Rapid molding apparatus

A molding equipment and fast technology, applied in the field of manufacturing, can solve the problems of falling off, unable to realize multi-material printing, etc., and achieve the effect of strong applicability and reduced dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

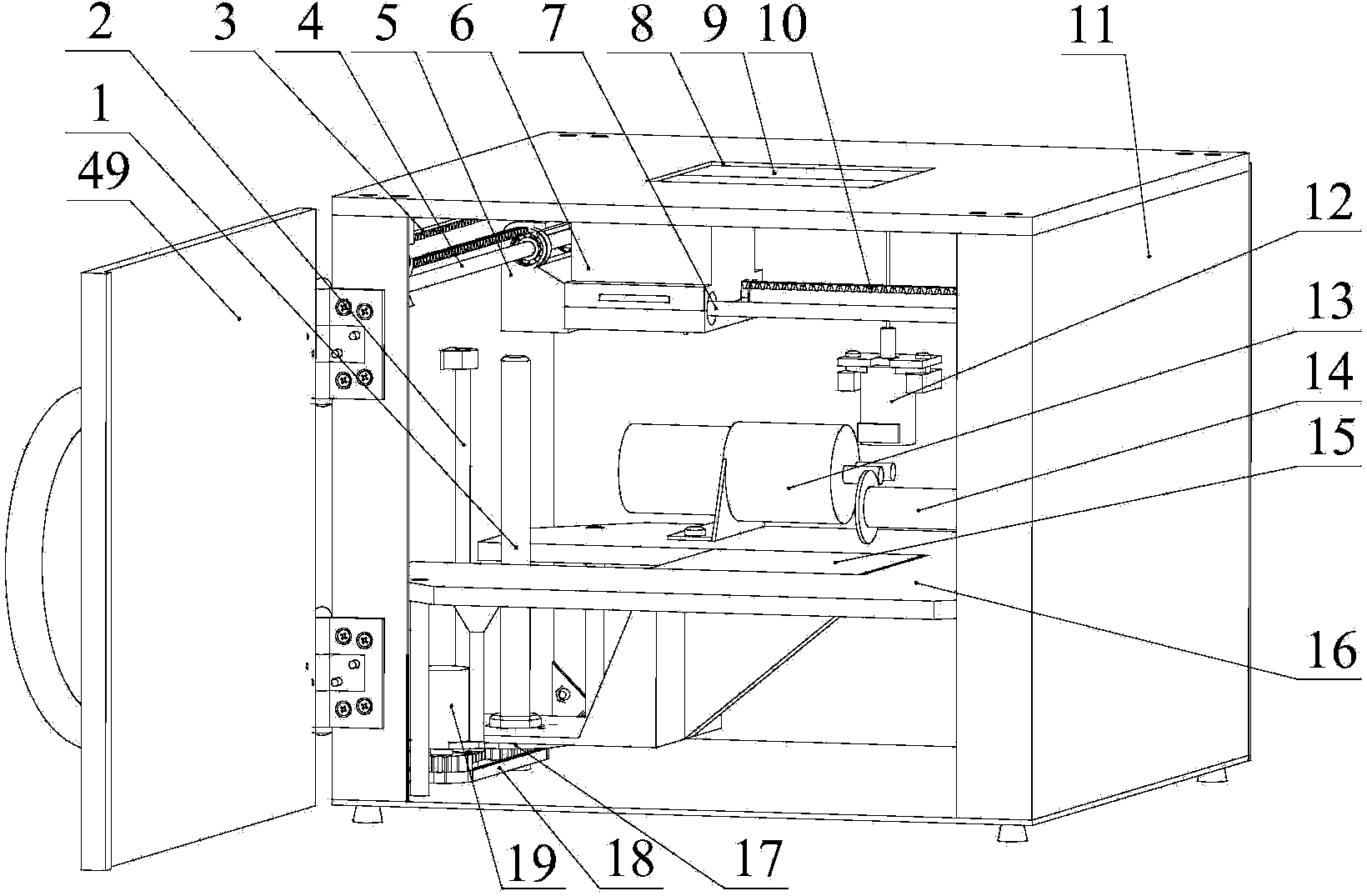

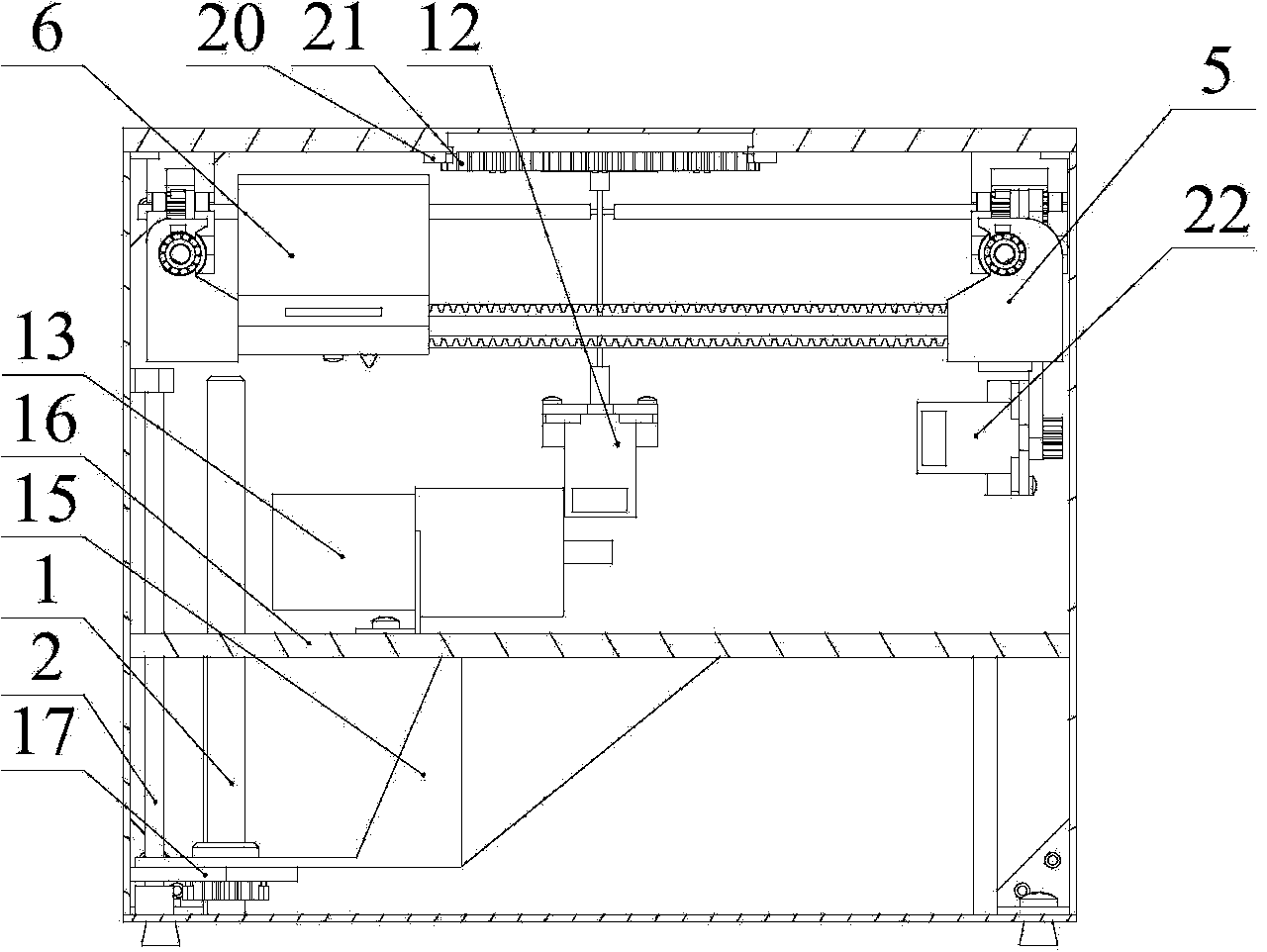

[0064] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0065] Such as figure 1 , 2 , shown in 3, a kind of rapid prototyping equipment, comprises the box body 11 of sealing structure, and one side wall of box body is dodge door 49, and the bottom of box body is provided with the printing panel 15 that can lift along the Z axis, is laid on the printing panel Silica gel film, the top of the printing panel in the box is provided with a printing head 6 and a moving mechanism that drives the printing head to move along the X-axis and the Y-axis direction. In this embodiment, the Z-axis direction is the vertical direction, and the X-axis, Y-axis, Z-axis The two shafts are perpendicular to each other, the print head 6 is detachably installed on the moving mechanism, and the top of the box is provided with an opening 8 for the printing panel to rise out of the box and a movable skylight for blocking the opening.

[0066] The movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com