Biodiesel oil preparing process and apparatus

A preparation process and biodiesel technology, which are applied in the biodiesel preparation process and the field of devices thereof, can solve the problems of reducing the contact of reactant molecules, high energy consumption in the distillation process, and high requirements on oil quality, and achieve the improvement of reaction speed and reduction of finished product color and luster. , the effect of short distillation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific implementation plan

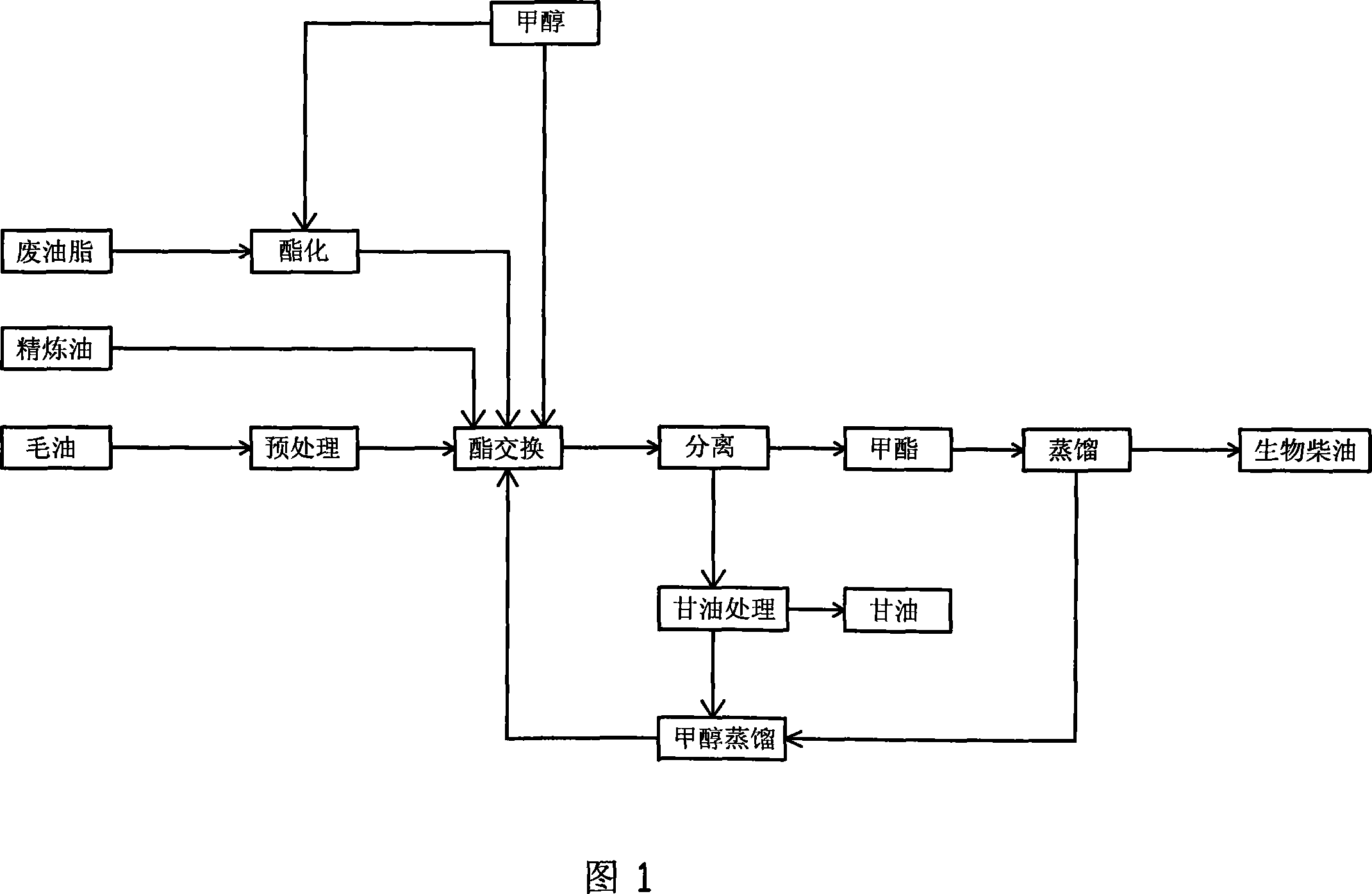

[0020] The process principle of the invention adopts the methanol vapor phase to enter the oil phase from the bottom by bubbling, and with the aid of mechanical stirring, the oil molecules and the methanol molecules are fully contacted and combined, which greatly accelerates the reaction speed.

