Greek yogurt and preparation method thereof

A technology for Greek yogurt and strain, applied in the field of Greek yogurt and its preparation, can solve the problems of sour taste, strong back acid, single taste of yogurt, etc., and achieve the effect of ensuring taste, moderate acidity, and ensuring acidity and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

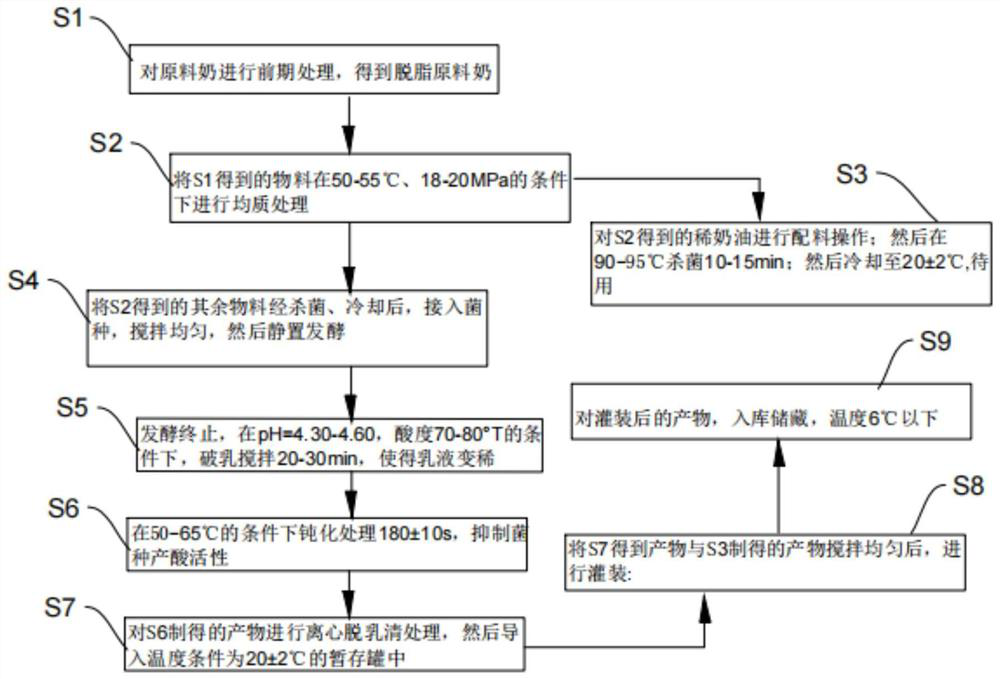

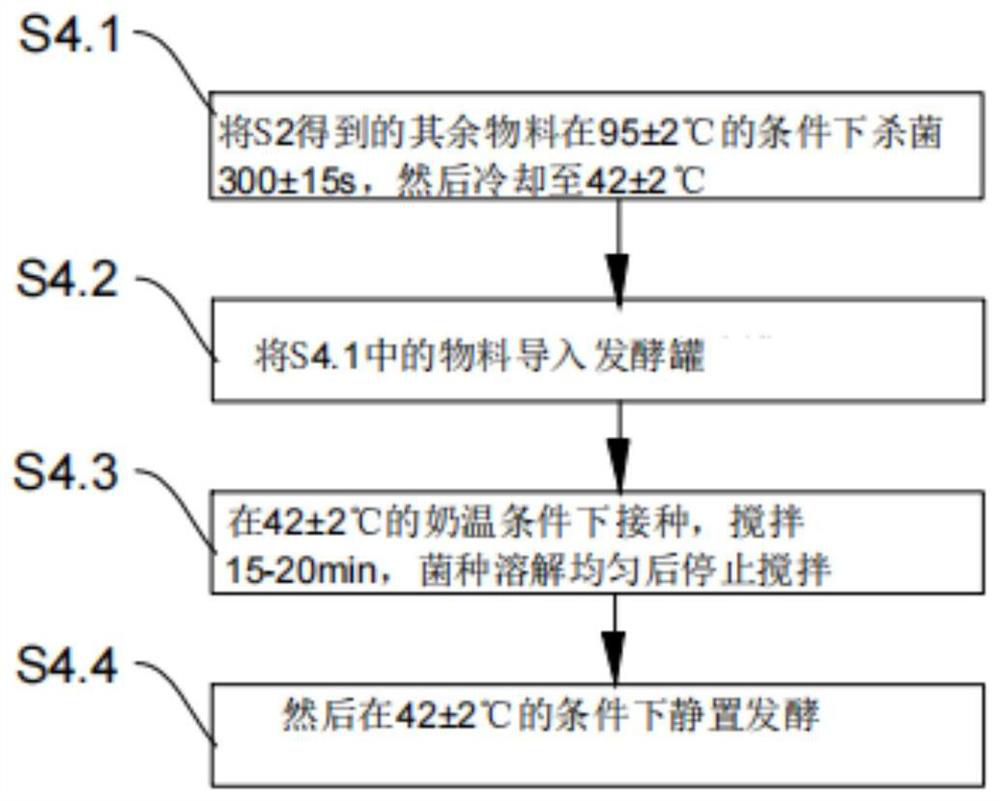

[0041] Please also refer to Figure 1 to Figure 3 , the preparation method of a kind of Greek yoghurt provided by the present invention is described now. The preparation method of described a kind of Greek yogurt, comprises the following steps:

