Raw blank forming equipment for forming powder metallurgy nut

A technology of powder metallurgy and forming equipment, applied in the field of original blank forming equipment for powder metallurgy nut forming, can solve the problems of low work efficiency, time-consuming operation, high labor cost, and achieve the effect of saving labor and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

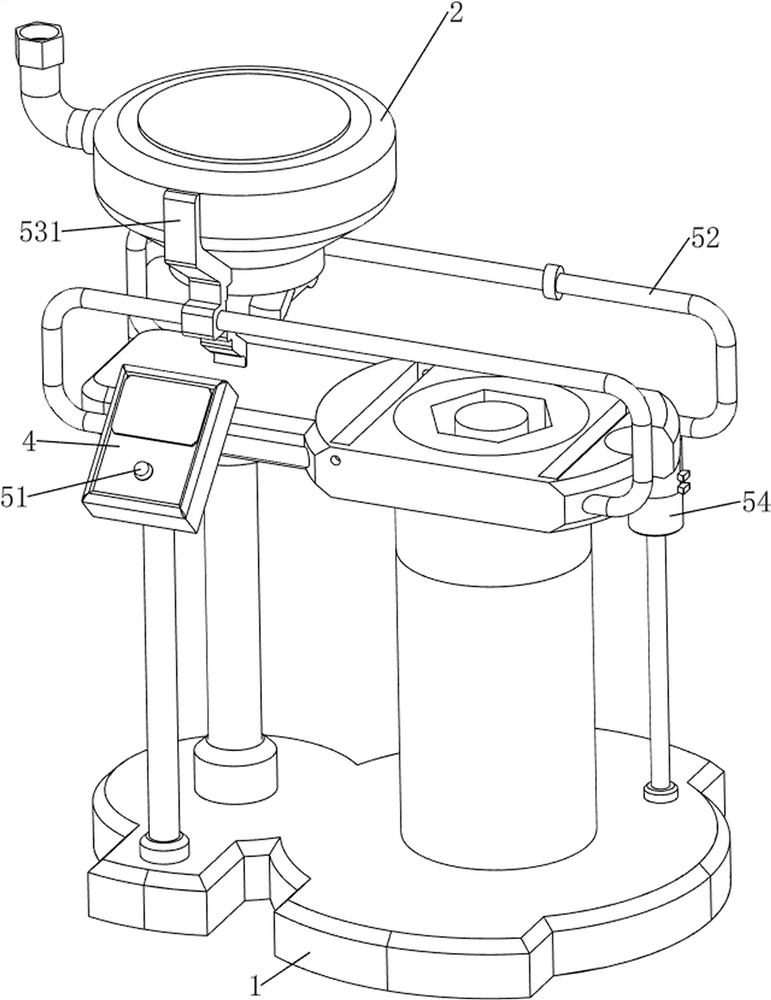

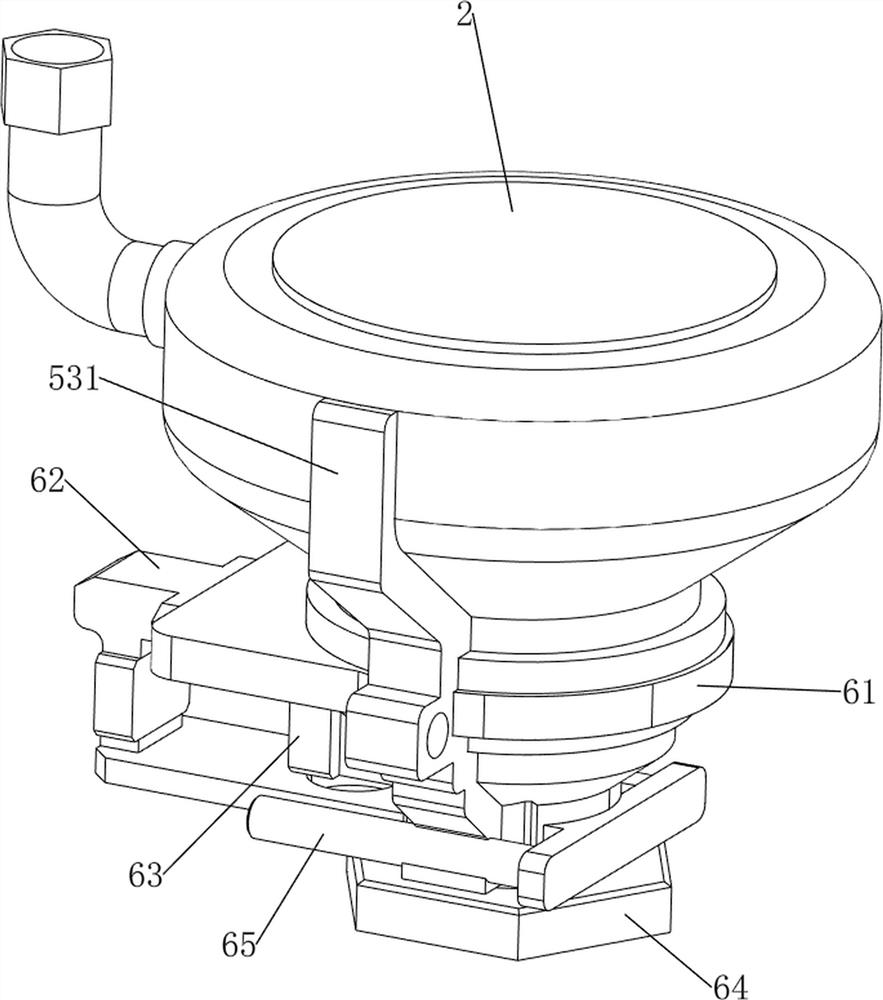

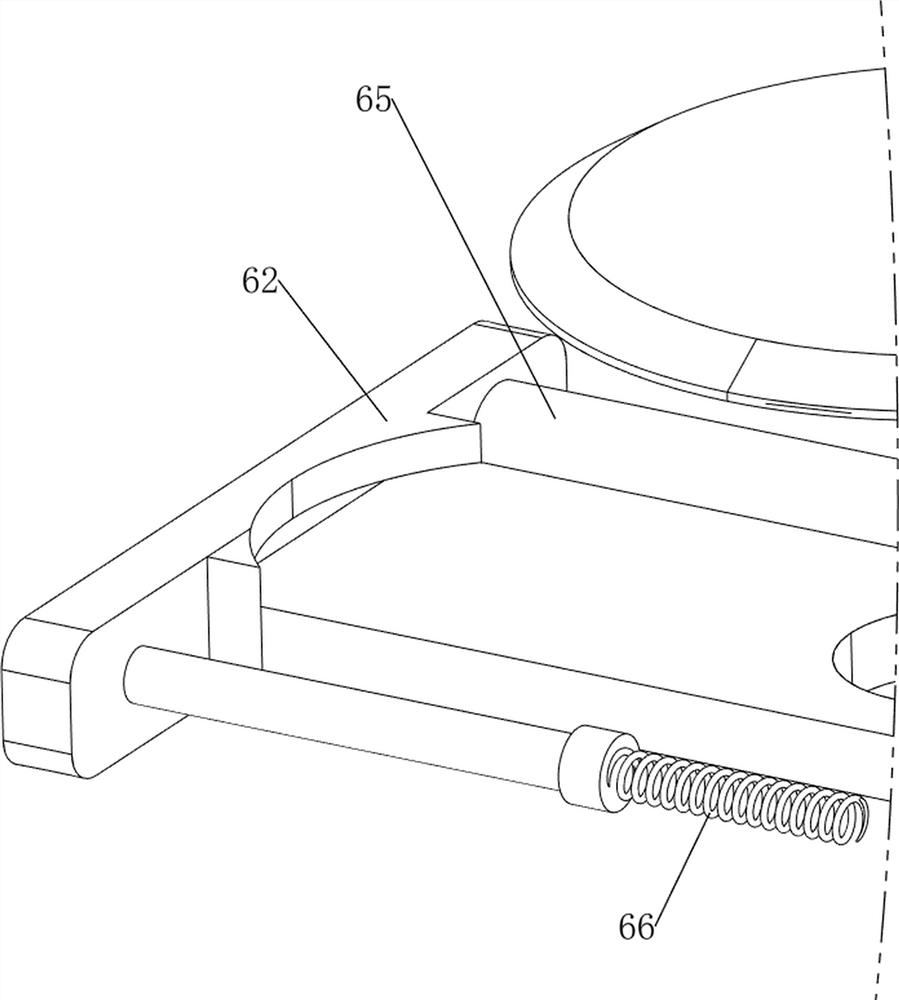

[0037] A kind of blank forming equipment for powder metallurgy nut forming, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 14 and Figure 15As shown, it includes a main frame 1, a material box 2, a briquetting block 3, a control box 4, a feeding mechanism 5, a quantitative mechanism 6, a compression mechanism 7 and an extrusion mechanism 8. The main frame 1 is provided with a feeding mechanism 5, and the feeding mechanism 5 is provided with a material box 2, and a control box 4 is provided on the left front side of the top side of the main frame 1. The control box 4 is connected with the feeding mechanism 5. A switching power supply, a control module and a power supply module are installed in the control box 4. The switching power supply is a powder Metallurgical nut forming is powered by the original blank forming equipment. The output end of the switching power sup...

Embodiment 2

[0048] On the basis of Example 1, such as figure 1 , figure 2 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, a blanking mechanism 9 is also included, and the blanking mechanism 9 includes a geared motor 91, a screw 92, a movable block 93, a first slideway 94 and a second slideway 95, and a geared motor is installed on the upper part of the front side of the main body frame 1. 91, the geared motor 91 is connected to the control module through the forward and reverse module of the DC motor, and the inner side of the upper part of the main frame 1 is rotated with a screw 92, which is connected to the output shaft of the geared motor 91, and the screw 92 is screwed with a movable block 93 , the movable block 93 is slidably connected with the main frame 1, the upper right part of the front part of the main frame 1 is provided with a first slideway 94, the upper side of the main frame 1 is provided with a second slideway 95, and the second slideway 95 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com