Thermocouple, temperature monitoring equipment and brazing flame temperature real-time monitoring method

A technology for thermocouples and monitoring equipment, which is applied in the field of thermocouples, temperature monitoring equipment and brazing flame temperature real-time monitoring, which can solve problems such as virtual welding, inability of operators to accurately control flame temperature, poor thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

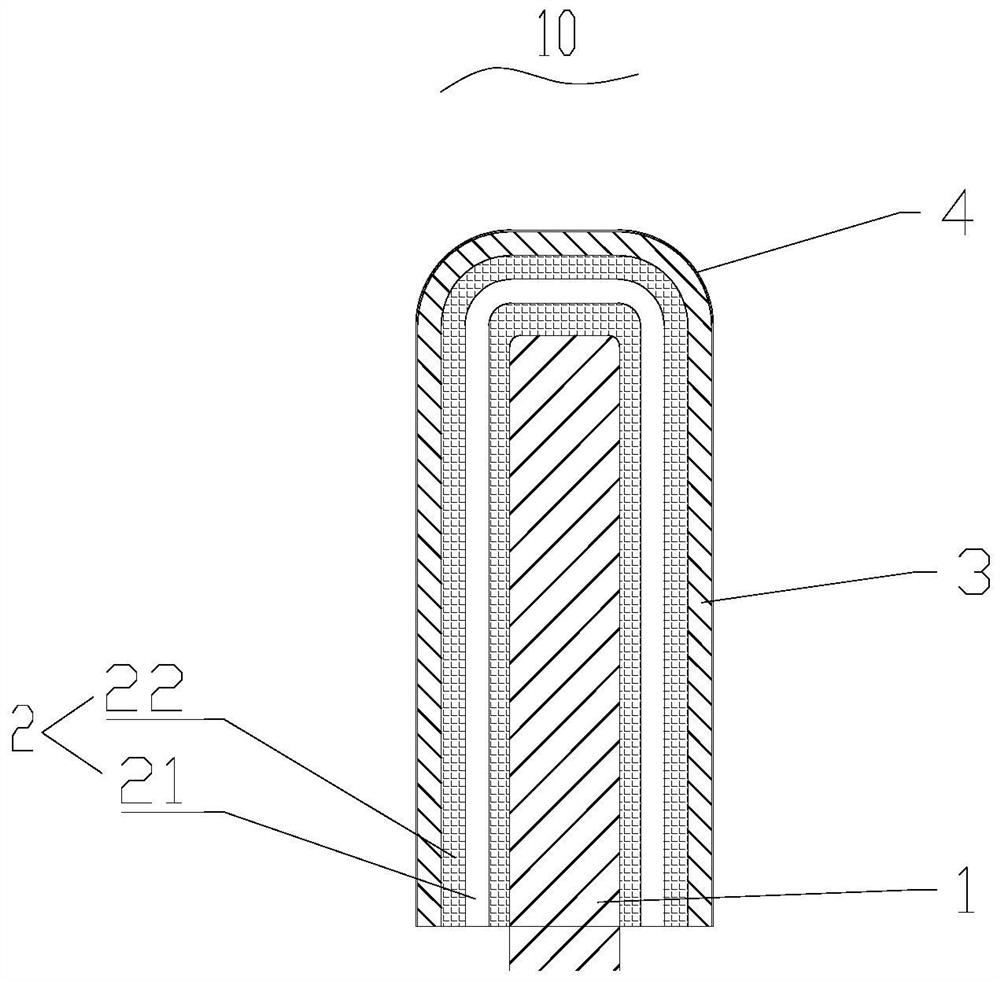

[0033] like figure 1 As shown, a thermocouple includes: a temperature sensing body 1 and a protective cover arranged outside the temperature sensing body 1, the protective cover includes a protective substrate 2, a high-aluminum protective sleeve 3 and a nickel-aluminum ion modification Layer 4, the protective substrate 2 is arranged on the outer wall of the temperature sensing body 1, the high-aluminum protective cover is arranged on the outer wall of the protective substrate 2, and the nickel-aluminum ion modified layer 4 is arranged on the high-alumina Protect the outer wall of the sleeve 3 .

[0034] The protective substrate 2 plays a main protective role, and the high-aluminum protective sleeve 3 plays an auxiliary protective role. In this embodiment, the protective substrate 2 includes a magnesium oxide filling layer 21, and a graphite protective sleeve 22 is arranged in the magnesium oxide filling layer 21. The structure of the protective substrate 2 from the inside to...

Embodiment 2

[0052] This embodiment only describes the difference from Embodiment 1, and other technical features are the same as the above-mentioned embodiment. In this embodiment, the temperature sensing body 1 includes a positive electrode and a negative electrode, and the weight percentage of the material of the positive electrode is: 94.84% tungsten, 5% rhenium, 0.04% Si, 0.04% Al, 0.08% Cobalt; the weight percentage of the negative electrode material is: 73.84% tungsten, 26% rhenium, 0.04% Si, 0.04% Al, 0.08% cobalt.

[0053] In this embodiment, the tungsten content of the tungsten-rhenium-cobalt temperature sensor is relatively high, the cobalt content is relatively low, and the temperature offset of the temperature sensor is relatively small.

Embodiment 3

[0055] This embodiment only describes the difference from Embodiment 1, and other technical features are the same as the above-mentioned embodiment. The temperature sensing body 1 includes a positive electrode and a negative electrode, and the weight percentage of the material of the positive electrode is: 94.97% tungsten, 5% rhenium, 0.01% Si, 0.01% Al, 0.01% cobalt; the material of the negative electrode The weight percentages are: 73.97% tungsten, 26% rhenium, 0.01% Si, 0.01% Al, 0.01% cobalt.

[0056] In this embodiment, the tungsten-rhenium-cobalt temperature sensor has high tungsten content and low cobalt content, and the mechanical properties of the temperature sensor are poorer than those of Example 1-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com