Method for regulating and controlling structural characteristics and fiber structure of plant protein in high-moisture extrusion process

A plant protein and extrusion process technology is applied in the field of regulating plant protein structure properties and fiber structure during high-moisture extrusion process, and achieves the effects of simple production process, rich fiber and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

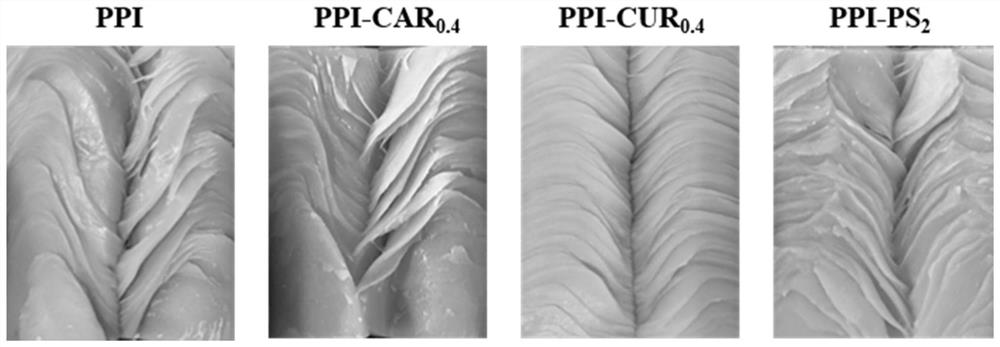

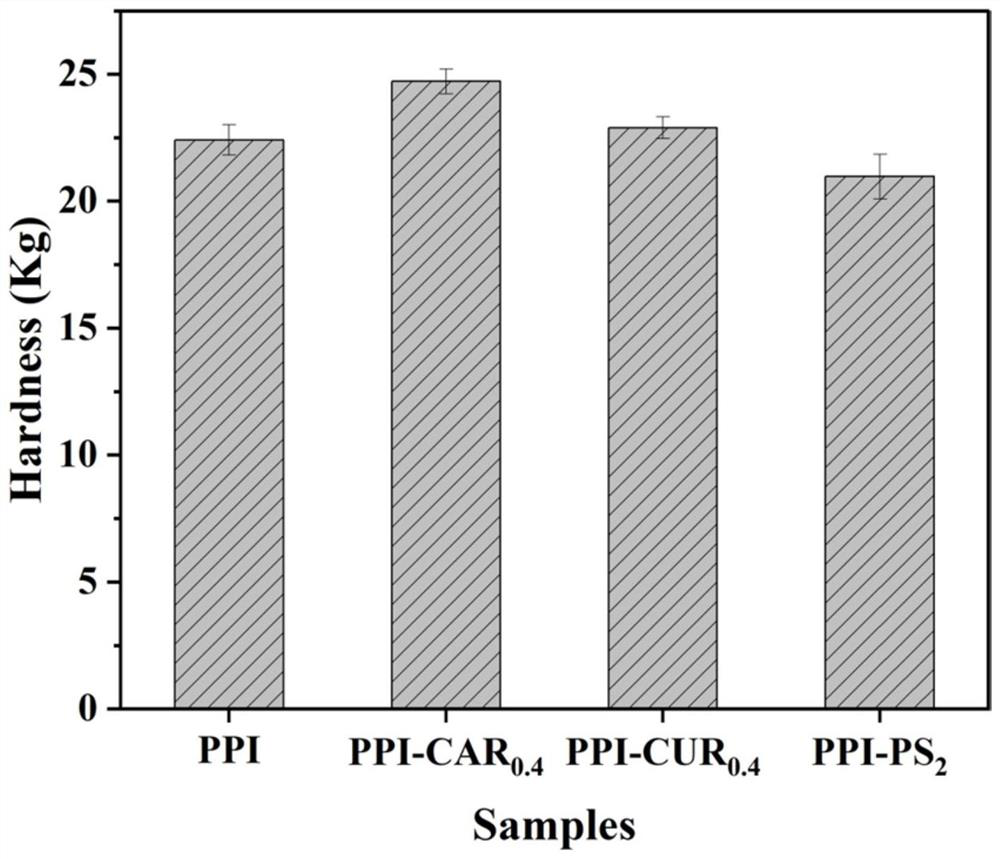

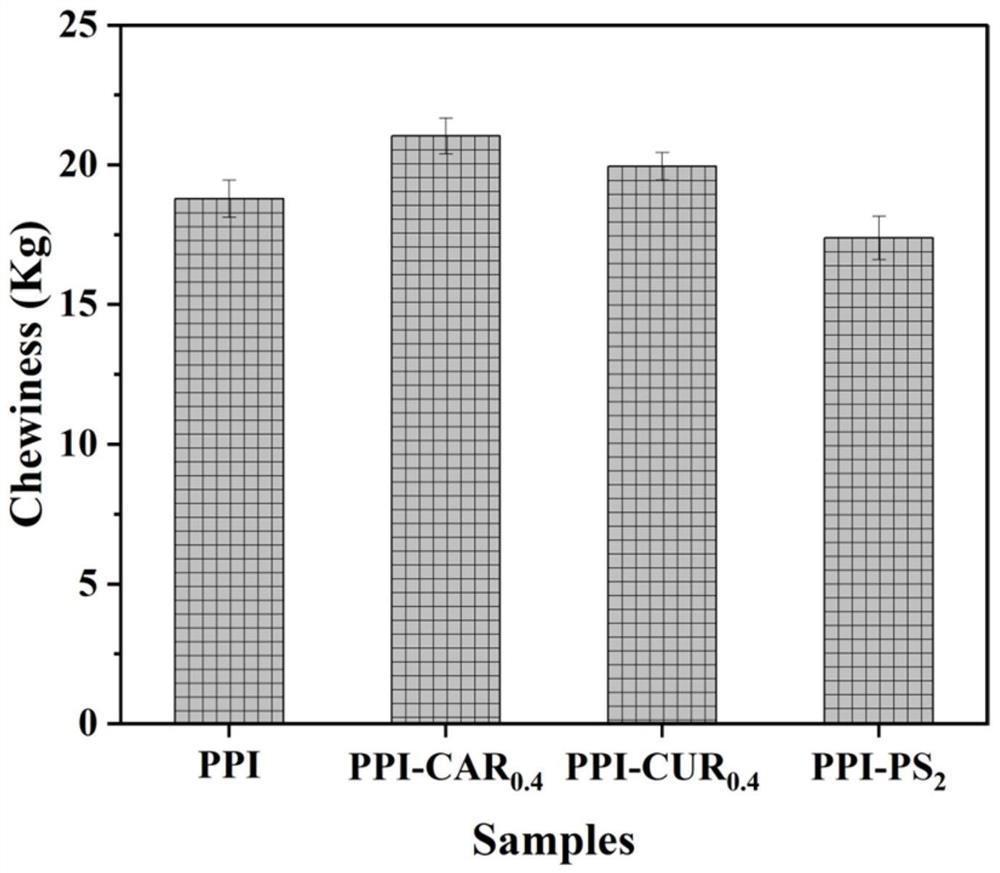

Embodiment 1

[0042] Figure 8 Schematic diagram of the process of regulating the structural properties and fiber structure of plant proteins for the high-moisture extrusion process. The specific steps include:

[0043] 1) Carrageenan is added to the pea protein isolate for blending, and the addition amount is 0.4wt%.

[0044] 2) High-moisture extrusion experiment: high-moisture extrusion was performed on the blend of pea protein isolate and carrageenan. The operating parameters of the twin-screw extruder are set as follows: the moisture content of the material is 55%, the screw speed is fixed at 175rpm, and the feeding speed of the feeder is 7g / min. In the 8 zones from the feed section to the die mouth section, The barrel temperature settings were 40°C, 60°C, 90°C, 120°C, 160°C, 160°C, 160°C and 160°C, respectively. The long cooling mold is kept at 70°C by water circulation temperature control.

[0045]3) Collect the extrudate and cool. Put 200g of the extruded product into the cooking...

Embodiment 2

[0047] 1) Add curdlan gum to the pea protein isolate for blending, and the addition amount is 0.4wt%.

