A construction method of high-altitude and large-span cast-in-situ multi-arch aqueduct support formwork system

A construction method and technology for supporting formwork, which are applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of high rental costs, large steel usage, and inability to achieve elevation control, so as to achieve low rental costs and reduced usage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

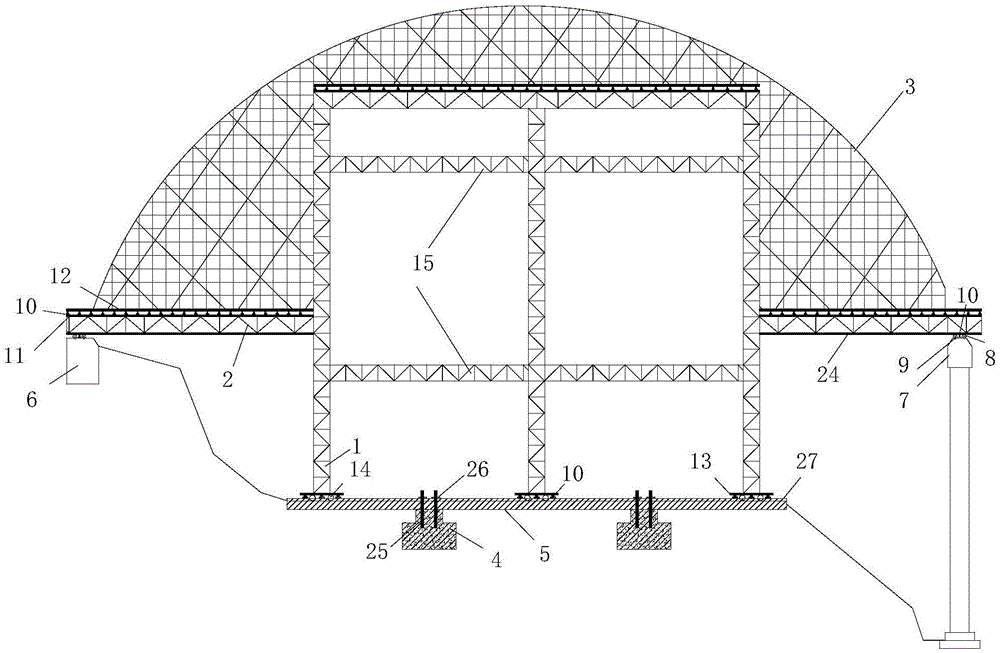

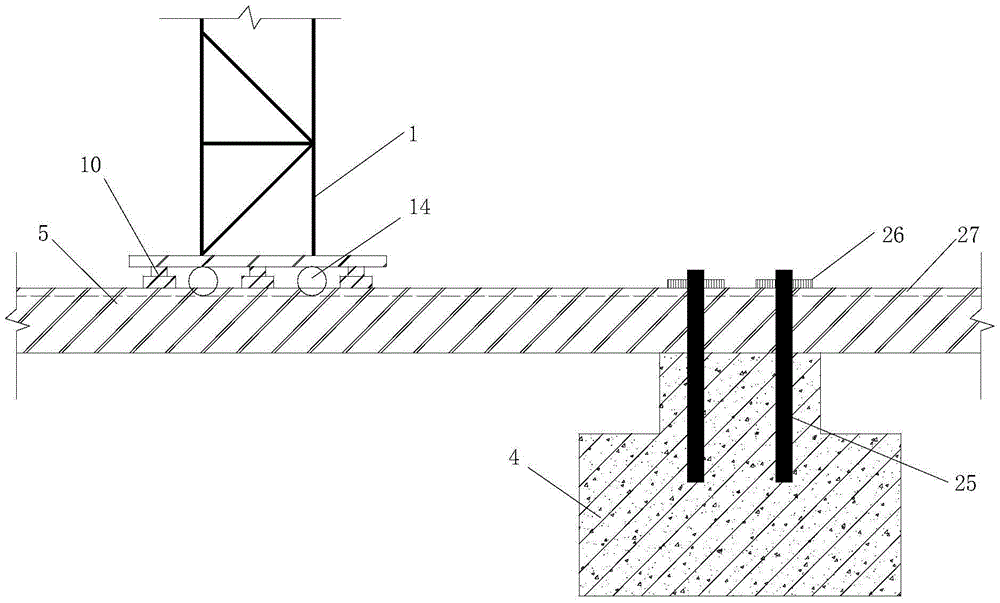

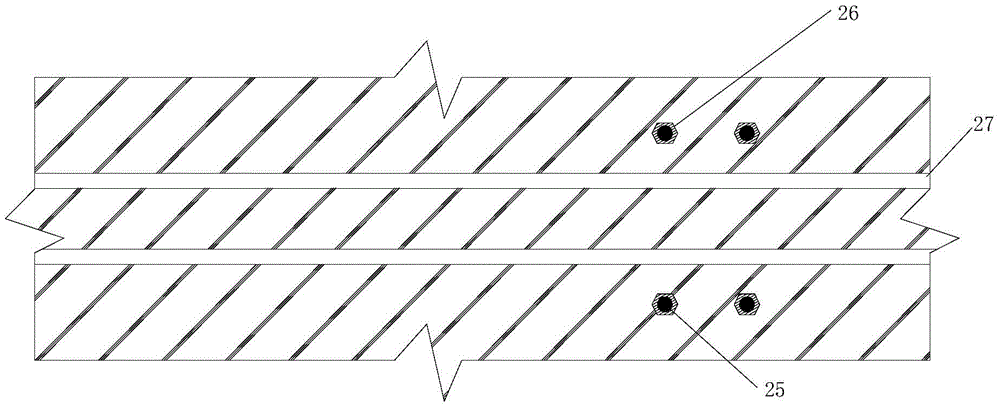

[0036] figure 1 It is a structural schematic diagram of the high-altitude and large-span cast-in-situ multi-arch aqueduct supporting formwork of the present invention. refer to figure 1 As shown, the high-altitude large-span cast-in-situ multi-arch aqueduct supporting formwork system of the present invention mainly includes a steel support 1, a military beam 2, a bowl buckle scaffold 3 and a connecting beam 15.

[0037] Before erecting the high-altitude large-span cast-in-situ multi-arch aquedu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com