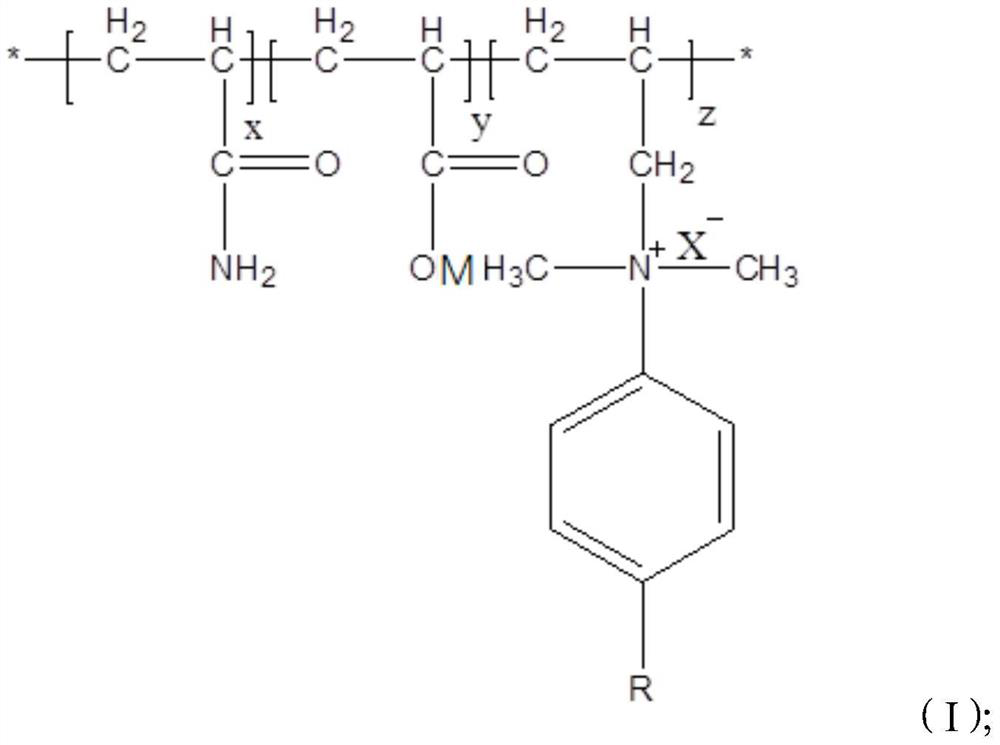

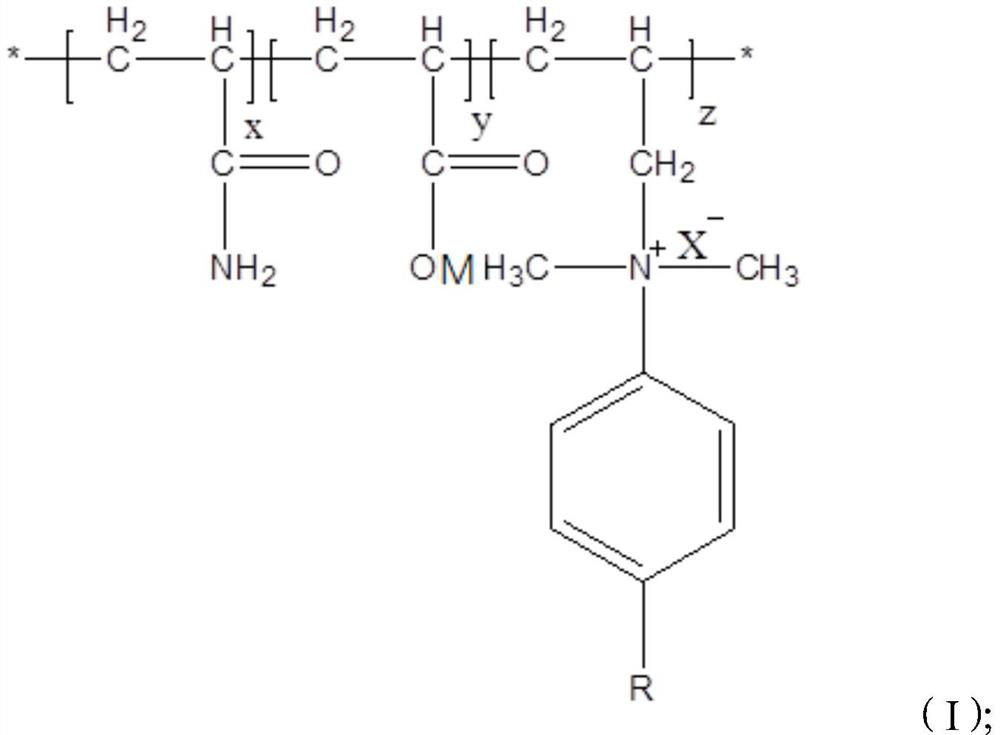

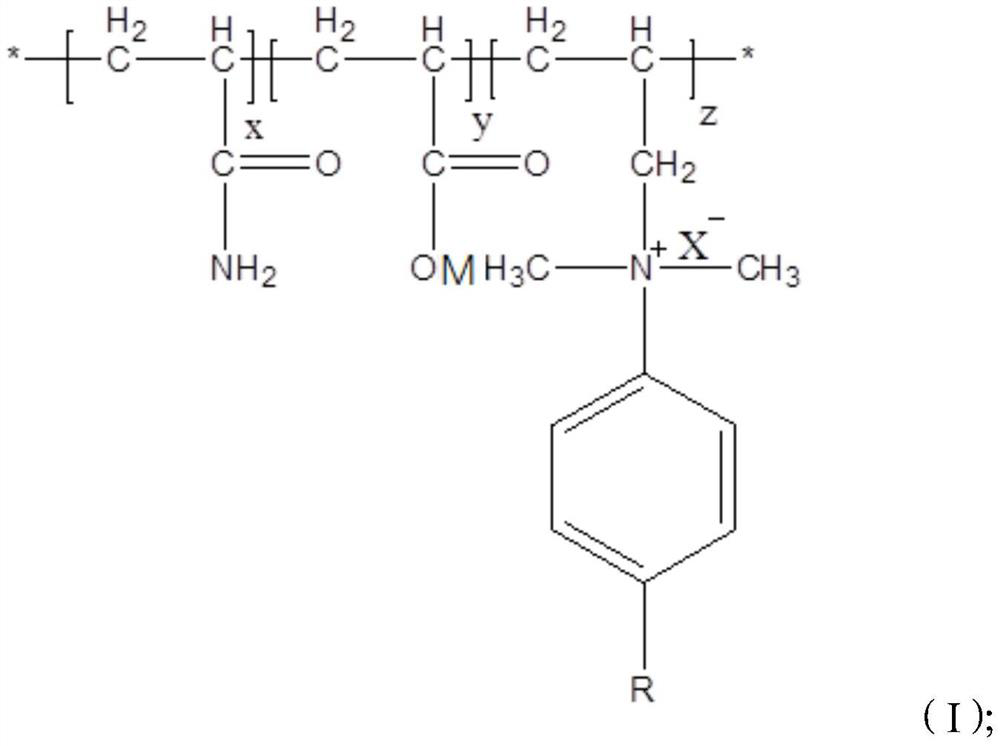

Self-crosslinking polymer, oil field profile control and flooding agent and preparation method

A polymer and self-crosslinking technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of irreversible gelation, the strength of the gel system of coagulation and polymerization reactants, and the long-term stability of plugging integrity. , achieve excellent temperature and salt resistance, improve temperature and salt resistance and aging stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] On the other hand, the embodiment of the present invention also provides a preparation method of the above self-crosslinking polymer, wherein the preparation method includes:

[0042] The acrylamide monomer and the allyl quaternary ammonium salt are polymerized under the action of an initiator to obtain a polymerized reactant.

[0043] Among them, the acrylamide monomer and the allyl quaternary ammonium salt monomer open the double bond under the condition of the initiator to form a polymer, which is the process of forming a macromolecule from a small molecule.

[0044] Under the action of the alkali metal salt of the hydrolyzing agent, the polymerized reactants are hydrolyzed at high temperature to obtain the self-crosslinked polymer.

[0045] Wherein, hydrolysis is a process in which acrylamide monomer units are hydrolyzed to form acrylate units. For example, the acrylate units can be sodium acrylate units, which can increase the electrostatic repulsion between macrom...

Embodiment 1

[0062] This embodiment provides a kind of self-crosslinking polymer, and its preparation method is as follows:

