Aqueous zinc ion battery electrolyte and battery

A technology of zinc-ion batteries and electrolytes, applied in aqueous electrolytes, electrolytes, secondary batteries, etc., can solve problems such as consumption, damage to battery cycle life, shelf life and capacity retention, zinc electrode corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]The present embodiment provides a kind of preparation method of the electrolytic solution of water system zinc ion battery, and its composition is as follows: zinc sulfate, sodium glutamate and solvent water. The zinc sulfate of 0.2mol and the sodium glutamate of 0.01mol are dissolved in deionized water, and are configured into 100mL electrolyte containing 2mol / L zinc sulfate and 0.1mol / L sodium glutamate.

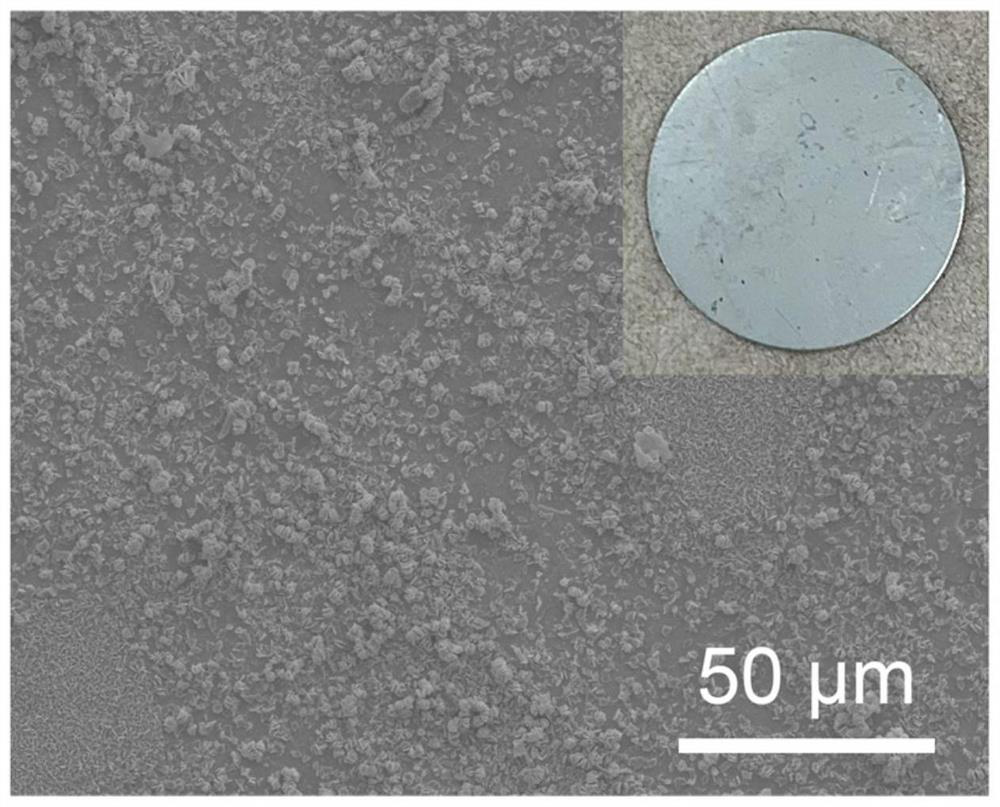

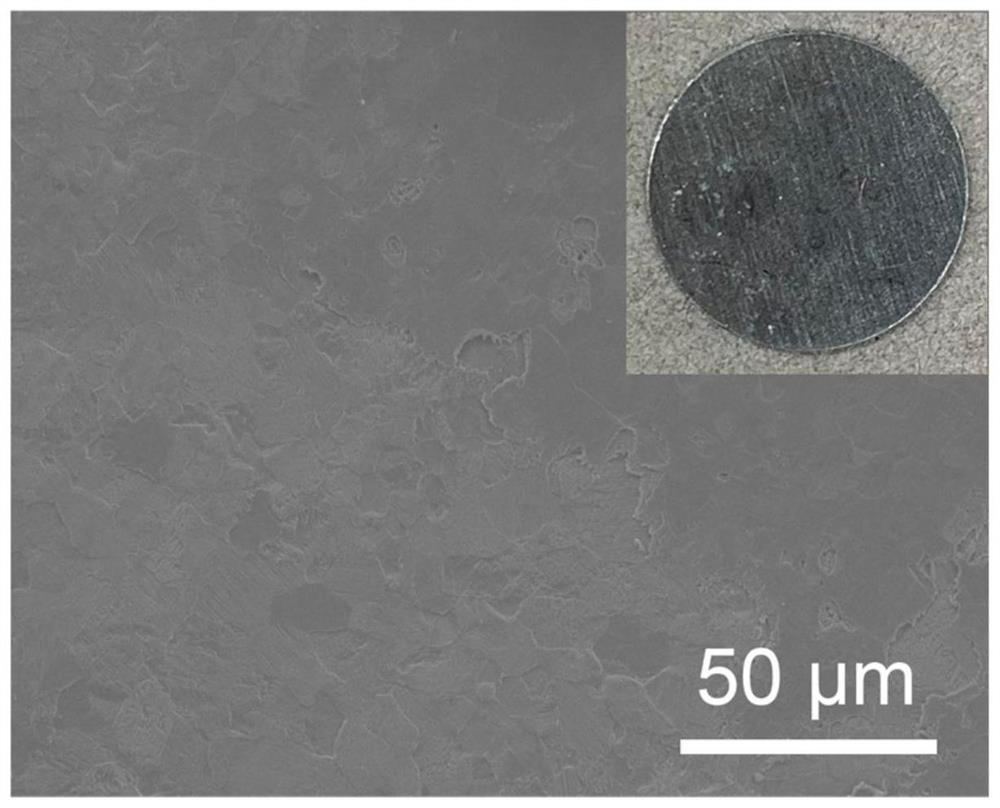

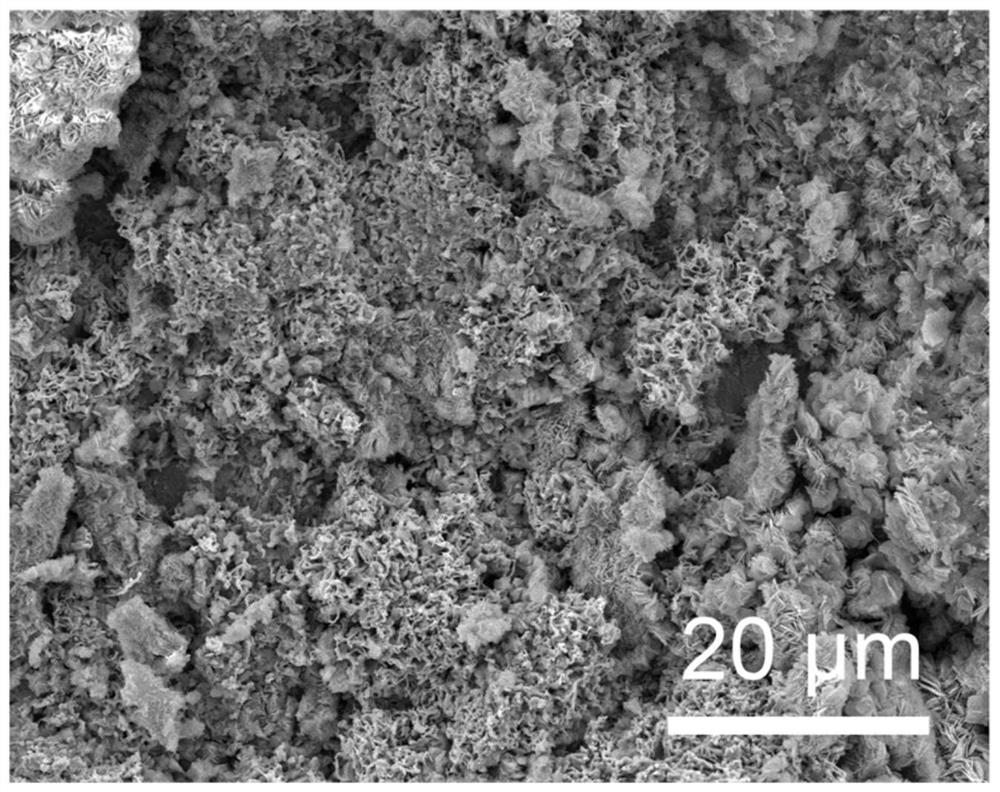

[0039] Soak the zinc flakes in the electrolyte prepared in this example to observe the corrosion status of the zinc flakes. After soaking for 21 days, the morphology of the surface of the zinc flakes is shown in Figure 1(b). The zinc flakes remain bright and have no by-products, reflecting that the chemical stability of metal zinc in the electrolyte of this example is better. Apply the electrolyte of this example to a zinc-zinc symmetrical button cell, at 5mA / cm 2 The current density and 5mAh / cm 2 The deposition capacity was charged and discharged, and the depositi...

Embodiment 2

[0046] This embodiment provides an aqueous zinc-ion battery, and the positive electrode active material adopts α-MnO 2 . Its preparation method comprises the following steps:

