Bottom-surface integrated shell powder coating and preparation method thereof

A shell powder, integrated technology, used in lime coatings, fire-resistant coatings, coatings, etc., can solve the problems of integration, the coating cannot be used as the bottom surface, etc., to reduce pollution, improve wear resistance and anti-cracking performance, and improve waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

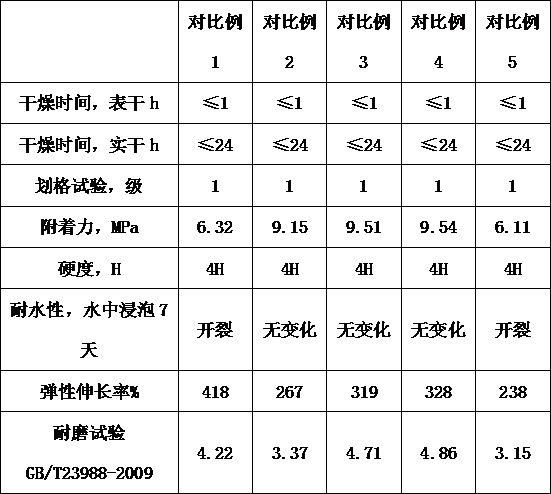

Examples

Embodiment 1

[0016] An integrated shell powder coating for the bottom surface, which is composed of the following ingredients in weight percentage: 18% high-temperature calcined shell powder, 12% lime calcium, 3.5% kaolin, 1.8% talcum powder, 3.2% latex powder, 1.7% polyvinyl alcohol, titanium dioxide 4.2%, 1.5% cellulose, 35% quartz sand, 1.2% water reducing agent, 2.5% thickening lubricant, 1.5% water resistant agent, 1.2% bentonite, 0.7% propanol ether, 5.5% vitrified microbeads, three-dimensional porous Double cross-linked polyaniline / graphene composite xerogel 0.12% and white cement the rest.

[0017] The latex powder is vinyl acetate / ethylene tertiary carbonate copolymer.

[0018] The bentonite is iron-silicon modified bentonite.

[0019] The three-dimensional porous double-crosslinked polyaniline / graphene composite xerogel is a three-dimensional porous structure composed of a graphene skeleton, graphene and polyaniline in the form of double crosslinks. gel. For the specific prepa...

Embodiment 2

[0022] An integrated shell powder coating for the bottom surface, which is composed of the following ingredients in weight percentage: 16% high-temperature calcined shell powder, 12% lime calcium, 2.5% kaolin, 1.8% talcum powder, 3.2% latex powder, 1.8% polyvinyl alcohol, titanium dioxide 4.5%, cellulose 1.2%, quartz sand 38%, water reducing agent 1.2%, thickening lubricant 2.1%, water resistance agent 1.1%, bentonite 1.4%, propanol ether 0.7%, vitrified microbeads 5.1%, three-dimensional porous Double cross-linked polyaniline / graphene composite xerogel 0.08% and white cement the rest.

[0023] The latex powder is vinyl acetate / ethylene tertiary carbonate copolymer.

[0024] The bentonite is iron-silicon modified bentonite.

[0025] The three-dimensional porous double-crosslinked polyaniline / graphene composite xerogel is a three-dimensional porous structure composed of a graphene skeleton, graphene and polyaniline in the form of double crosslinks. gel. For the specific prep...

Embodiment 3

[0028] An integrated shell powder coating for the bottom surface, which is composed of the following ingredients in weight percentage: high-temperature calcined shell powder 17%, ash calcium 13%, kaolin 2.5%, talcum powder 1.7%, latex powder 2.2%, polyvinyl alcohol 1.1%, titanium dioxide 3.8%, 1.1% cellulose, 32% quartz sand, 1.5% water reducing agent, 2.5% thickening lubricant, 1.8% water resistance agent, 1.2% bentonite, 0.7% propanol ether, 4.4% vitrified microbeads, three-dimensional porous Double cross-linked polyaniline / graphene composite xerogel 0.09% and white cement the rest.

[0029] The latex powder is vinyl acetate / ethylene tertiary carbonate copolymer.

[0030] The bentonite is iron-silicon modified bentonite.

[0031] The three-dimensional porous double-crosslinked polyaniline / graphene composite xerogel is a three-dimensional porous structure composed of a graphene skeleton, graphene and polyaniline in the form of double crosslinks. gel. For the specific prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com