Flexible label laser marking machine

A laser marking machine and labeling technology, which is applied in the field of marking machines, can solve problems such as laser marking device and label misalignment, label scrapping, and increase production costs, and achieve the effect of improving accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

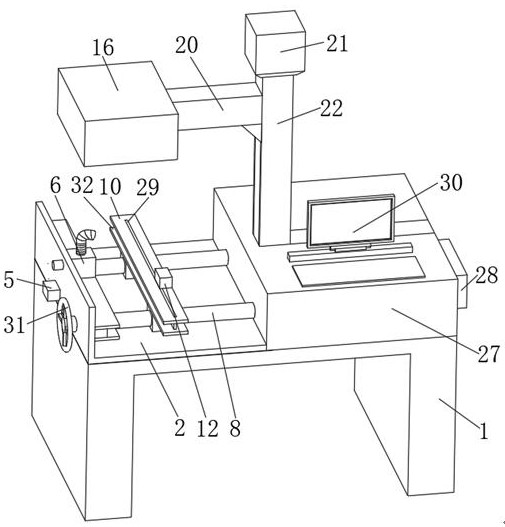

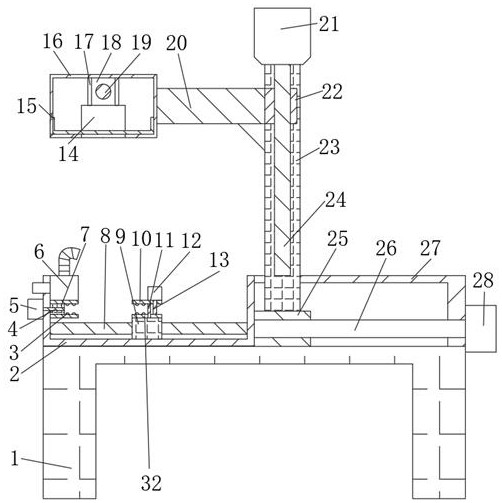

[0022] refer to figure 1 and figure 2 , a flexible label laser marking machine, including a laser device 14 and a base 1, the top of the base 1 is fixedly connected with a feeding plate 2, the top of the base 1 is provided with a clamping mechanism and a transmission mechanism, and the top of the clamping mechanism is provided with marking agency.

[0023] In the present invention, the transmission mechanism includes a screw rod 6 and a fixed column 8 that are rotatably connected to both sides of the feeding plate 2, and one end of the screw rod 6 is fixedly connected with a handle 31, and the bottom of the feeding plate 2 is slidably connected with two sliders Two 9, one slide block two 9 is threadedly connected to the side of the screw mandrel six, another slide block two 9 is slidably connected to the side of the fixed column 8, the side of the feeding plate 2 is fixedly connected with the box body 27, and the top of the box body 27 Fixedly connected with control device ...

Embodiment 2

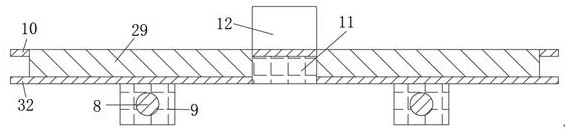

[0029] refer to figure 1 , figure 2 and image 3 , a flexible label laser marking machine, compared with Embodiment 1, in order to make the clamping mechanism play a better clamping effect, the bottom of the upper clamping plate 10 away from the feeding plate 2 is fixedly connected with a motor two The baffle plate one 11 below 12, the top of the lower clamping plate 32 is provided with the opening one below the baffle plate one 11, the top of the lower clamping plate 32 is fixedly connected with the second baffle plate 29, and the bottom of the upper clamping plate 10 is opened There is an opening two positioned above the second baffle plate 29 .

[0030] The bottom of the upper clamping plate 10 and the top of the lower clamping plate 32 are all fixedly connected with projections 3, and the side outer wall of the feeding plate 2 away from the slider two 9 is fixedly connected with the motor one 5, and the output shaft of the motor one 5 is fixedly connected with Screw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com