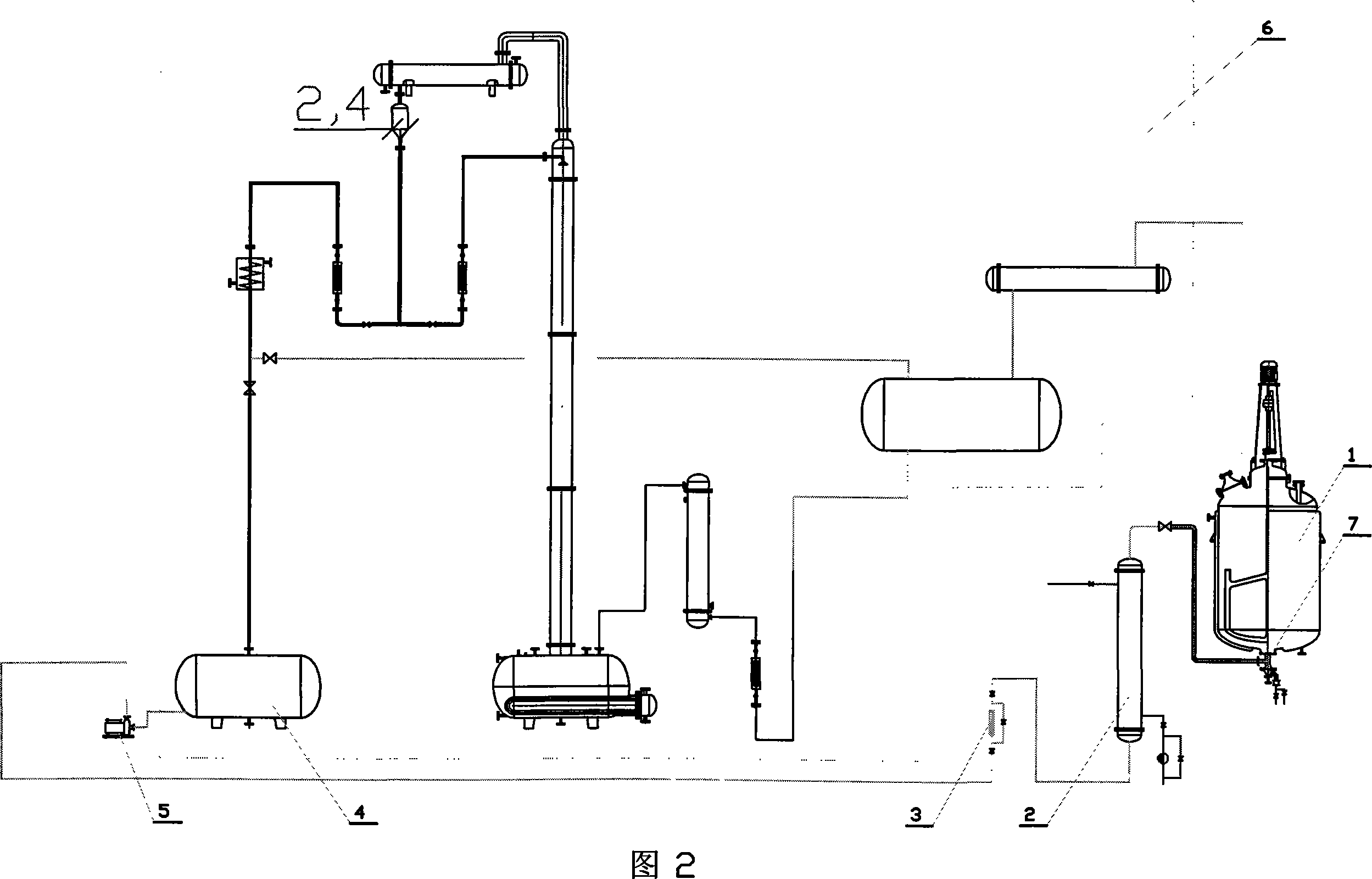

[0021] The process includes the esterification reaction, adding methanol, concentrated sulfuric acid and raw oil into the stirred reactor 1 and heating to carry out the esterification reaction. The process flow is shown in Figure 2. The said esterification reaction is supplemented by entering or refluxing. The methanol entering the reactor 1 is heated by the methanol steam generator 2 to become methanol vapor, and then enters the reactor 1 from the bottom of the reactor 1 through the valve 7.

[0022] The process equipment is shown in Figure 2, including a stirred reactor 1, a methanol recovery device 6, a qualified methanol receiver 4, a methanol pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com