Anti-acid mist type battery filling cap

A battery and battery cover technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of reducing sulfuric acid content in electrolyte, reducing battery capacity, affecting battery use, etc., to ensure acid content, improve service life, The effect of reducing combustible gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

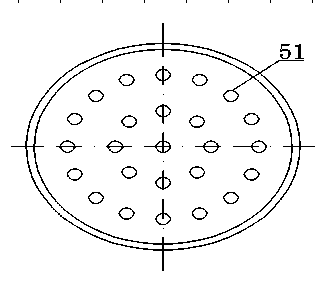

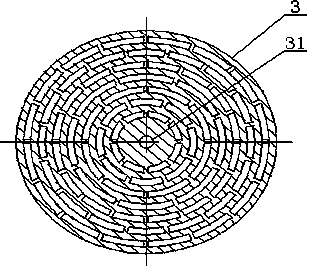

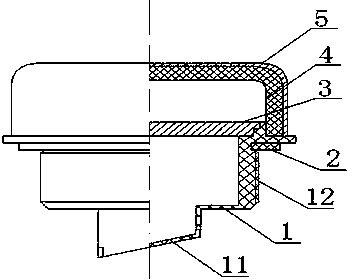

[0013] Such as figure 1 , figure 2 with image 3 As shown, an acid mist-proof battery liquid injection cover includes a cover body 1, the cover body 1 is sealed with the battery cover thread 12, and a sealing gasket 2 is provided between the cover body 1 and the battery cover; the cover body 1 The bottom is an inclined surface 11, the top surface is provided with a labyrinth circuit 3, the upper part is provided with a cap 5, and the cap 5 covers the labyrinth circuit 3 inside; There is a tapered return hole 31 with a small lower opening and a large upper opening. The cap 5 is provided with an air vent 51. The material of the anti-acid mist sheet 4 is PVC, which is densely covered with micropores.

[0014] During the use of the battery, when some water in the electrolyte is decomposed to form acid mist, the acid mist passes through the labyrinth circuit 3 and the formed droplets flow back into the battery through the return hole 31, and a small amount of acid mist that does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com