Radiation curing composition

A technology of radiation curing and composition, applied in the direction of ink, household appliances, pigment paste, etc., can solve the problems of low production efficiency, good adhesion, slow printing speed, etc., to achieve excellent production efficiency, excellent performance, excellent application sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Corresponding to the above-mentioned pigment dispersion, the present invention provides a preparation method of the pigment dispersion, comprising the steps of:

[0047] (1) Weighing pigment, dispersing aid and dispersing monomer in proportion, for subsequent use;

[0048] (2) Add the dispersing aid to the dispersing monomer, stir with a homogenizer until the dispersion is uniform, add the pigment and dispersing beads within 10 minutes, and then continue stirring until the cumulative particle size distribution number D90 and pH value of the pigment dispersion meet the requirements , stop stirring, and filter out the dispersed beads to obtain the pigment dispersion of the present invention.

[0049] As the medium used in the dispersion treatment, the dispersion beads can be selected from: ceramic microspheres such as zirconia, polymer balls such as polyethylene and nylon, and metal balls. From the viewpoint of abrasiveness, the dispersed beads are preferably zirconia mi...

specific Embodiment approach

[0142] The present invention will be described in further detail below in conjunction with specific examples, but they should not be construed as limiting the protection scope of the present invention.

Embodiment 19-42

[0173] ①Use the pigment dispersion obtained in Examples 1-6 to prepare a color density of 50% k.

[0174] According to the formula shown in Table 5, under the condition of 20-30°C, pre-mix cationic polymerizable compounds B1, B2, cationic photoinitiator C, and sensitizer respectively, and then mix the raw materials according to B1, B2, C , sensitizer, pigment dispersion, leveling agent BYK307, and defoamer BYK055 are added to the constant temperature and pressure reactor in sequence, and the mixer is used at 1500-2000rpm under the condition of yellow light (that is, a safety light that will not trigger the reaction) Stir under low pressure, and when the mixed solution is a homogeneous mixture by visual inspection, filter through a 5 μm filter to obtain the radiation-curable composition of Examples 19-24 of the present invention.

[0175] table 5

[0176]

[0177] Table 5,

[0178] B11 is I47;

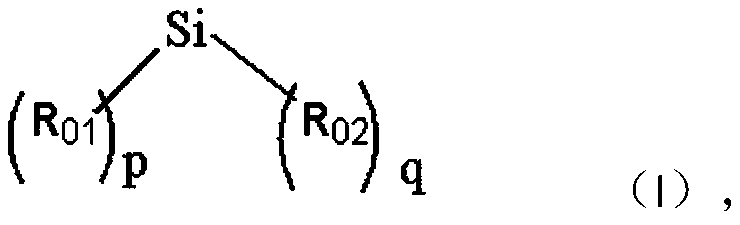

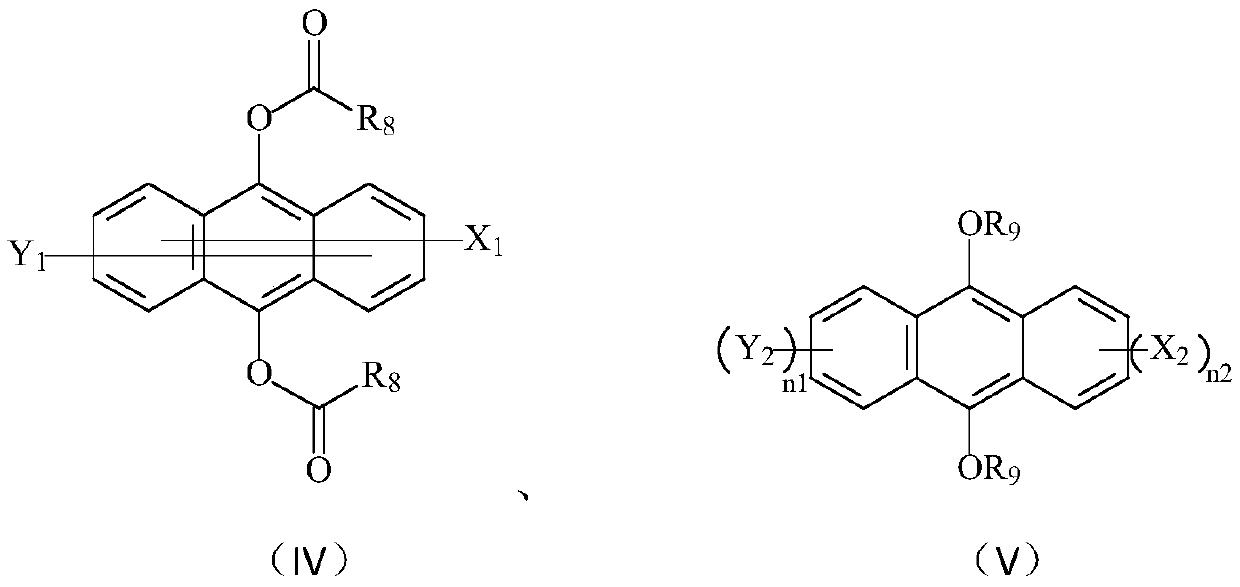

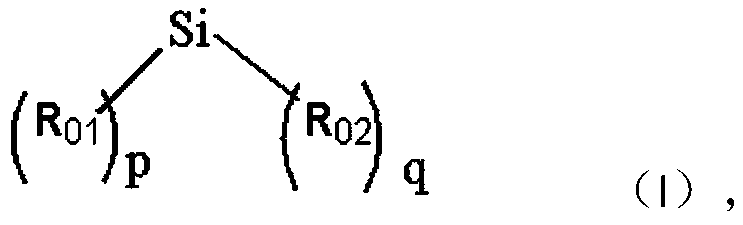

[0179] B12 is:

[0180] B13 is:

[0181] B21 is TTA2081 of Jiangsu Tait...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com