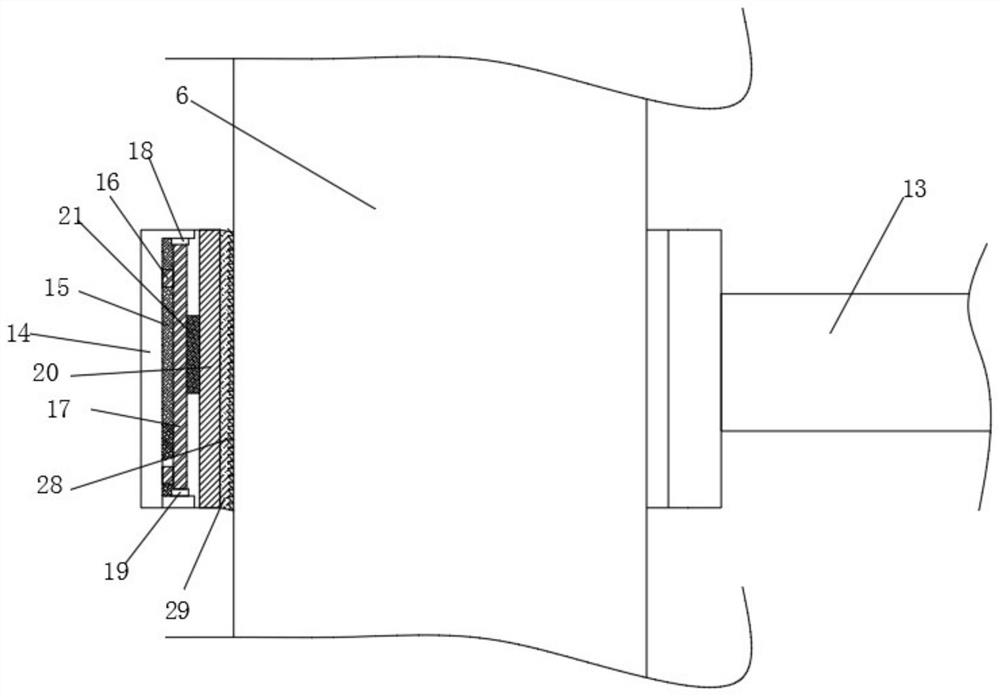

[0031] Embodiment: A kind of diamond composite material of the present invention, this diamond composite material comprises 30%~80% diamond powder, 10~40% graphite powder and 10~30% phenolic resin by weight;

[0032] The diamond composite material is prepared by the following steps:

[0033]Add diamond powder and graphite powder into liquid phenolic resin with a certain viscosity and mix uniformly to form a mixed slurry. After the mixed slurry is solidified, grind it to obtain a powdery diamond composite material. It is made by mixing 30% to 80% of diamond powder, 10 to 40% of graphite powder and 10 to 30% of phenolic resin. Add diamond powder and graphite powder to liquid phenolic resin with a certain viscosity and mix evenly to form a mixture. Slurry, after the mixed slurry is solidified, grind to obtain powdery diamond composite material, so that the powdery diamond composite material has better corrosion resistance and wear resistance; it is conducive to sintering on the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com