Anti-seismic replacement PE pipe

A technology of outer pipeline and inner pipeline, applied in the field of PE pipeline, to achieve the effect of reducing leakage waste, reducing the difficulty of emergency treatment, and improving the ability of shock resistance and energy absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

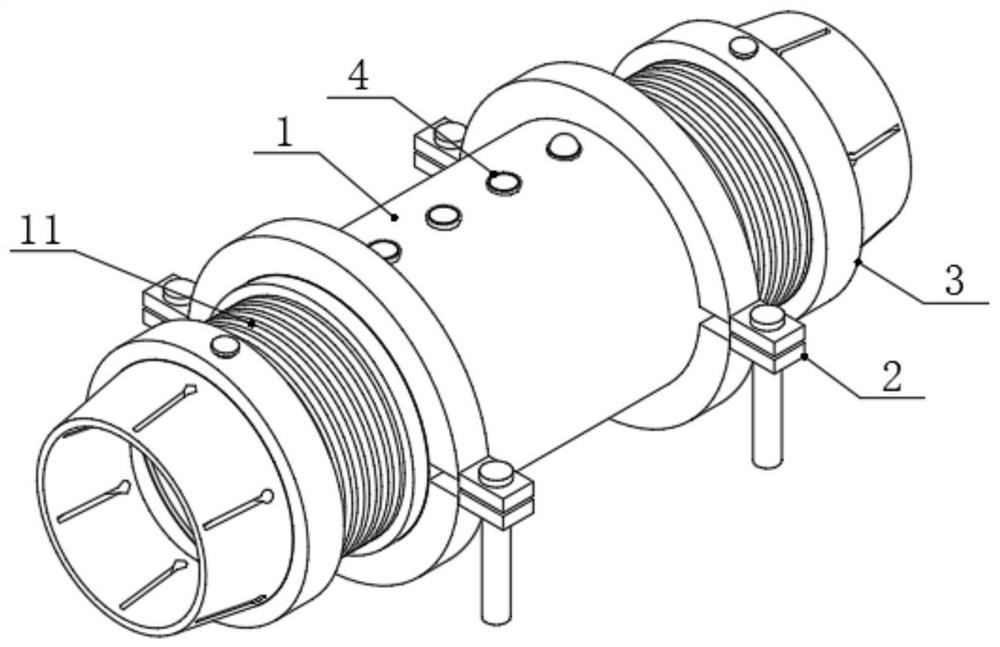

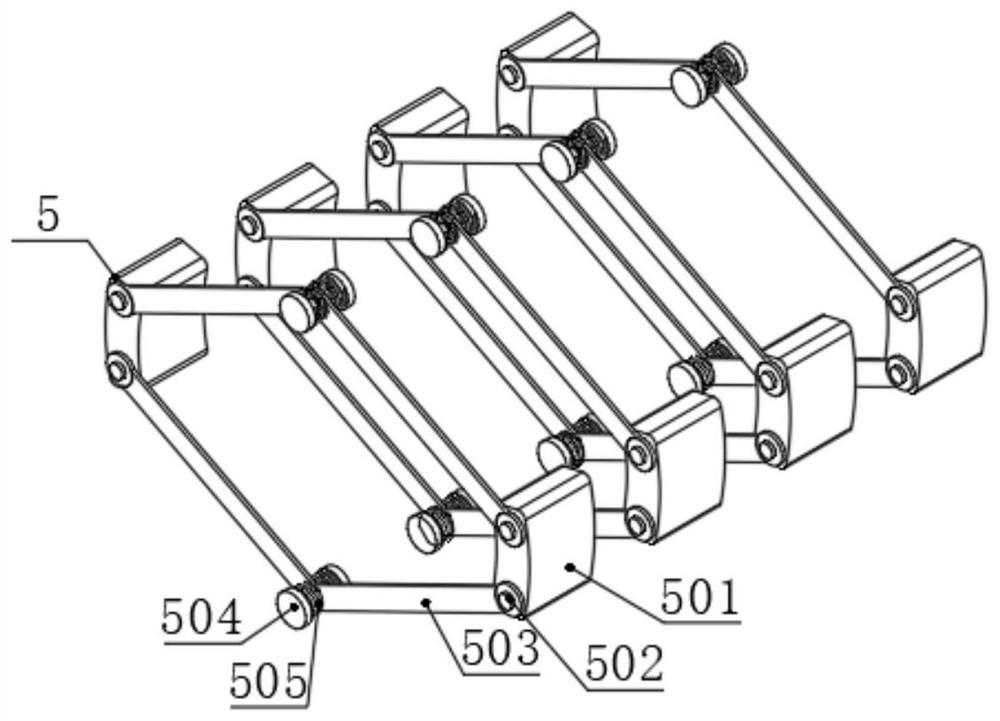

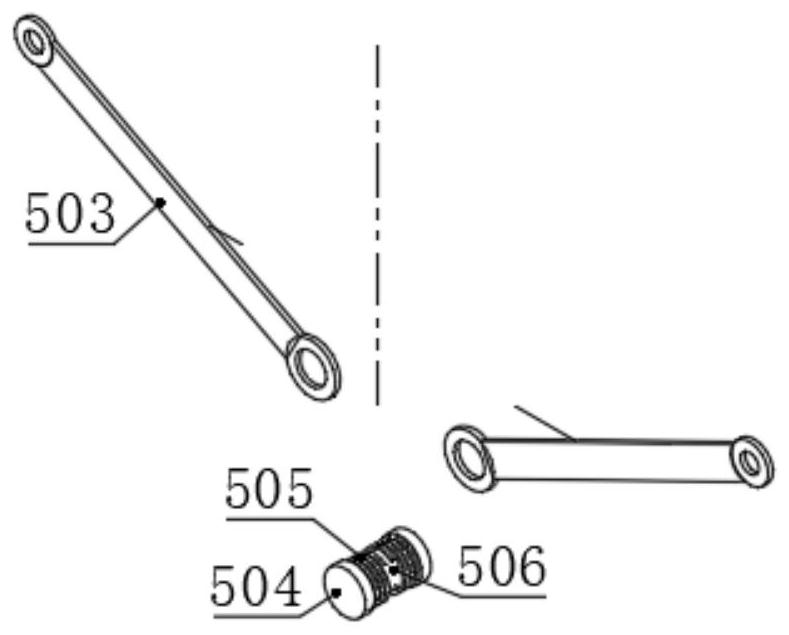

[0036] The specific implementation is: after the outer pipe 1 and the inner pipe 10 are assembled, when the water hammer effect in the inner pipe 10 or the impact of an external earthquake occurs frequency vibration, the inner pipe 10 can guide the vibration into one side through the frequency vibration of the outer surface. The connected connecting rod 503, after being deflected by force, the connecting rod 503 can pull the end hinged rod 502 to drive the non-Newtonian fluid capsule 501 to perform frequency vibration, and the non-Newtonian fluid capsule 501 can be hardened to support the impact force when it is impacted. Therefore, it is possible to realize the abutment and absorption of the axial tensile force through multiple sets of non-Newtonian fluid liquid bladders 501, and avoid lateral impact from affecting the assembly stability of the inner pipeline. After the chamber pressure increases, the pressure-sensitive membrane in the pressure collar 4 can expand and expand a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com