Processing technology of glass panel

A processing technology, glass panel technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., to achieve the effect of clean surface, increased compressive stress and tensile stress, and reduced adhesion of dust and fingerprints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

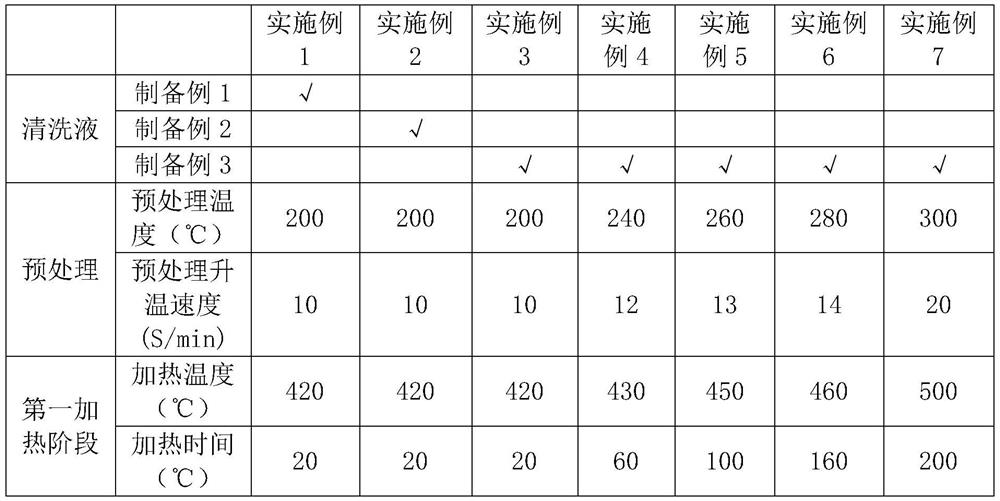

Examples

preparation example 1

[0041] A kind of cleaning fluid, is made by following steps:

[0042] Weigh 0.1 kg of hydrogen peroxide, 0.4 kg of concentrated sulfuric acid and 0.5 kg of organosilane and mix them uniformly to prepare a cleaning solution. The organosilane used in this implementation is phenyltrimethoxysilane in the alkoxysilane, and the mass fraction of concentrated sulfuric acid is 70%.

preparation example 2

[0044] A kind of cleaning fluid, is made by following steps:

[0045] Weigh 0.2 kg of hydrogen peroxide, 0.5 kg of concentrated sulfuric acid and 0.3 kg of organosilane and mix them uniformly to prepare a cleaning solution. The organosilane used in this implementation is di-tert-butoxydiacetoxysilane in acetoxysilane, and the mass fraction of concentrated sulfuric acid is 80%.

preparation example 3

[0047] A kind of cleaning fluid, is made by following steps:

[0048] Weigh 0.3 kg of hydrogen peroxide, 0.4 kg of concentrated sulfuric acid and 0.3 kg of organosilane and mix them uniformly to prepare a cleaning solution. The organosilane used in this implementation is aminosilane which is 3-aminopropyltriethoxysilane, and the mass fraction of concentrated sulfuric acid is 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com