Ultrahigh-pressure air inlet oxygen-enriched combustion two-stroke internal combustion engine

A two-stroke internal combustion engine, oxygen-enriched combustion technology, applied in combustion engines, internal combustion piston engines, adding non-fuel substances to fuel, etc., can solve the problems of incomplete exhaust gas removal, large emission pollution, and many unburned products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

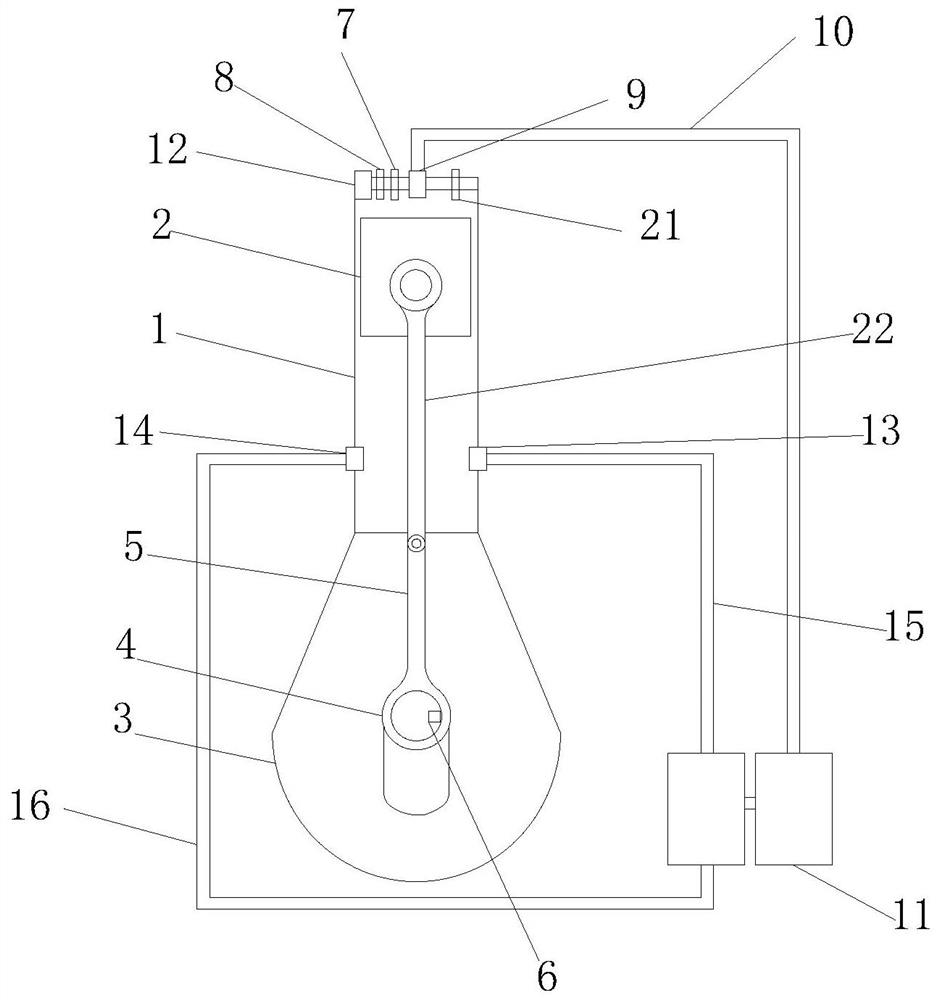

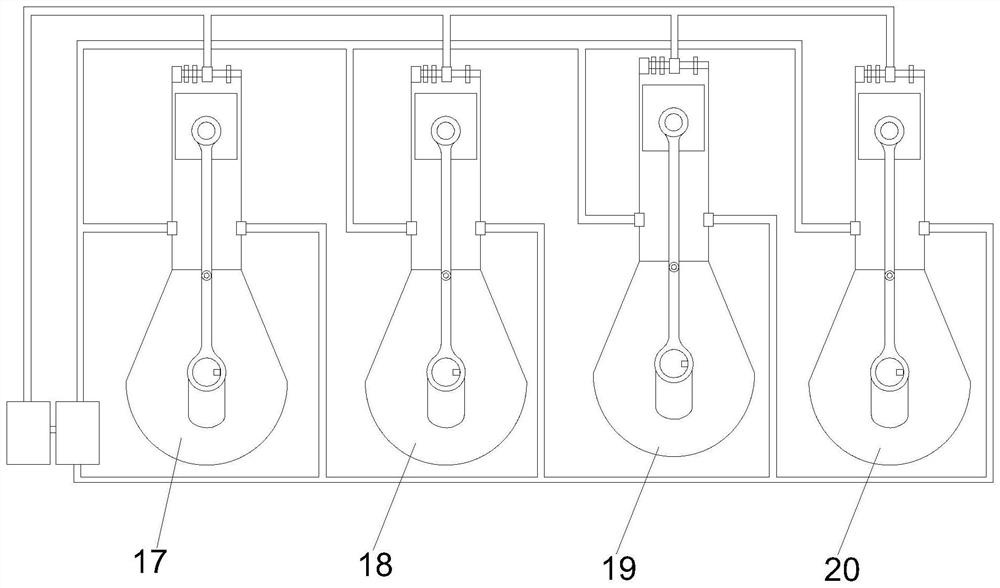

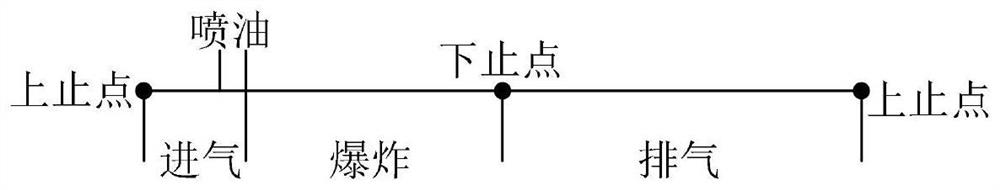

[0034] Please refer to Figure 1-Figure 3 ,Such as figure 1 It is a structural schematic diagram of an ultra-high pressure intake air oxygen-enriched combustion two-stroke internal combustion engine according to an embodiment of the present invention; figure 2 It is a schematic diagram of the connection structure of multiple internal combustion engine bodies in the embodiment of the present invention; image 3 It is a schematic diagram of the working principle of the internal combustion engine body in the embodiment of the present invention;

[0035] In the embodiment of the present application, an ultra-high pressure intake air oxygen-rich combustion two-stroke internal combustion engine specifically includes: a plurality of internal combustion engine bodies, the internal combustion engine body includes a cylinder 1, a piston 2, a piston rod 22, a cylinder head, a crankshaft 4, The space below the piston and the crankcase 3 located below the cylinder 1, the crankcase 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com