[0042] S1. Pre-processing the raw milk to obtain skimmed raw milk;

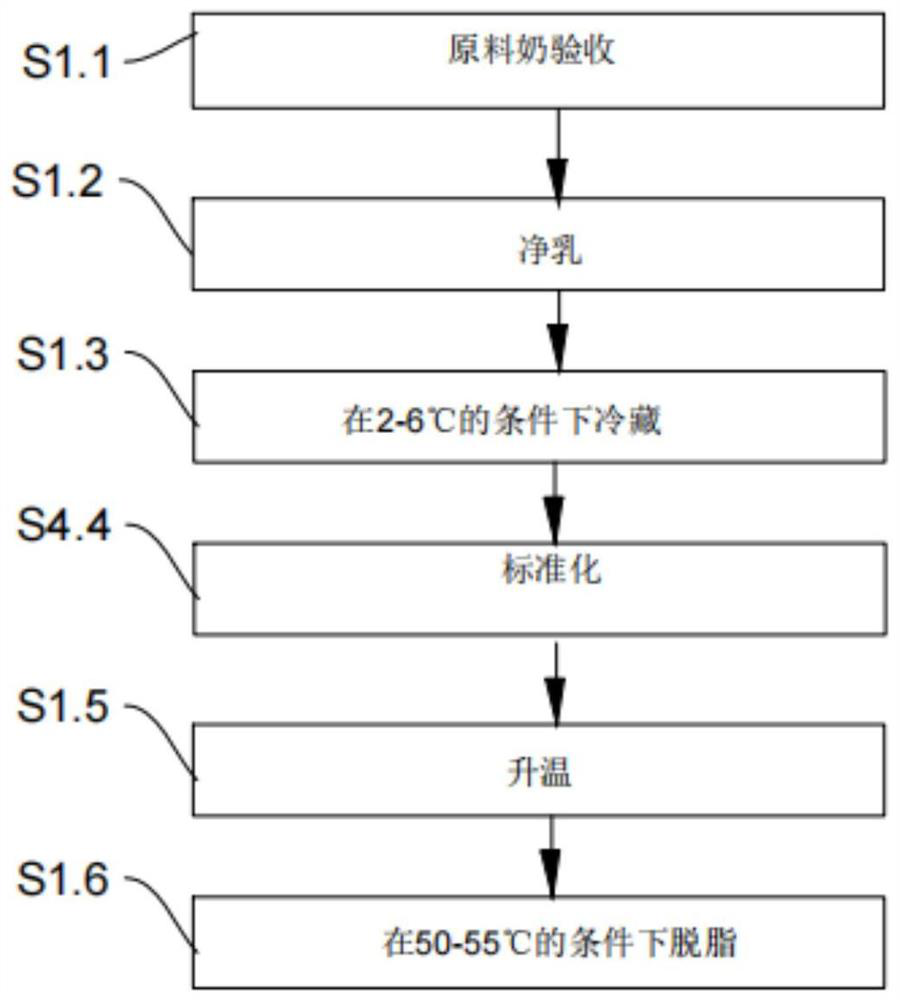

[0043] The implementation of step S1 can be as follows:

[0044] Step S1.1, raw milk acceptance;

[0045] Step S1.2, milk cleaning;

[0046] Step S1.3, refrigerating at 2-6°C;

[0047] Step S1.4, standardization processing;

[0048] Step S1.5, heating up to 50-55°C;

[0049] Step S1.6, degreasing under the condition of 50-55°C.

[0050] S2. Homogenize the material obtained in step S1 (i.e. skimmed raw milk) at 50-55°C and 18-20MPa;

[0051] S3. Perform batching operation on the cream obtained in step S2; then sterilize at 90-95°C for 10-15min; then cool to 20±2°C and set aside;

[0052] In step S3, the batching operation of the cream is to add dry matter to ...

Embodiment 2

[0082] In this example, a Greek yogurt prepared based on the preparation method described in Example 1 is provided. Compared with the prior art, the Greek yoghurt provided by the invention has the characteristics of moderate acidity and good smoothness.

[0083] Table 1. Comparative data of shelf life inspection of Greek yogurt products with different processes

[0084]

[0085]

[0086] Investigation data on shelf life of zero-fat Greek yogurt (2-6°C) passivation process preparation

[0087]

[0088] Investigation data on shelf life of zero-fat Greek yogurt (2-6°C) prepared without passivation process

[0089]

[0090] According to actual investigation and comparison, the Greek yogurt prepared by this process, with or without adding cream, has stable acidity data, stable number of active lactic acid bacteria, soft and delicate taste, moderate sweet and sour ratio, and no obvious whey precipitation within the shelf life , better texture and taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com