Preparation method of carbon cloth loaded zinc oxide/silver phosphate composite photocatalytic material

A technology of composite photocatalysis and zinc oxide, applied in the field of photocatalytic materials, can solve the problems that hinder large-scale application in the field of photocatalysis, lack of novelty in composite ideas, poor cycle performance and stability, etc., to promote the separation of photogenerated electrons and holes, Good prospects for industrial application and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

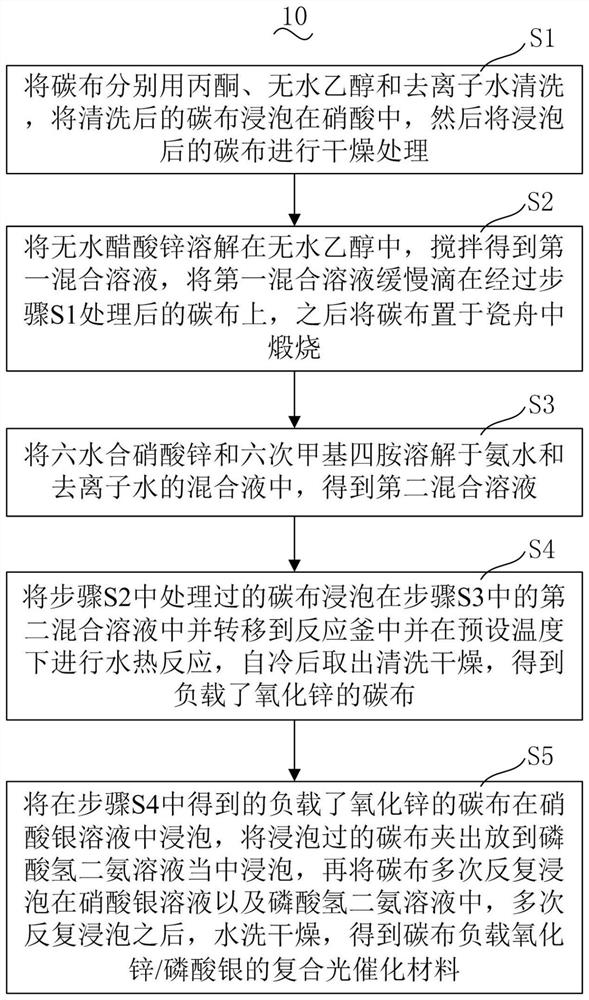

[0027] see figure 1 , the present invention provides a method for preparing a composite photocatalytic material of carbon cloth loaded with zinc oxide / silver phosphate, also known as carbon cloth loaded with ZnO / Ag 3 PO 4 The preparation method of composite photocatalyst, the preparation method of this composite photocatalytic material comprises the following steps:

[0028] Step S1, cleaning the carbon cloth with acetone, absolute ethanol and deionized water respectively, soaking the cleaned carbon cloth in nitric acid, and then drying the soaked carbon cloth.

[0029] Step S2, dissolving anhydrous zinc acetate in absolute ethanol, stirring to obtain a first mixed solution, slowly dropping the first mixed solution on the carbon cloth treated in step S1, and then arranging the carbon in a porcelain boat for calcination.

[0030] Step S3, dissolving zinc nitrate hexahydrate and hexamethylenetetramine in a mixed solution of ammonia water and deionized water to obtain a second...

Embodiment 2

[0035] The invention provides a method for preparing a carbon cloth-loaded zinc oxide / silver phosphate composite photocatalytic material, also known as carbon cloth-loaded ZnO / Ag 3 PO 4 The preparation method of composite photocatalyst, the preparation method of this composite photocatalytic material comprises the following steps:

[0036](1) Wash the carbon cloth with acetone, absolute ethanol and deionized water for 15-25 minutes, and then soak the carbon cloth in 60-65% nitric acid for 15-24 hours to improve the surface hydrophilicity and dry it;

[0037] (2) Dissolve 0.01-0.1g of anhydrous zinc acetate in 30mL of absolute ethanol, stir for 30min, slowly drop the above mixed solution on the pretreated carbon cloth, and then arrange the carbon in a porcelain boat in the air middle At Calcination at 300°C-400°C for 10min-30min.

[0038] (3) Dissolve 0.5-1g zinc nitrate hexahydrate and 0.1-0.5g hexamethylenetetramine in a mixed solution of 3-5mL ammonia water and 60-90mL de...

Embodiment 3

[0042] The invention provides a method for preparing a carbon cloth-loaded zinc oxide / silver phosphate composite photocatalytic material, also known as carbon cloth-loaded ZnO / Ag 3 PO 4 The preparation method of composite photocatalyst, the preparation method of this composite photocatalytic material comprises the following steps:

[0043] 1. Wash the carbon cloth with 20mL of acetone, 20mL of absolute ethanol and 20mL of deionized water for 20min, dry it in a drying oven at 60°C for 2h, weigh it, and then soak the cleaned carbon cloth in 20mL of nitric acid (concentration of 65%) for 24 hours to improve surface hydrophilicity and dried in a drying oven at 60° C. for 2 hours.

