A method for preparing a large-area radioactive source

A radioactive source and large-area technology, applied in the direction of the plating tank, can solve the problems of low plating efficiency, low efficiency, and large waste liquid, and achieve the effect of keeping the parallelism unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a large-area radioactive source, the method comprising the steps of:

[0039] 1) Perform pre-plating treatment on the plated sheet

[0040] Utilize Na 2 CO 3Clean the surface of the plated sheet with the solution to remove the oil layer; then clean the surface with tap water, deionized water and isopropanol respectively, and dry it for later use.

[0041] 2) Configure spare plating solution

[0042] First configure a nitric acid solution with a concentration of 0.01-0.05mol / L, and add it to the isopropanol matrix as a spare plating solution;

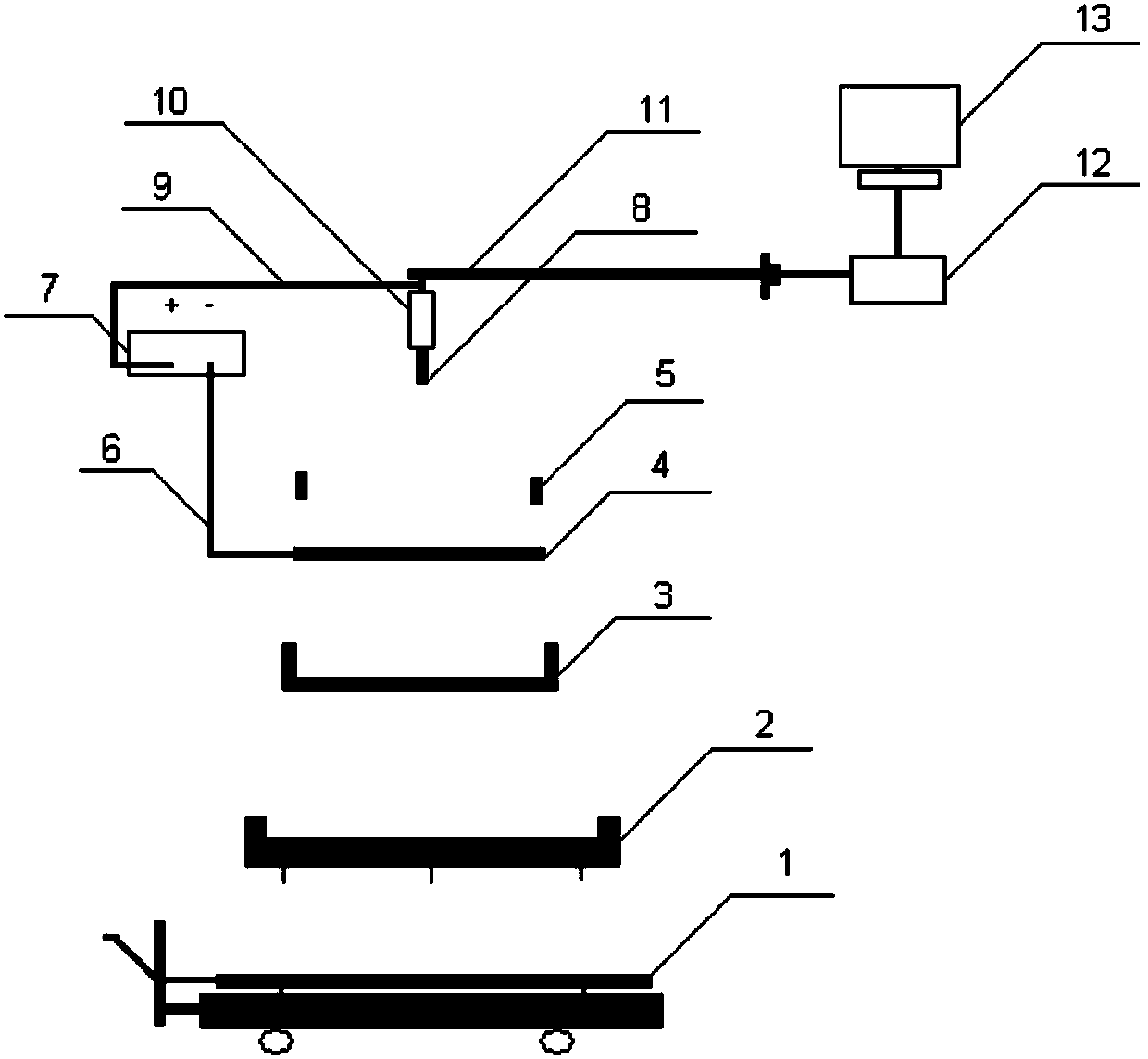

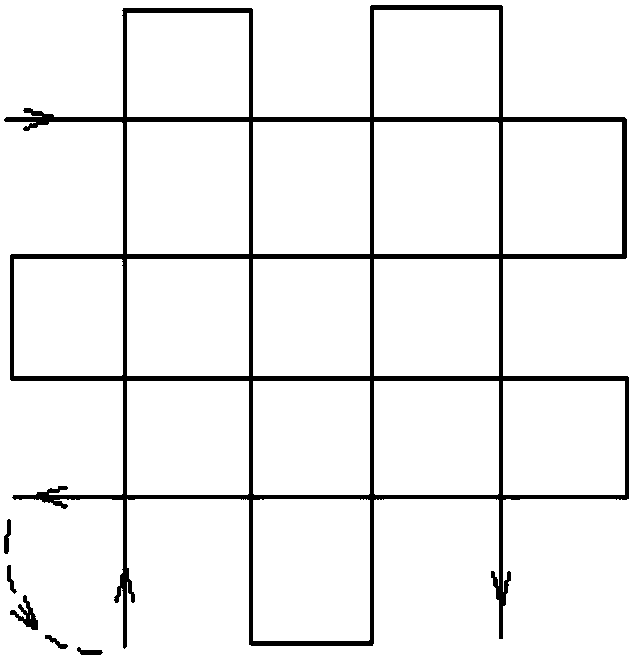

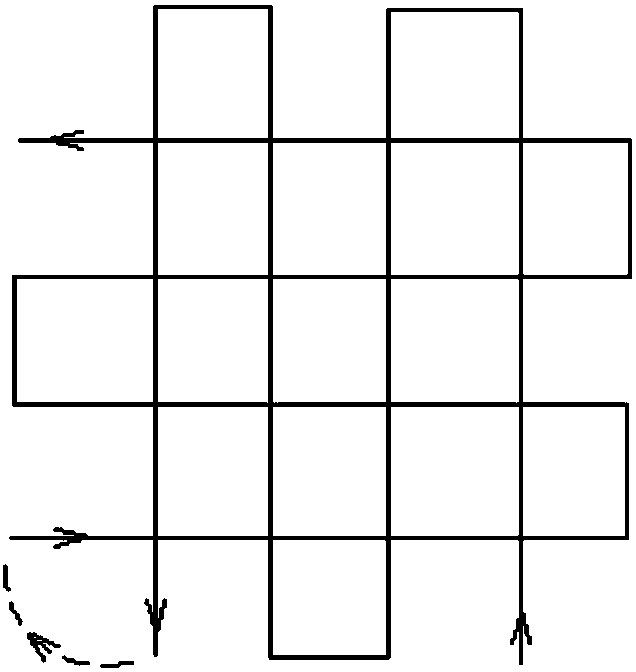

[0043] 3) A large-area radioactive source is prepared by a large-area radioactive source preparation device, wherein the preparation device includes a lifting platform car 1, an adjusting platform 2, a plating tank 3, a plating sheet 4, a plating solution protection frame 5, and a Sanheng multi-purpose electrophoresis instrument Power supply 7, plated pen 8, gauge block, plated pen support 10, two-dimens...

Embodiment 2

[0054] Different from Example 1, the type of nuclide to be plated is 90 Sr- 90 Y, set the power supply voltage to 600V and the current to 20mA.

Embodiment 3

[0056] Different from Example 1, the type of nuclide to be plated is 204 Tl, set the voltage value to 700V, and the current value to 25mA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com