[0048] 2) High-moisture extrusion experiment: high-moisture extrusion was performed on the blend of pea protein isolate and curdlan gum. The operating parameters of the twin-screw extruder are set as follows: the moisture content of the material is 55%, the screw speed is fixed at 175rpm, and the feeding speed of the feeder is 7g / min. In the 8 zones from the feed section to the die mouth section, The barrel temperature settings were 40°C, 60°C, 90°C, 120°C, 160°C, 160°C, 160°C and 160°C, respectively. The long cooling mold is kept at 70°C by water circulation temperature control.

[0049] 3) Collect the extrudate and cool. Put 200g of the extruded product into the cooking machine, chop, mix and shred, add 100g of cabbage, 5g of salt, 6g of sugar, 10g of onion, 15g of leek, 5g of five-spice powder, 10g of sesame oil, 15g of soy sauce, 25g of beef extract, Continue chopping...

Embodiment 3

[0051] 1) Add potato starch to pea protein isolate for blending, the addition amount is 2wt%.

[0052] 2) High-moisture extrusion experiment: high-moisture extrusion was performed on the blend of pea protein isolate and curdlan gum. The operating parameters of the twin-screw extruder are set as follows: the moisture content of the material is 55%, the screw speed is fixed at 175rpm, and the feeding speed of the feeder is 7g / min. In the 8 zones from the feed section to the die mouth section, The barrel temperature settings were 40°C, 60°C, 90°C, 120°C, 160°C, 160°C, 160°C and 160°C, respectively. The long cooling mold is kept at 70°C by water circulation temperature control.

[0053] 3) Collect the extrudate and cool. Put 200g of the extruded product into the cooking machine, chop, mix and shred, add 100g of cabbage, 5g of salt, 6g of sugar, 10g of onion, 15g of leek, 5g of five-spice powder, 10g of sesame oil, 15g of soy sauce, 25g of beef extract, Continue chopping and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com