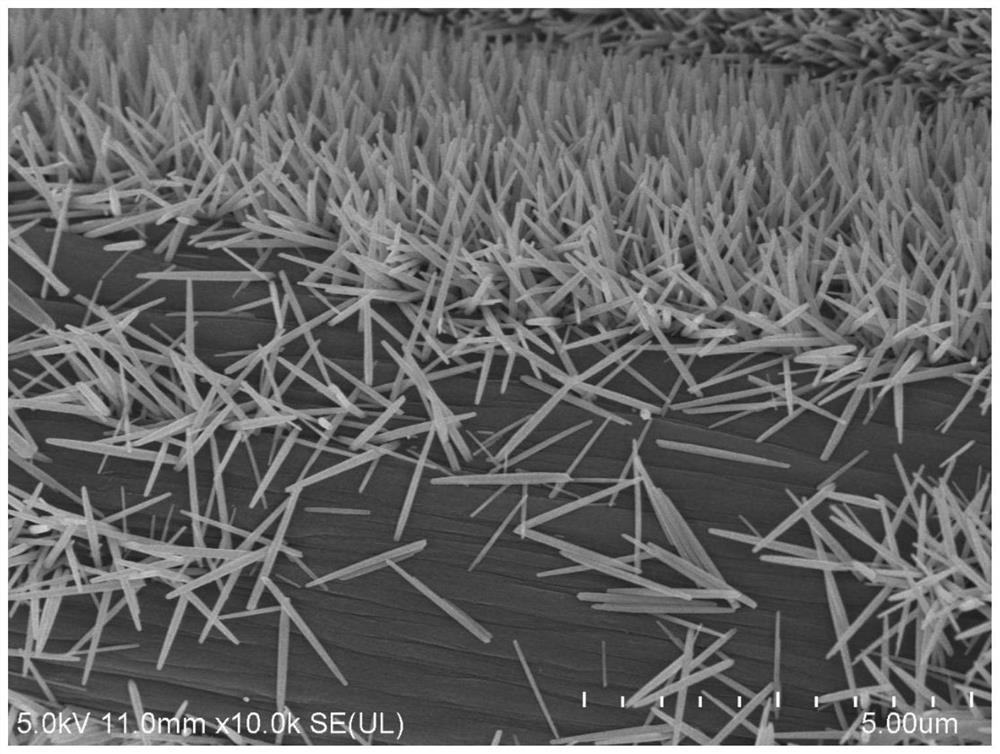

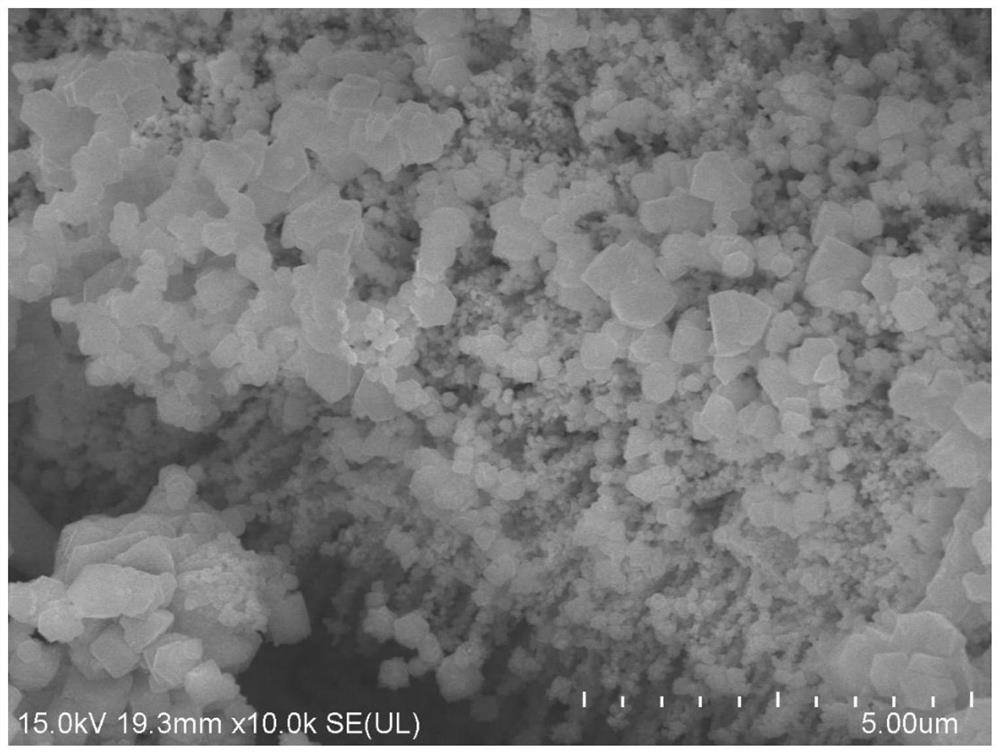

[0044] 2. Weigh 0.0329g of anhydrous zinc acetate and add it to 30mL of countless ethanol, stir until completely dissolved, slowly drop the prepared solution on the washed carbon cloth, put the soaked carbon cloth on the porcelain boat in the muffle furnace Burn in empty space at 350°C for 20 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com