[0047] (1) Preparation of electrolyte: Dissolve 0.2 mol of zinc sulfate and 0.01 mol of sodium glutamate in deionized water to prepare 100 mL of a mixed solution containing 2 mol / L zinc sulfate and 0.1 mol / L of sodium glutamate; Then add 0.02 mol of manganese sulfate into the mixed solution, stir until completely dissolved, and obtain the target electrolyte.

[0048] (2) Preparation of positive electrode sheet:

[0049] α-MnO 2 , Ketjen Black and polytetrafluoroethylene (PTFE) were mixed in a mass ratio of 7:2:1, and isopropanol was used as a solvent. After grinding evenly, they were rolled onto a stainless steel mesh and dried at 70°C for 12 hours to obtain a pole piece with a loading capacity of 3~4mg / cm 2 .

[0050] (3) Assembly of aqueous zinc-ion battery:

[0051] The aqueous zinc-ion batter...

Embodiment 3

[0058] This embodiment provides an aqueous zinc-ion battery, and the positive electrode active material is TCNQ@PPy. Its preparation method comprises the following steps:

[0059] (1) Electrolyte preparation: Dissolve 0.2mol of zinc chloride and 0.01mol of sodium glutamate in deionized water to prepare 100mL of 2mol / L zinc chloride and 0.1mol / L of sodium glutamate electrolyte.

[0060] (2) Polypyrrole coating of TCNQ

[0061] 0.2 g of TCNQ was dispersed in 50 mL of 0.3 M polyvinylpyrrolidone aqueous solution and stirred at room temperature for 1 hour. After centrifugation, disperse in 50mL water, add pyrrole monomer and stir for 0.5 hours, then add ammonium persulfate. Wherein, the mass ratio of TCNQ and pyrrole monomer is 8:1, and the mol ratio of pyrrole and sodium persulfate is 1:1. The solution was stirred at 0 °C for 12 hours. The resulting precipitate was collected by centrifugation, washed with water several times and dried at 70 °C to obtain the TCNQ@PPy material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com