[0063] Water, acrylamide, and N,N-dimethyl-(p-octadecylbenzene)-allyl ammonium chloride (that is to say, the R group is octadecyl) are sequentially added to the reaction vessel, wherein, The molar ratio of acrylamide:N,N-dimethyl-(p-octadecylbenzene)-allyl ammonium chloride is 99.0:1.0, and the total monomer concentration in the polymerization system is controlled to be 25%. At 5°C, Add a composite initiator composed of potassium persulfate and sodium bisulfite to the polymerization system to initiate polymerization, wherein the mass ratio of potassium persulfate to sodium bisulfite is 1:1, and the mass of potassium persulfate is 0.015% of the total mass of monomers. %. Place the polymerization system in an adiabatic environment, and stop the reaction when the central temperature of the polymerization system rises to the highest and remains unchanged. After the co...

Embodiment 2

[0067] This embodiment 2 provides a self-crosslinking polymer, the preparation method of the self-crosslinking polymer is the same as the polymerization method involved in embodiment 1, the difference is: acrylamide: N,N-dimethyl-( Octadecylbenzene)-allyl ammonium chloride molar ratio is 99.9:0.1.

[0068] Ubbelohde viscometer (0.55 mm diameter) was used to test the polymer molecular weight of the self-crosslinking polymer obtained in Example 2 according to GB / T 12005.10-92, and the viscosity-average molecular weight was 18.15 million.

[0069] The dry powder of the self-crosslinking polymer obtained in Example 2 was dissolved at 45°C in a solution with a total salinity of 4.0×10 4 mg / L, the total concentration of calcium and magnesium ions is 1500mg / L, and the polymer solution with a concentration of 10000mg / L is prepared, and the polymer dissolution time is 1.5h, 90°C, 7.34s -1 The viscosity test under the DV-II viscometer is 340.5mPa·s, and the viscosity retention rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com