Composite electrolytic paper for capacitor and preparation method thereof

A technology of electrolytic paper and capacitors, which is applied in the field of capacitors, can solve the problems of size dependence, easy short circuit, and incapable of large anode foil, etc., and achieve the effects of reducing equivalent series resistance, shortening current path, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

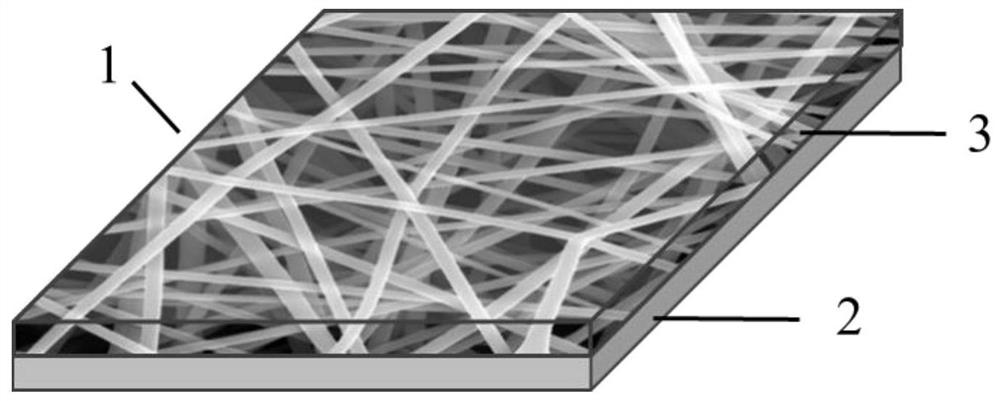

Image

Examples

preparation example Construction

[0045] 1. Preparation of spinning solution

[0046] The high molecular polymer is stirred and dissolved in the solvent at 25-100 DEG C to obtain a spinning solution with a mass fraction of 5-50%.

[0047] In some embodiments, the mass fraction of the spinning solution is 5-40%, for example: 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, and so on. Within this range, with appropriate electrospinning parameters, a porous nanofiber membrane with ideal performance indicators can be obtained.

[0048] The high molecular polymer is at least one of polyacrylonitrile, polyethylene, ethylene-vinyl acetate copolymer, polyimide and polyamide.

[0049] In some embodiments, the polymer is polyacrylonitrile.

[0050] The solvent is at least one of ethyl acetate, formic acid, acetic acid, N,N-dimethylformamide, N,N-dimethylacetamide, toluene and tetrahydrofuran.

[0051] In some embodiments, the polymer is stirred and dissolved in a solvent at 60-80° C. to obtain a spinning solution with a mass f...

Embodiment 1

[0070] Weigh 5kg of polyacrylonitrile into 45kg of N,N-dimethylformamide, fully stir and dissolve at 70°C to obtain a clarified spinning solution with a mass fraction of 10%;

[0071] Transfer the above spinning solution to the electrospinning equipment, put the N-20 type traditional electrolytic paper with a thickness of 20 μm on the collection conveyor belt, set the electrospinning parameters: the positive high voltage is 50kV, the negative high voltage is -50kV, and the spinning The distance is 20cm, the spinning solution supply rate is 1L / h, and the winding speed is 0.75m / min. With the traditional electrolytic paper as the base film, single-sided electrospinning is carried out, and the average diameter of the spun fibers is controlled to be 200nm. A composite electrolytic paper deposited with a porous nanofiber film layer was obtained, wherein the thickness of the porous nanofiber film layer was 10 μm. Finally, the composite electrolytic paper was dried and stored in a bla...

Embodiment 2

[0073] In this example, the difference from Example 1 is: the winding speed is increased to 1.5m / min, the average diameter of the spun fibers is controlled to be 200nm, and a composite electrolytic paper deposited with a porous nanofiber film layer is obtained, wherein the porous The thickness of the nanofiber film layer is 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com