Preparation method of ceramic flame-retardant foamed silica gel material

A technology of ceramicized flame retardant and foamed silica gel, which is applied in the field of preparation of ceramicized flame retardant foamed silica gel materials, can solve the problems such as the inability to effectively guarantee the expansion of secondary combustion and runaway, and achieve excellent foaming uniform stability, Provides flame retardant, good production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

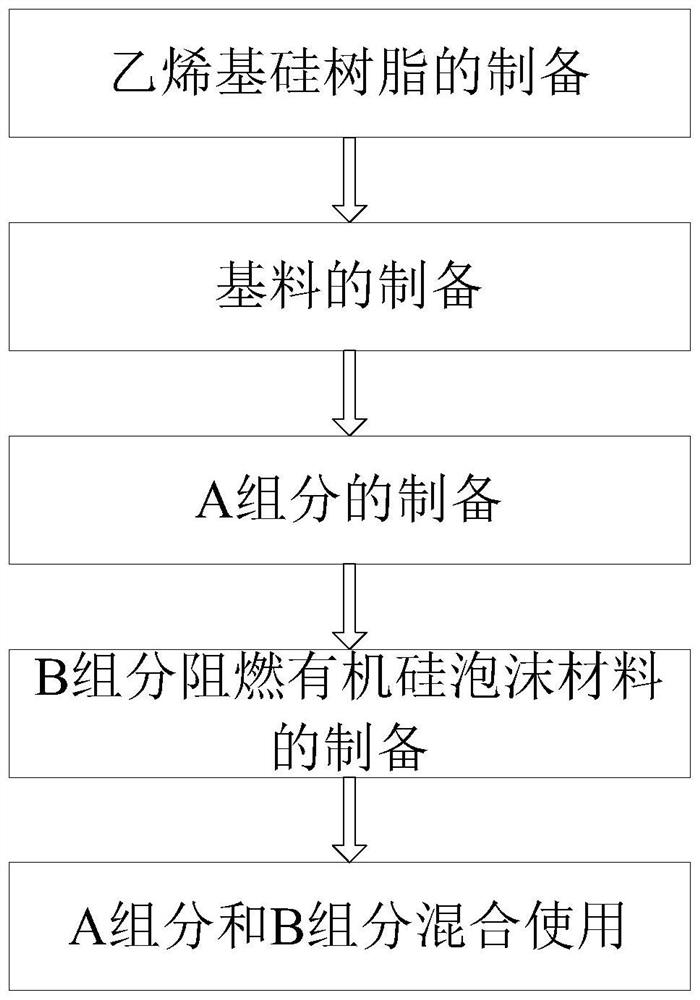

[0029] figure 1 It is a flowchart of an embodiment of a method for preparing a ceramic flame-retardant foamed silica gel material according to the present invention. As shown in the figure, the present invention provides a method for preparing a ceramic flame-retardant foamed silica gel material, which includes the following steps:

[0030] (1) The preparation of vinyl silicone resin comprises the following steps:

[0031] S1. Mix methyl orthosilicate, methyltrimethoxysilane, water glass, hydroxyl-terminated polydimethylsiloxane, and aluminum hydroxide according to the ratio of 40:30:5:15:10 and stir at high speed to disperse, add Potassium hydroxide 3ppm, gradually warming up to 60 degrees and constant temperature for 2 hours, airtight heating to 90 degrees and stirring and dripping into 5 parts of pure water to obtain prepolymer;

[0032] S2. Keep the above-mentioned prepolymer at 90 degrees for 30 minutes, then add 5 parts of vinyl double-capped heads, heat up to 130 degre...

Embodiment 1

[0039] The invention provides a method for preparing ceramic flame-retardant foamed silica gel material, comprising the following steps:

[0040] (1) The preparation of vinyl silicone resin comprises the following steps:

[0041] S1. Mix methyl orthosilicate, methyltrimethoxysilane, water glass, hydroxyl-terminated polydimethylsiloxane (107), and aluminum hydroxide in a ratio of 40:30:5:15:10 and stir at high speed Disperse, add potassium hydroxide 3ppm, gradually raise the temperature to 60°C and keep the temperature for 2 hours, heat up to 90°C in airtight, stir and drop in 5 parts of pure water to obtain the prepolymer;

[0042] S2. Keep the above-mentioned prepolymer at 90 degrees for 30 minutes, then add 5 parts of vinyl double-capped heads, heat up to 130 degrees in airtight, add 45 parts of pure water dropwise and stir for 3 hours, add phosphoric acid solution, and drop chlorine Phosphazene 100PPM stirring;

[0043] S3. Release the pressure, slowly turn on the vacuum ...

Embodiment 2

[0048] The invention provides a method for preparing ceramic flame-retardant foamed silica gel material, comprising the following steps:

[0049] (1) The preparation of vinyl silicone resin comprises the following steps:

[0050] S1. Mix methyl orthosilicate, methyltrimethoxysilane, water glass, hydroxyl-terminated polydimethylsiloxane (107), and aluminum hydroxide in a ratio of 40:30:5:15:10 and stir at high speed Disperse, add potassium hydroxide 3ppm, gradually raise the temperature to 60°C and keep the temperature for 2 hours, heat up to 90°C in airtight, stir and drop in 5 parts of pure water to obtain the prepolymer;

[0051] S2. Keep the above prepolymer at 90°C for 30 minutes, then add 10 parts of vinyl double-capped head, heat up to 130°C in airtight, add 45 parts of pure water dropwise and stir for 3 hours, add phosphoric acid solution, and drop chlorine Phosphazene 100PPM stirring;

[0052] S3. Release the pressure, slowly turn on the vacuum to greater than 0.9 ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com