Walnut shell breaking and kernel taking method and device based on grinding-extruding synergistic effect

A walnut and grinding technology, which is applied in the field of methods and devices for walnut shell breaking and kernel extraction to achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following in conjunction with the accompanying drawings will be described in detail in a particular embodiment of the present invention.

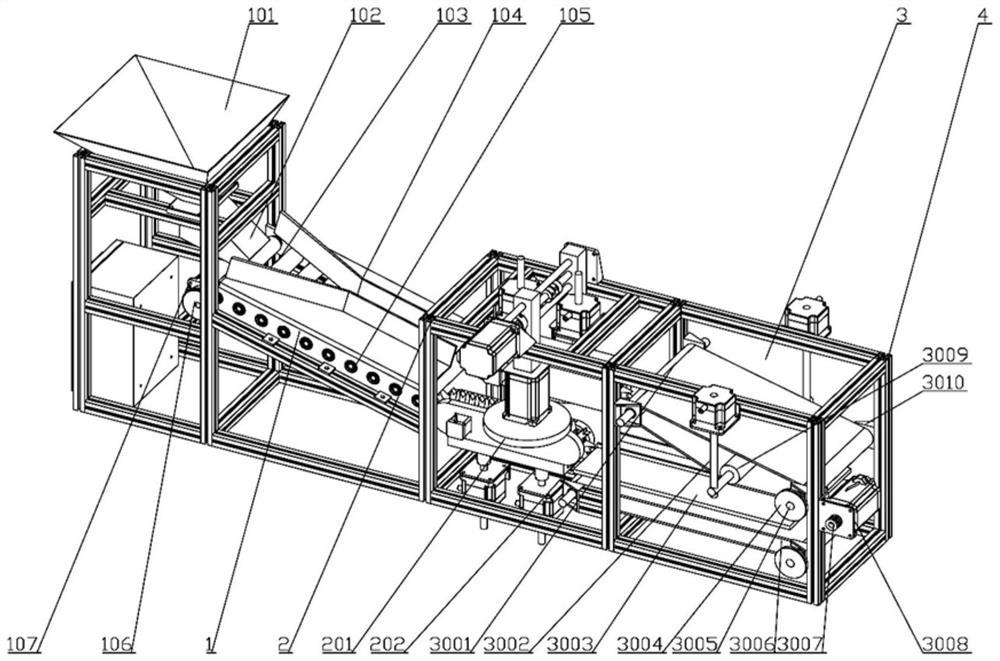

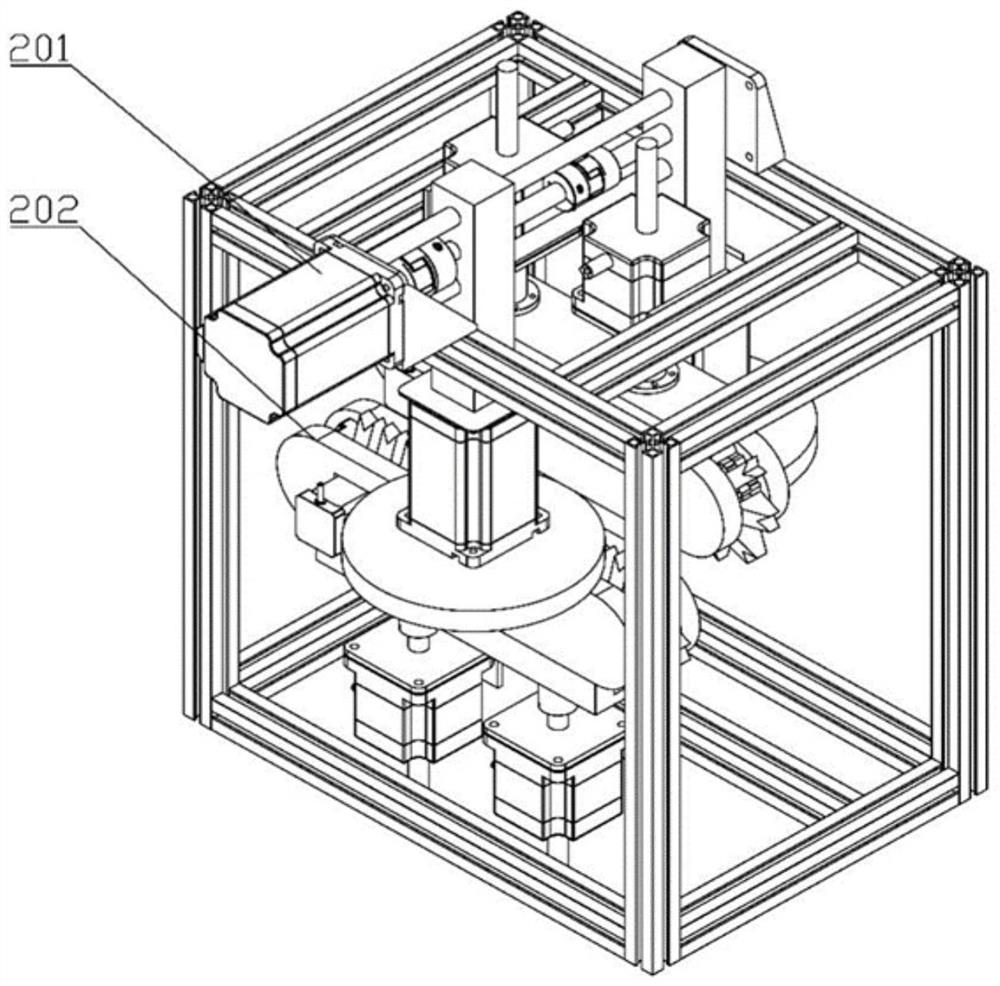

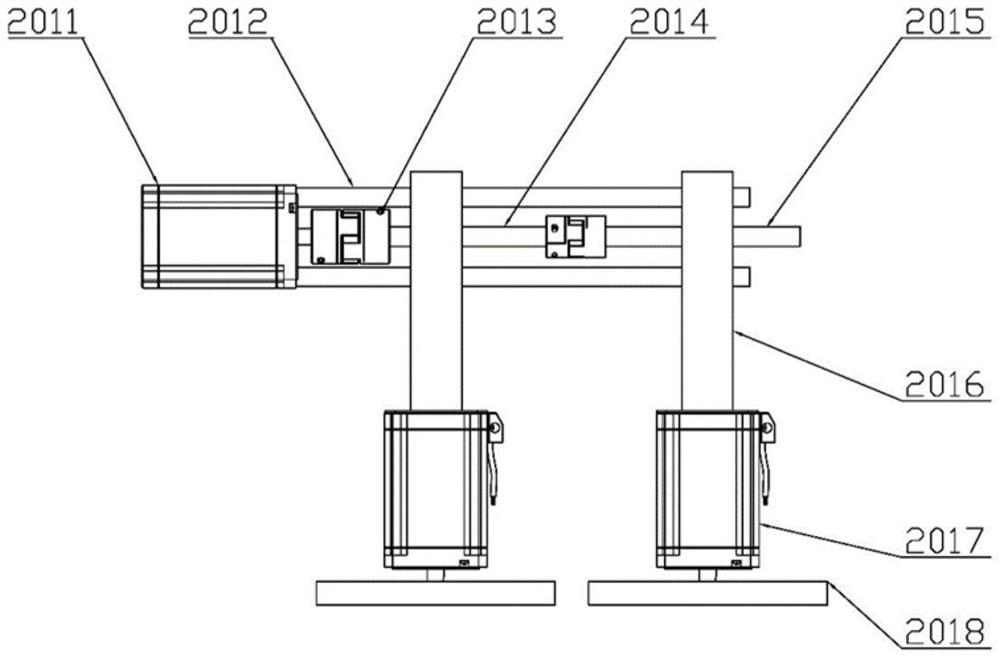

[0024] as Figures 1 to 4 As shown, a walnut shell breaking method and apparatus based on grinding-extrusion synergy, including attitude adjustment conveying mechanism (1), clamping grinding mechanism (2), kneading extrusion shell breaking mechanism (3), frame (4); attitude adjustment conveying mechanism (1) including hopper (101), deflector (102), roller (103), guide plate (104), bearing (105), gear (106), stepper motor (107); clamping grinding mechanism (2) including feed grinding device (201) , Variable clamping device (202); Feed grinding device (201) including stepper motor (2011), support rod (2012), coupling (2013), orthodontic transmission screw (2014), reverse gear drive screw (2015), slider (2016), stepper motor (2017), grinding wheel (2018); variable clamping components (202) including screw stepper motor (2021), stepper mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com