Material for synchronously stabilizing multiple harmful heavy metals in lead smelting slag

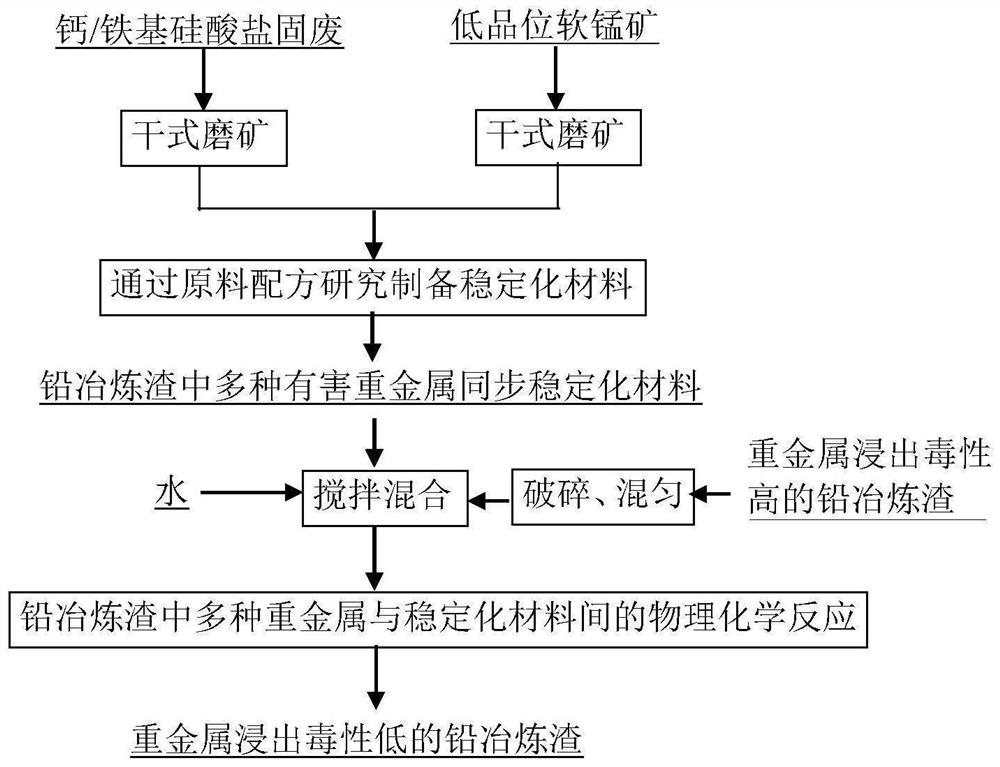

A lead smelting and heavy metal technology, which is applied in the field of synchronously stabilizing materials for various heavy metals, can solve the problems of inability to reduce lead smelting slag efficiently and synchronously, and achieve the effects of reducing leaching toxicity, wide sources, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 200g of lead smelting slag, adding 1.2% slag amount of stabilization material (mass ratio of pyrolusite to converter steel slag=8:2). Mix the stabilized material and lead smelting slag evenly, then add 20% of the total amount of water and mix evenly, put the mixed material into a polyethylene plastic tank, and stabilize at 15°C for 15 days. Then dry it in an oven at 65°C, and then use the horizontal oscillation method to measure the leaching concentrations of harmful As, Zn, Cu, and Cd to be 0.088, 0.769, 0.132, and 0.004mg / L respectively, and the pH of the leach solution is 7.76, and the leach toxicity meets the emission requirements. Require.

Embodiment 2

[0042] Lead smelting slag 200g, add 1.2% slag amount of stabilization materials (mass ratio of pyrolusite to fly ash = 8:2). Mix the stabilized material and lead smelting slag evenly, add 25% of the total amount of water to mix evenly, put the mixed material into a polyethylene plastic tank, and stabilize at an ambient temperature of 20°C for 20 days. Then dry it in an oven at 65°C, and then use the horizontal oscillation method to measure the leaching toxicity of As, Zn, Cu, and Cd to be 0.086, 0.871, 0.141, and 0.003 mg / L respectively, and the pH of the leachate is 7.65, which meets the emission requirements. .

Embodiment 3

[0044] 200g of lead smelting slag, adding 1.5% slag amount of stabilization material (mass ratio of pyrolusite to ferronickel slag=6:4). Mix the stabilized material and lead smelting slag evenly, add 15% of the total amount of water to mix evenly, put the mixed material into a polyethylene plastic tank, and stabilize at 25°C for 40d. Then it was dried in an oven at 65°C. The leaching toxicity of As, Zn, Cu, and Cd measured by the horizontal oscillation method were 0.076, 0.518, 0.132, and 0.004mg / L, respectively, and the pH of the leachate was 7.24. The leaching toxicity met the emission requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com