Multi-head saw for cutting warming pipe

A technology of multi-head saws and heating pipes, applied in the field of multi-head saws, can solve the problems of high operating requirements for staff and lower production efficiency, and achieve the effects of saving manpower and material resources, improving production efficiency, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

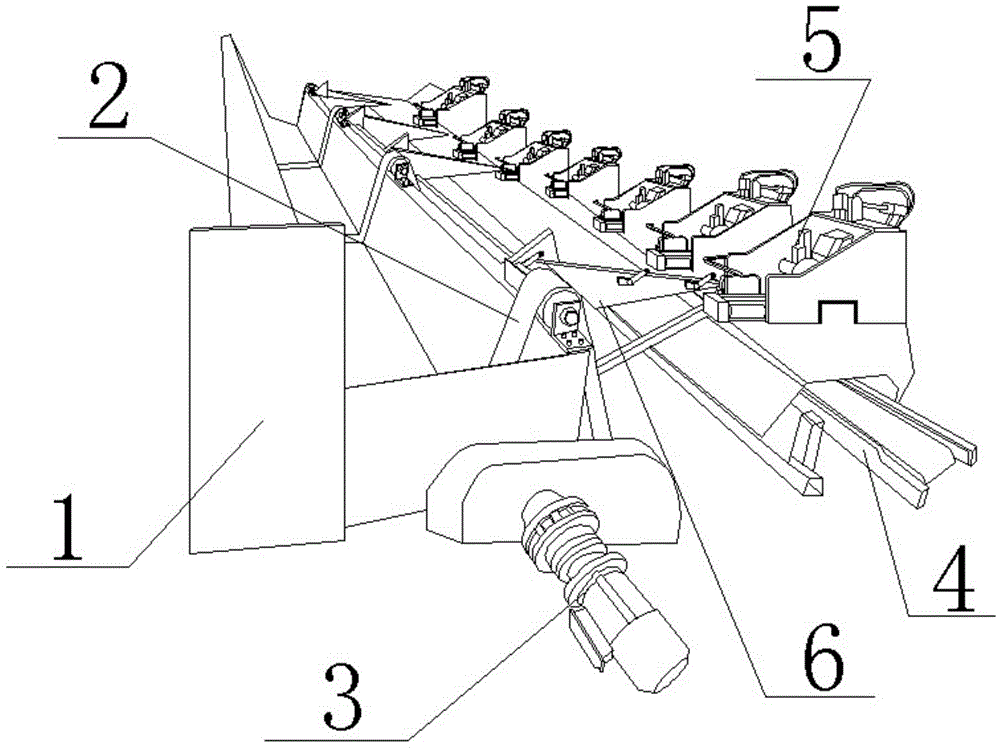

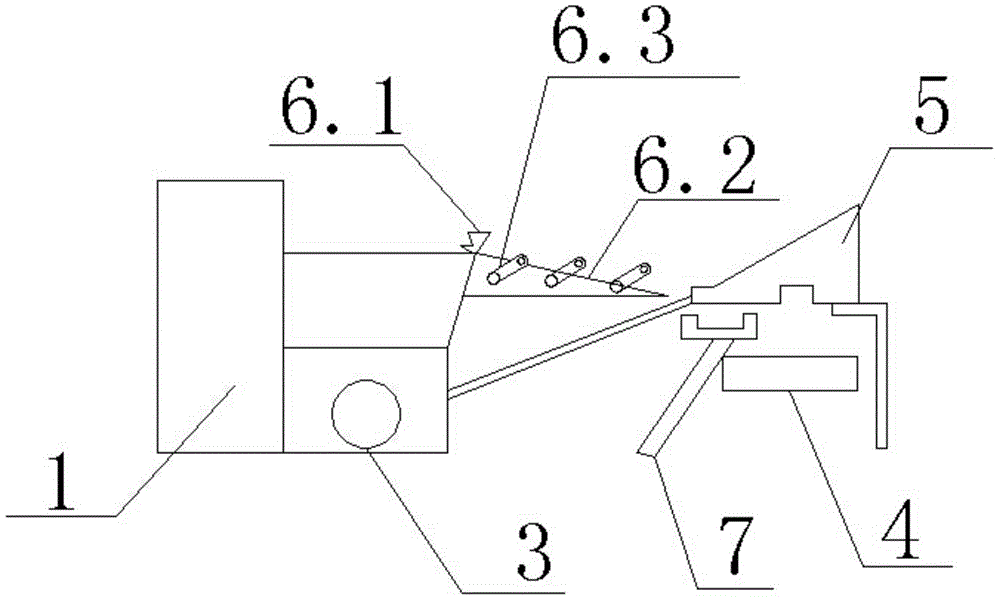

[0012] Such as figure 1 with figure 2 As shown, a multi-head saw for cutting heating pipes includes a pipe loading groove 1, a pipe lifting belt 2, a motor 3, a conveyor belt 4 and a cutting saw head 5, and a part of the pipe lifting belt 2 is arranged on the pipe loading In the slot 1, the other part is arranged on the motor 3, the motor 3 is installed below the front end face of the tube loading slot 1, and a blanking device is arranged between the tube loading slot 1 and the cutting saw head 5 6. The pipe lowering device 6 includes a pipe storage iron sheet 6.1, a pipe delivery frame 6.2 and three inductors 6.3. The pipe storage iron sheet 6.1 is installed on the side close to the pipe lifting belt 2, and the pipe delivery The frame 6.2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com