Flavored soybean paste and preparation method thereof

A soybean paste and flavor technology, applied in the field of condiments, can solve the problems that low-salt soybean paste cannot meet consumers' taste, nutrition and safety requirements, and achieve the effects of preventing vascular terminal constriction, prolonging shelf life, and being easy to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

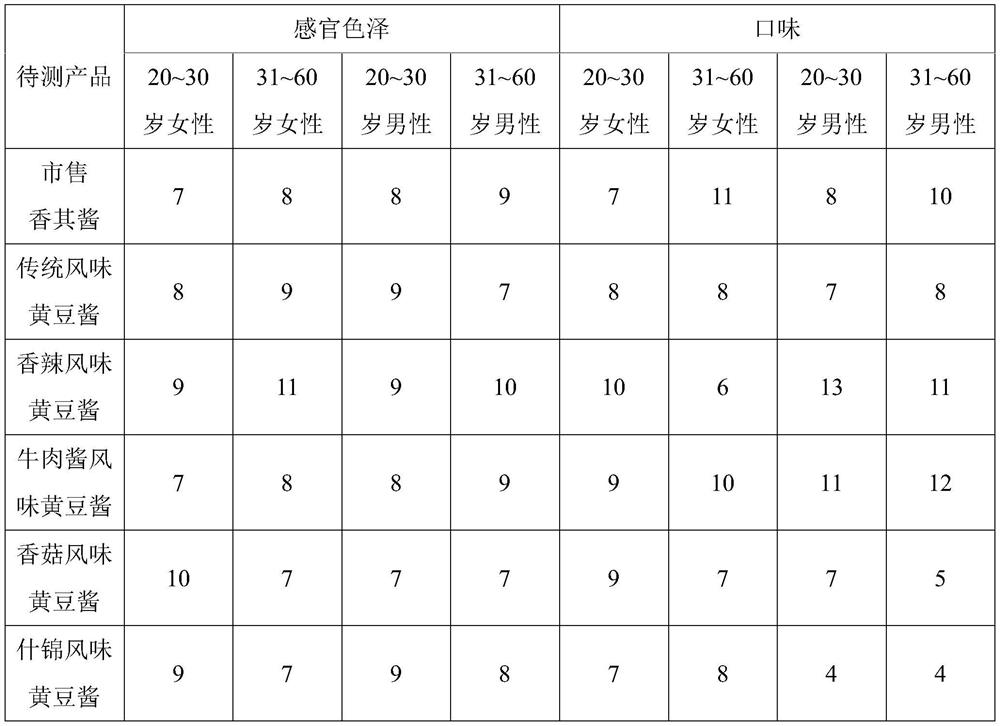

Examples

Embodiment 1

[0043] This example provides a traditional flavor soybean paste and its preparation method.

[0044] The traditional flavor soybean paste of this embodiment includes the following components in parts by mass: 5 parts of insoluble soybean dietary fiber powder, 50 parts of soybean paste powder containing ACE inhibitory peptide, 10 parts of probiotic enzyme powder, and 30 parts of seasoning powder.

[0045] The preparation method of the traditional flavor soybean paste of the present embodiment comprises the steps:

[0046] Step 1, soybean pretreatment to prepare insoluble soybean dietary fiber and soybean protein powder:

[0047] Dry soybeans at 70°C to constant weight, crush them through a 100-mesh sieve to obtain soybean powder; add water and cellulase to soybean powder at a mass-volume ratio of 1g:50mL:0.5mL, and the enzyme activity of cellulase is 3U / mL, fully stirred and mixed with ultrasonic extraction, the power is 300W, the extraction temperature is 45°C, after ultraso...

Embodiment 2

[0064] This example provides a spicy soybean paste and a preparation method thereof.

[0065] The spicy flavor soybean paste of this embodiment comprises the following components by mass: 5 parts of insoluble soybean dietary fiber powder, 50 parts of soybean paste powder containing ACE inhibitory peptide, 10 parts of probiotic ferment microcapsules, 30 parts of seasoning powder and chili powder 5 servings.

[0066] The preparation method of the spicy flavor soybean paste of the present embodiment comprises the steps:

[0067] Step 1, soybean pretreatment to prepare insoluble soybean dietary fiber and soybean protein powder:

[0068] Dry soybeans at 60°C to constant weight, crush and pass through an 80-mesh sieve to obtain soybean powder; add water and cellulase to soybean powder at a mass-volume ratio of 1g:70mL:1mL, and the enzyme activity of cellulase is 3U / mL , fully stirred and mixed for ultrasonic extraction, the power is 400W, the extraction temperature is 50°C, after ...

Embodiment 3

[0087] This embodiment provides a soybean paste with a beef paste flavor and a preparation method thereof.

[0088] The present embodiment beef paste flavor soybean paste comprises the following components by mass: 6 parts of insoluble soybean dietary fiber powder, 45 parts of soybean paste powder containing ACE inhibitory peptide, 10 parts of probiotic enzyme powder, 20 parts of seasoning powder, dehydrated beef grains 6 parts, 1 part dehydrated diced carrot, 1 part dehydrated wolfberry, 1 part dehydrated diced fungus and 1 part fried sesame seed.

[0089] The preparation method of the present embodiment beef paste local flavor soybean paste comprises the steps:

[0090] Step 1, soybean pretreatment to prepare insoluble soybean dietary fiber and soybean protein powder:

[0091] Dry soybeans at 70°C to constant weight, crush them through an 80-mesh sieve to obtain soybean powder; add water and cellulase to soybean powder at a mass-volume ratio of 1g:50mL:3mL, and the enzyme a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com